Chocoform® PSL

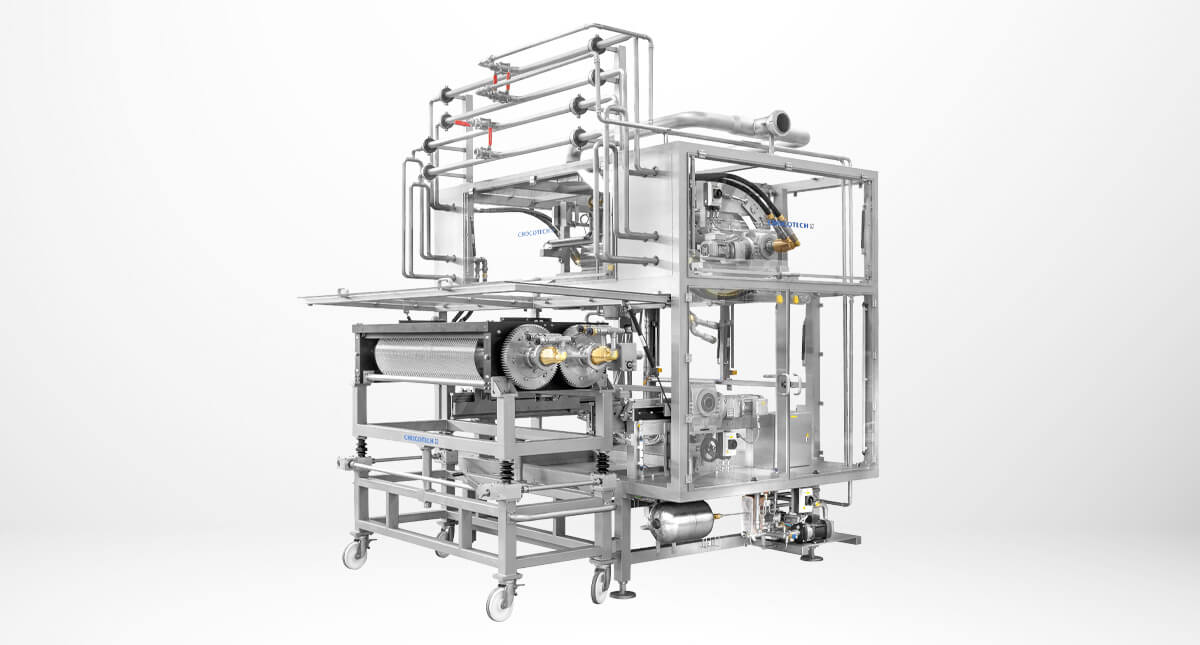

Chocoform PSL® is a drop roller system designed for manufacturing lentils, balls or chocolate eggs.

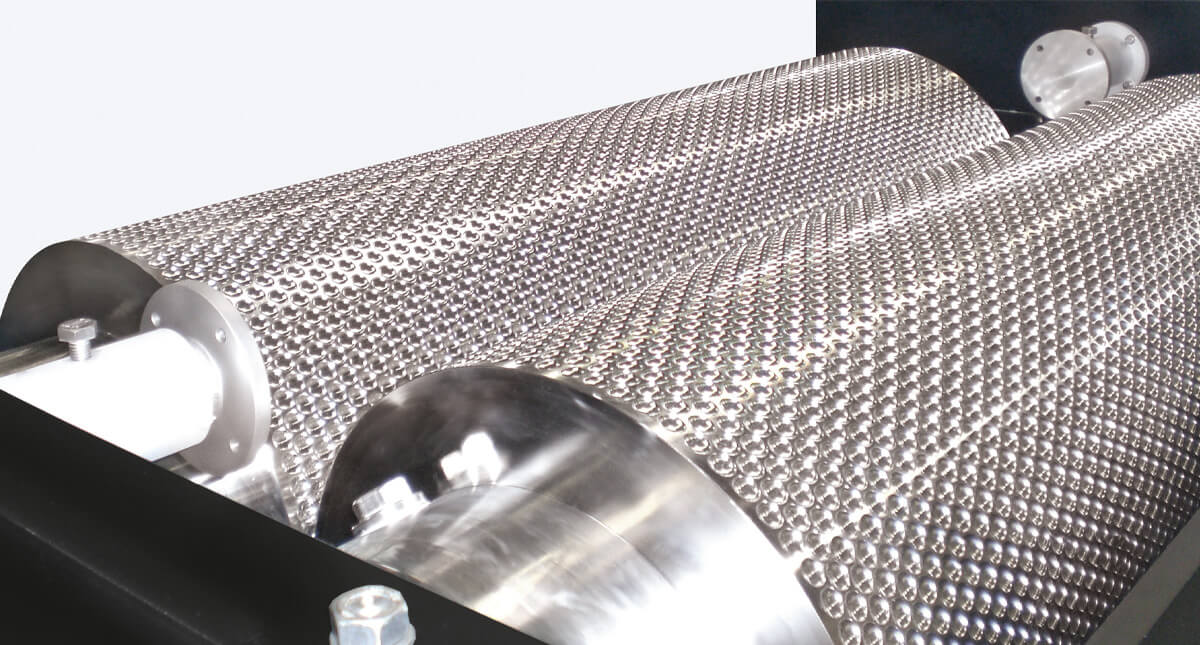

Tempered chocolate is fed between two cooled rollers and an embossed slab is formed. The system is designed for installation above a cooling tunnel infeed table and design allow for a quick product shape change over; wheel-in wheel out solution. The stainless steel jacketed drums are equipped with a special coolant flow to achieve a very precise temperature across the width of the drums. Gap adjustment for web thickness and product center alignment are easily adjustable. Both chocolate level between the rollers and angle of web to cooling tunnel belt are controlled by sensors to maintain precise control of system.

Working widths: 400, 600, 800, 1000, 1300 mm

Capacities: 200, 300, 400, 500, 700 kg/h

A special execution with pre-cooling (patent pending) allows for a 100% increase in throughput

CHOCOTECH also manufacture the downsteam corresponding equipment such as slab breaker, belt feeders, hygienic de-flash drum and rework return system.

Characteristics

- Weight-accurate shaping

- Quick format change

- Easy cleaning

Specifications

| Type | Category | Working width | Throughput* |

| Chocoform® PSL | Chocolate | 420 mm | 200 kg/h |

| Chocoform® PSL | Chocolate | 620 mm | 300 kg/h |

| Chocoform® PSL | Chocolate | 820 mm | 400 kg/h |

| Chocoform® PSL | Chocolate | 1050 mm | 500 kg/h |

| Chocoform® PSL | Chocolate | 1300 mm | 700 kg/h |

* – product-dependent