IDA-X

IDA-X is a perforated coating pan with fully automatic installation for sugar and sugarfree coating.

PRODUCTS RANGE

A wide range of centers

- Dried fruits, seeds, nuts…

- Toffees, caramels, liquorish…

- Biscuits, extruded products

- Chewing gums and chewy candies

A wide range of coatings

- Any type of syrup, sucrose, dextrose

- All polyols

- Dry powders, icing sugar…

- Waxing, glazing, varnishing

| Machine type | 502X | 1002X | 2002X | 3002X |

| Useful volume (liters) | 650 | 1300 | 2600 | 3900 |

| Batch size (kg) | 250-500 | 500-1000 | 1000-2000 | 2000-3000 |

| Drum diameter (mm) | 1600 | 1600 | 1800 | 1900 |

| Drum length (mm) | 1600 | 2900 | 4200 | 5600 |

| Bed depth (mm) | 450 | 450 | 540 | 630 |

SYRUP SPRAYING

Syrup preparation

- Modular custom design

- Hot or cold solutions with various ingredients, gum, gelatin, starch, color, flavor…

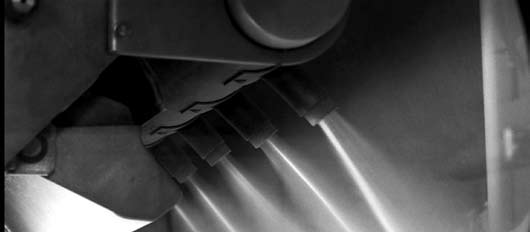

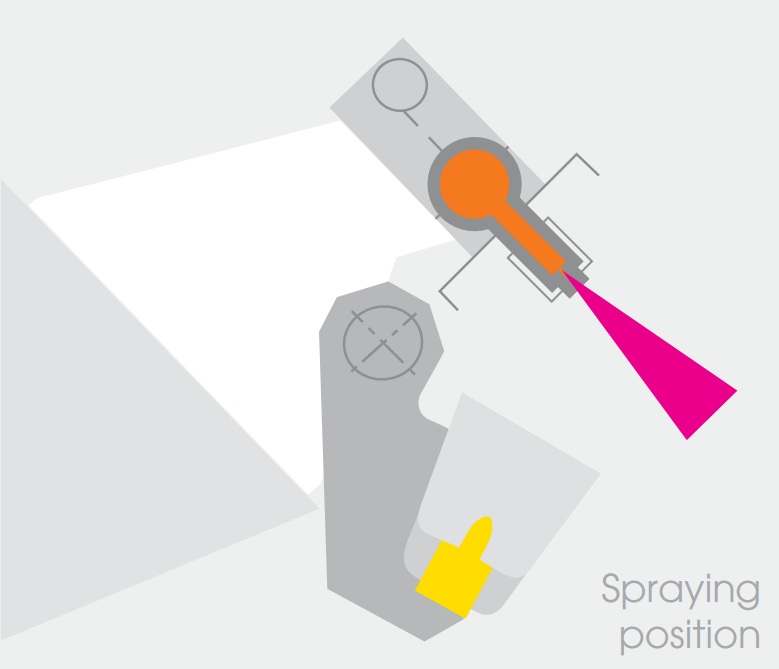

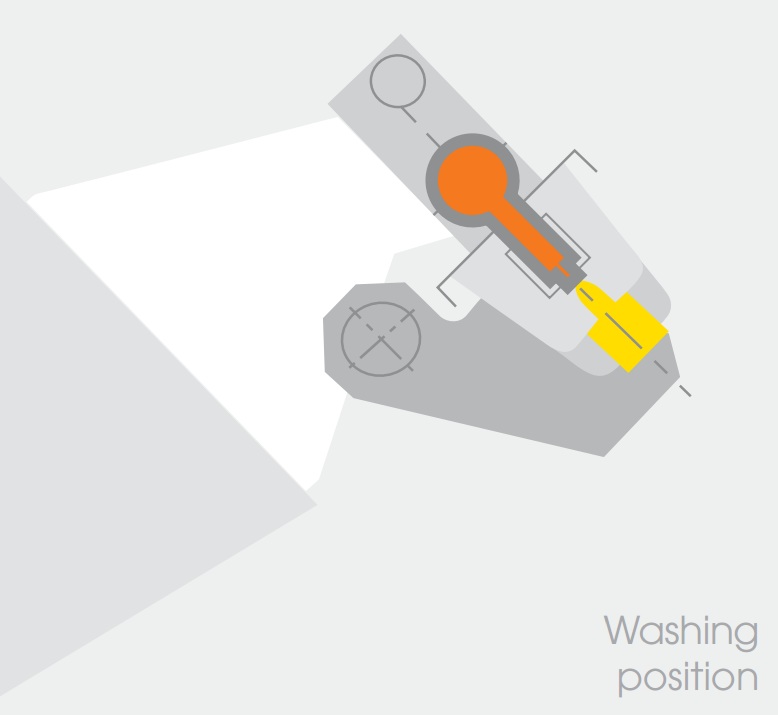

Syrup dosing and spraying

- High accuracy and consistency, with lobes pump and flowmeter

- Double jacketed networks

- Spraybar extraction for easy maintenance

- Spray nozzles automatic cleaning

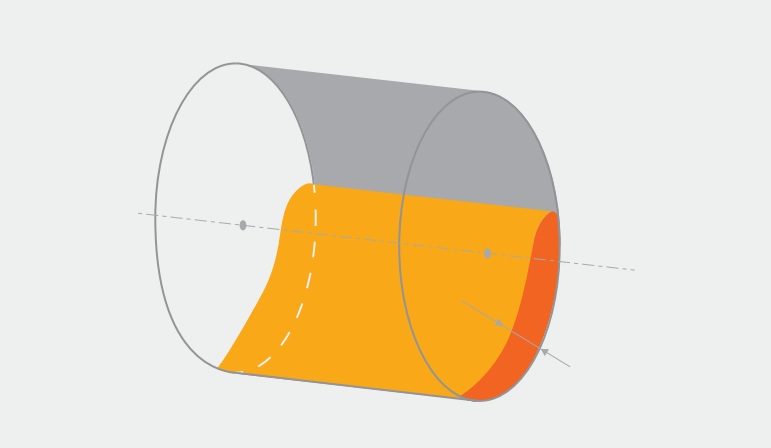

DRUM DESIGN

Fully perforated drum

- Suitable for hard sugar coat,sugarless coat, glazing or varnishing

- Air flow through products bed

- Low pressure drop for better efficiency

- Faster drying time

Shallow bed depth

- Elongated drum shape for lower bed depth

- Careful handling of fragile products

- Better mixing

- Better exposure to ventilation and spraying

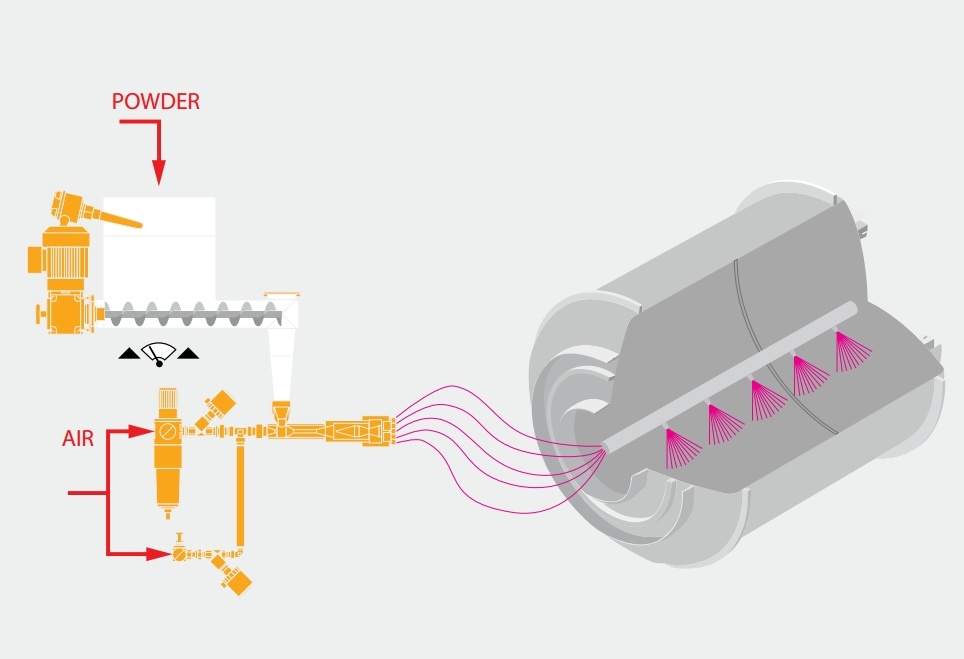

POWDER DISTRIBUTION

- To help crystallization for coating with polyols

- To cover products with cocoa powder, icing sugar…

- Accurate system with powder dosing / weighing and compressed air powder transport

VARNISHING AND WAXING

- Varnishing solution tanks: for aqueous and alcoholic solution

- Varnish dosing systems: for controlled steps

- Varnish spraying systems in the pan: with airless spray guns

- Micronised carnauba wax distribution: with air spray system

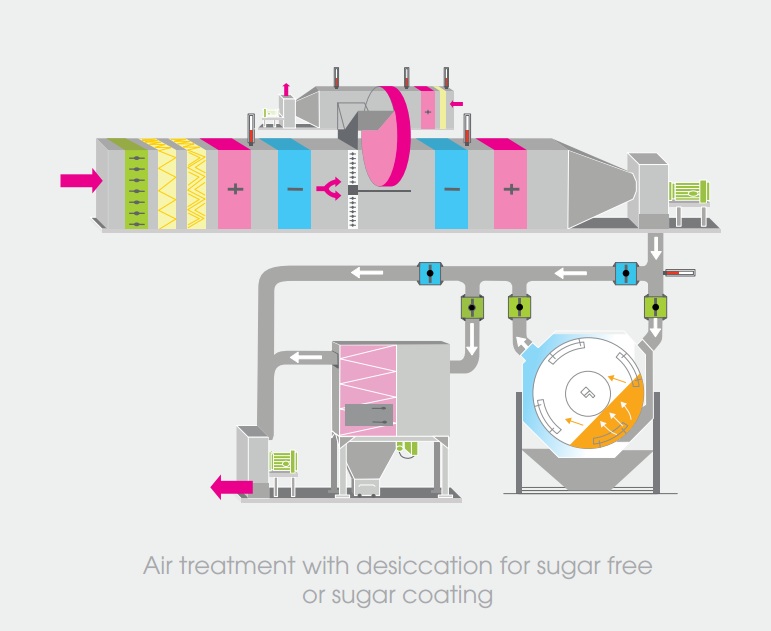

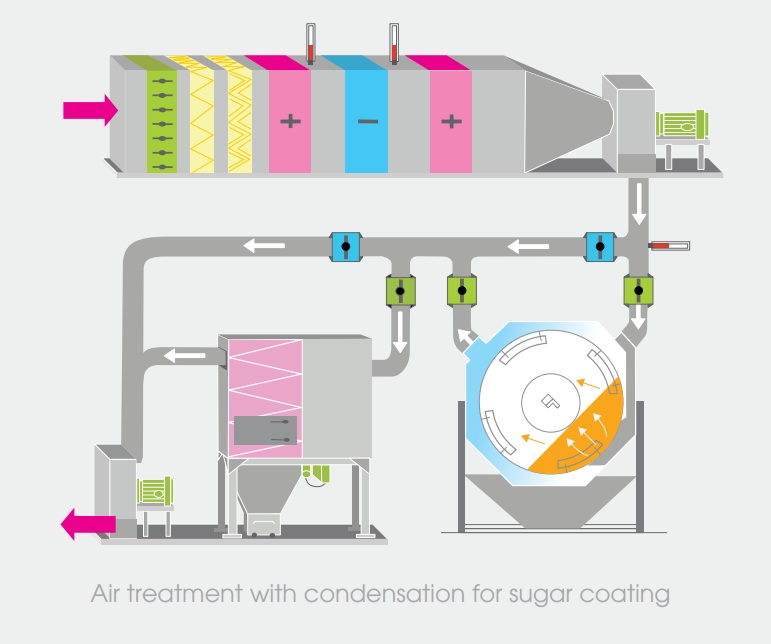

AIR TREATMENT GROUP

| Machine type | 502X | 1002X | 2002X | 3002X |

| Airflow (m3/h) | 4500 | 9000 | 18000 | 27000 |

Process Air

- Airflow, temperature and humidity control

- Perfect repeatability

Exhaust air

- Negative pressure inside pan

- Automatic cleaning

- Dust collection

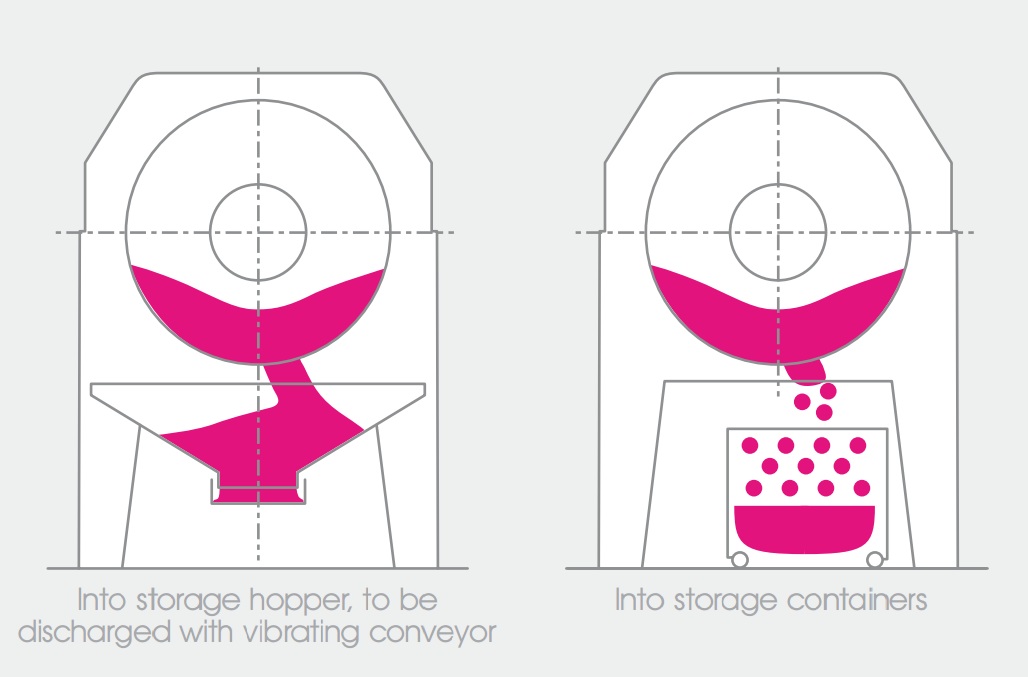

UNLOADING SYSTEM

Fast unloading system by traps allowing start of next batch very quickly

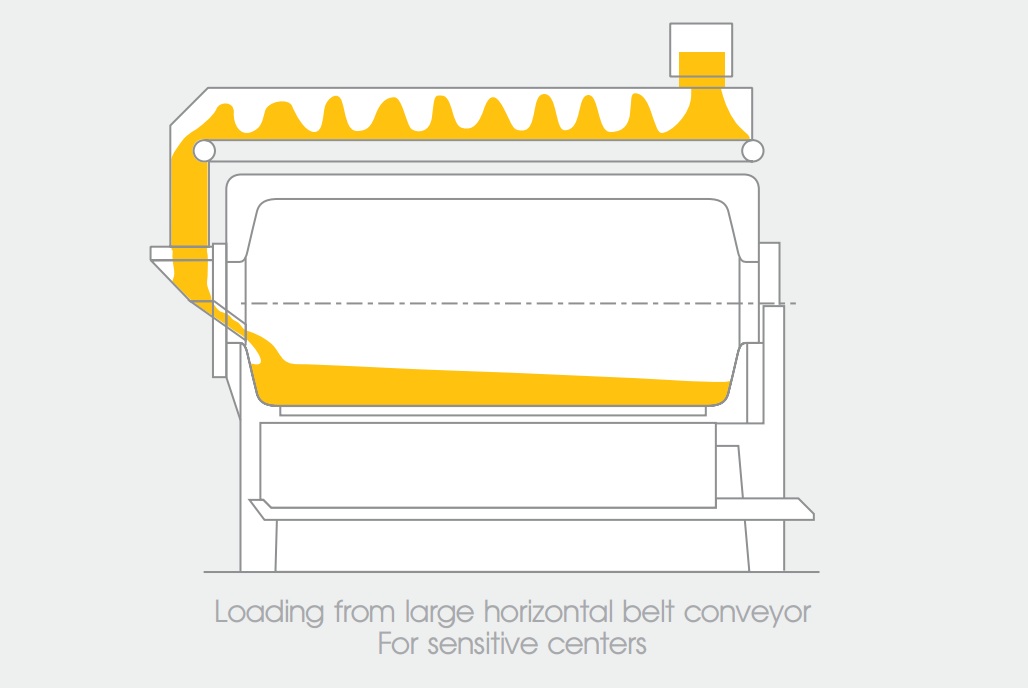

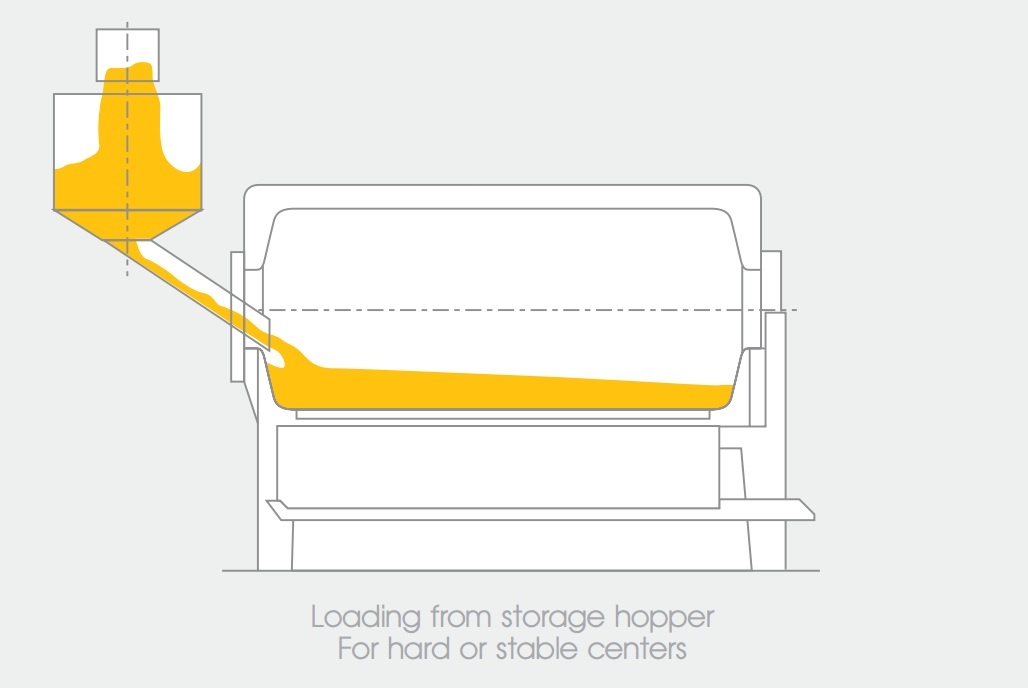

LOADING SYSTEM

Custom design solutions

- According to products fragility

- Adapted to batch size and facility layout

- Wide range of dosing conveyors, elevators, belts

- Automatic fast loading system

DEVELOPMENT AND ASSISTANCE

- Industrial scale laboratory

- Equipped with 250kg and 500kg coating machines

- Recipe development with your products

On-site assistance

- Operators and maintenance staff training

- Process development and improvement

AUTOMATION

Effective control of the coating process with different possibilities

IDA PROG3

The basic solution for quality coatings with simple machine handling

- Automatic coating cycle according to programmed recipes

- Semi automatic controls for loading, unloading and washing functions.

IDA PROG4

Fully automated system allowing to customize all machine parameters

- Automatic coating cycle according to user-friendly recipe building module

- All functions run from operator terminal including programmable sequences

- Overview screens for installation status

- Possibility to network with other machines and supervision system

IDA PROG5

The ultimate process, production and quality control. Supervisory Control and Data Acquisition (SCADA)

- Batch data recording and displaying

- Historical trends and fault reports

- Recipes dowload to IDA coaters

- Real-time overview of networked coaters

Product Brochure

Dumoulin-Perforated-Coating-Pan-IDA-X.pdf