LogiX

LogiX small scale automatic systems are specially adapted for hard and soft sugar coatings on fragile centers, such as chewy paste, licorice or chewing gums, as well as more resistant products such as chocolate lentils, nuts or hard candies.

PRODUCTS RANGE

A wide range of centers

- Dried fruits, seeds, nuts…

- Toffees, caramels, liquorish…

- Biscuits, extruded products

- Chewing gums and chewy candies

A wide range of coatings

- Any type of syrup, sucrose, dextrose

- All polyols

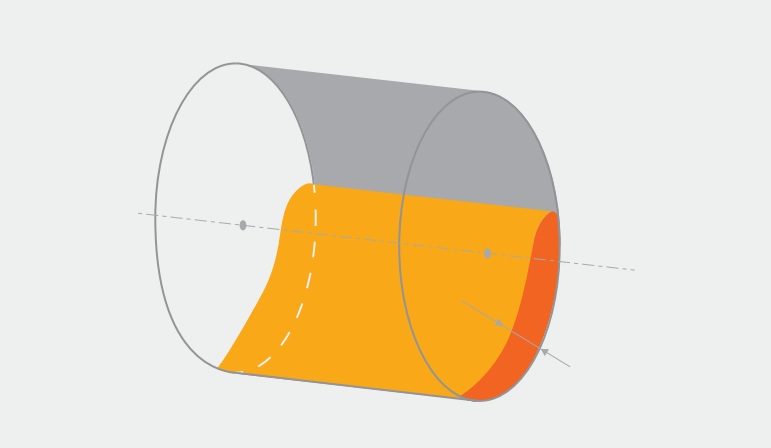

DRUM DESIGN

| USEFUL VOLUME | 329 Liters |

| BATCH SIZE | 100-250 kg |

| DIAMETER | 1400 mm |

| LENGTH | 940 mm |

| PRODUCT BED DEPTH | 357 mm |

Fully perforated drum

- Suitable for hard sugar coat, sugarless coat.

- Air flow through products bed

- Low pressure drop for better efficiency

- Faster drying time

Shallow bed depth

- Elongated drum shape for lower bed depth

- Careful handling of fragile products

- Better mixing

- Better exposure to ventilation and spraying

SYRUP SPRAYING SYSTEM

Syrup dosing

- High accuracy and consistency, with lobes pump and flowmeter

- Double jacketed networks

Syrup spraying

- Spraybar extraction for easy maintenance

- Spray nozzles automatic cleaning

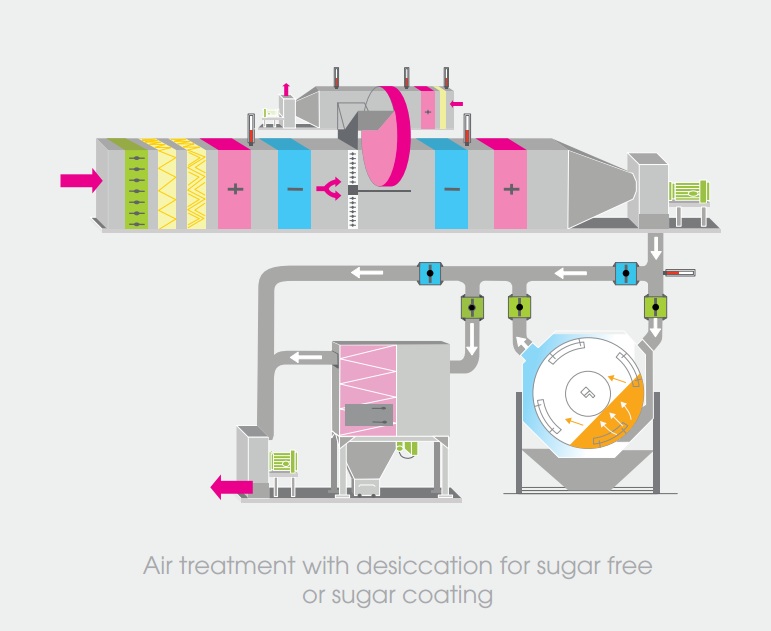

AIR TREATMENT GROUP

Process Air

- Airflow, temperature and humidity control

- Perfect repeatability

- Ventilation on top of products bed

Exhaust air

- Negative pressure inside pan

- Automatic cleaning

- Dust collection

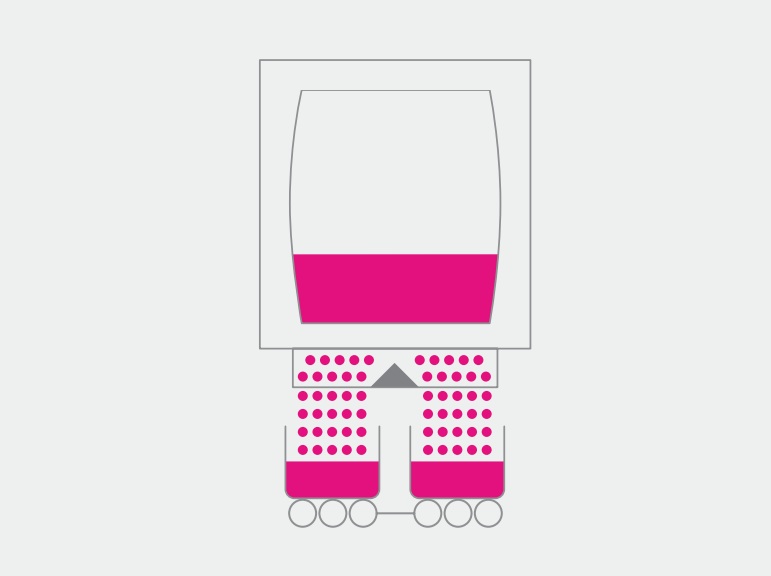

UNLOADING SYSTEM

Fast unloading system by traps allowing to start next batch very quickly. Finished products are unloaded into Eurobin containers for easy handling.

AUTOMATION

Automatic coating process according to recipes built with the touch screen and stored in the system

Product Brochure

Dumoulin-Minicoater-Logix.pdf