Sollcotop®

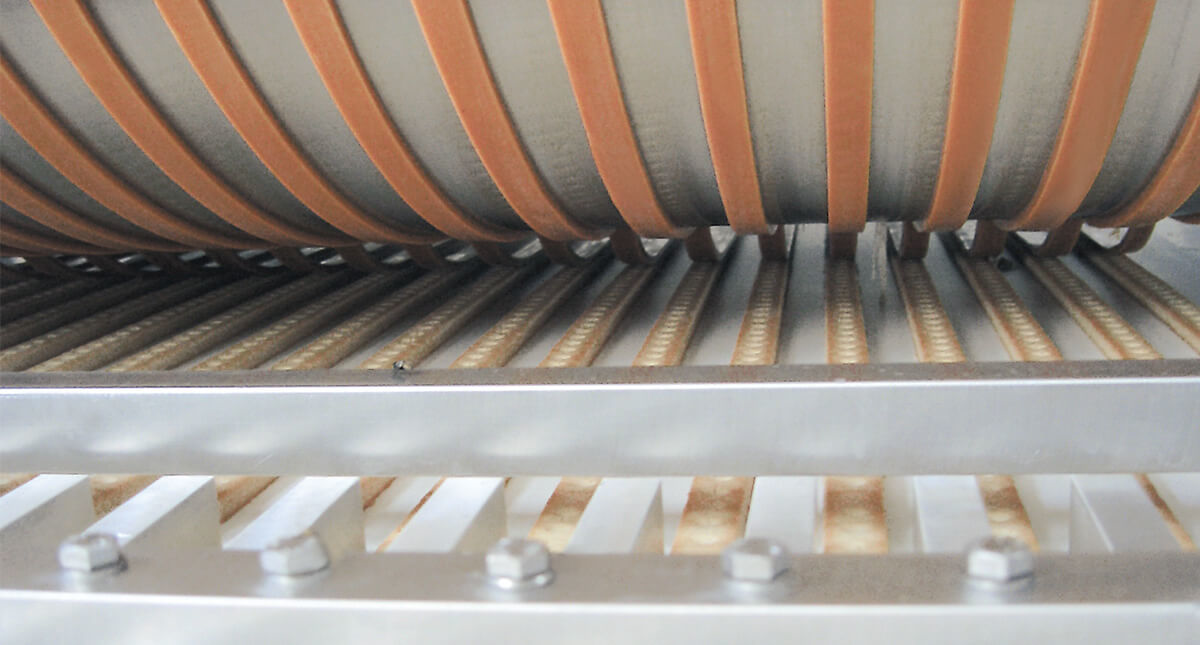

Sollcotop® is a new method of chocolate enrobing for either half-coated products or for strip coating.

Sollcotop® is suitable for almost all fluid enrobing materials, such as chocolate, compound of hot or cold icings.

Sollcotop® is the ideal enrobing system for all flat biscuits and baked articles.

Manufactured in working widths from 400 to 1800 mm and for operating speeds up to 12 m/min.

Outstanding characteristics of the Sollcotop®

- Exactly calibrated enrobing thickness produces very accurate enrobed weight

- No contamination of the product base with the coating material

- Maintenance and interruption free operation

- There is no wire belt as is the case with chocolate enrobers

- Easy and swift change of material without time consuming machine cleaning

- Where chocolate coating is concerned, you require a tempering machine capacity equal only to what you use

- Low investment cost

- Low energy demand by efficient technology using energy saving components (e.g. IE3 motors)

Additional equipment

As well as the option to extend the enrobing line by the addition of a THERMO-FLOW® Plus cooling tunnel, a comprehensive range of extra equipment is available:

- bottom coaters and pre-coating machines

- sprinkling devices operating from above or polydimensionally

- the DECORMATIC® automatic decorating system, Type DC4

- decorating rollers

- biscuit turn-over device

- product depositor and removal device

- truffle depositors

- truffle powdering and spiking stations

- cluster formers

- forming and extruding systems for pralines and bars

- chocolate tanks and pumps

Product Brochure

Sollich-Sollcotop.pdf