Turbotemper ® e TE / TE-D

Since the invention of the SOLLICH Circulation Tempering Process 60 years ago, there has been no more significant breakthrough in chocolate pre-crystallization than the Turbotemper ® e (Evolution) tempering machine from Sollich.

The Turbotemper® e (TE) brought clarity to the physical occurrences during the tempering process and disputes many of the previously known options. The Turbotemper® e (TE) proves its exceptional tempering quality not only with pure cocoa butter chocolates, but also chocolates with a high percentage of milk fat cocoa butter equivalents (CBE’s). Even pure cocoa butter can be successfully pre -crystallized. The “First-In-First-Out” principle of the Turbotemper ® e guarantees a constant, defined residence time. The patented mass and water flow is the basis for efficient heat exchange with low energy consumption. The low mass content offers advantages during changeovers.

Characteristics

- Increased shelf life and exceptional gloss due to presence of a very high proportion of stable beta V crystals

- Improved heat resistance of chocolate

- Lower viscosity as a result of 2-3 ºC (3-5 ºF) higher operating temperatures

- Constant degree of temper, even with varying chocolate infeed temperatures or throughputs

- Uniform hollow good shells, reduced breakage and thinner, pinhole free chocolate coating

- Improved contraction for easier demoulding and less mould cleaning

- Quickest solidification during the cooling process (post recrystallisation)

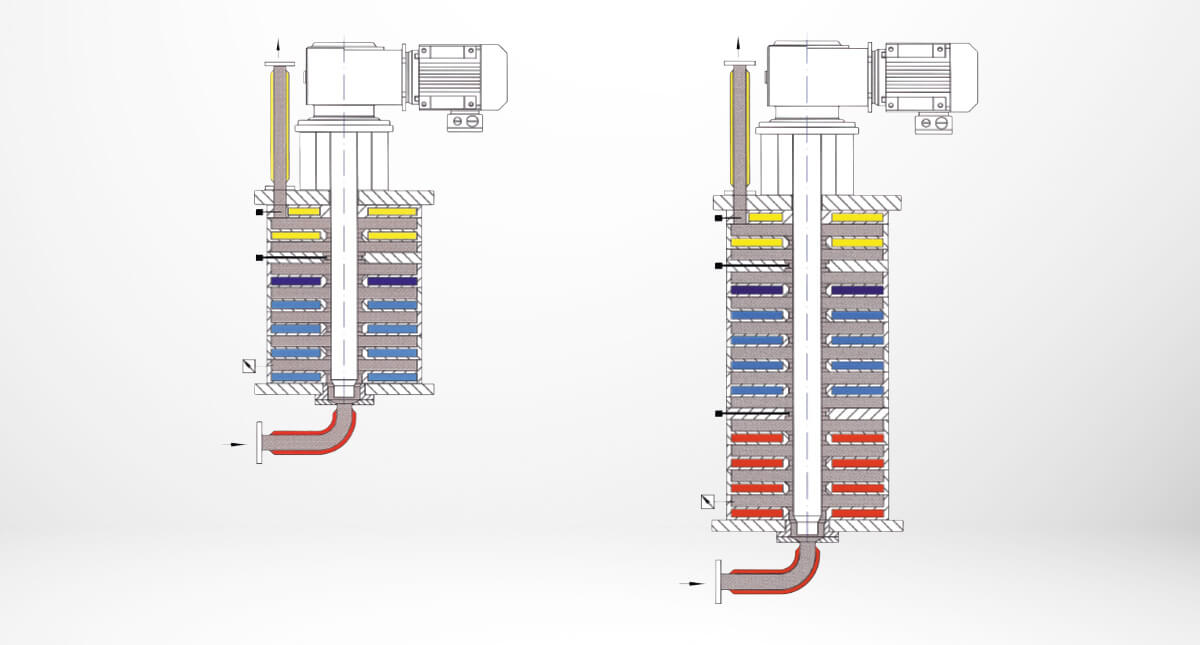

- available with pre-heating/de-tempering zone (TE-D execution)

Advantages

- Better temper quality through accelerated crystal formation and absolutely homogeneous crystal distribution due to the new “Mäander” double scraper (patented)

- Accelerated cooling and pre-crystallisation because there is less volume of chocolate in each of the plates and because the “first-in/first-out” route for the chocolate is guaranteed

- Greater economy trough and increased tempering throughput made possible by the new design double channel cooling plates (patented)

- High percentage of uniform, stable beta crystals formed in the crystallization stage, thanks to the uniformity of temperature of the cooling surfaces (patented). The temperature is automatically adjusted according to the chocolate throughput

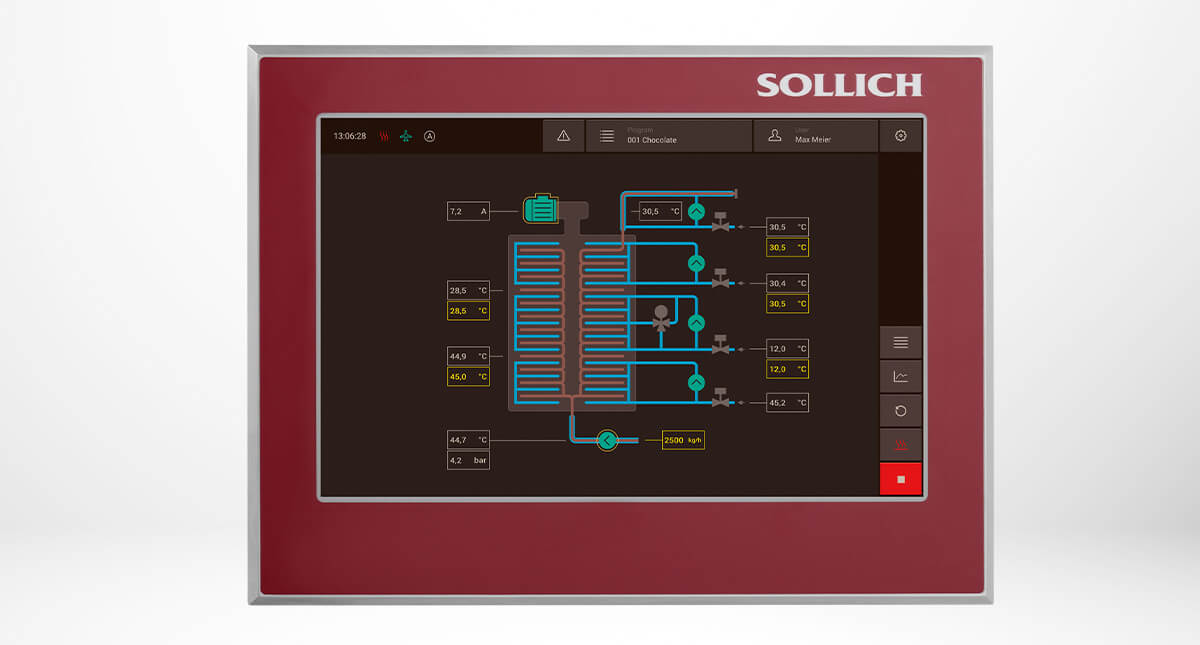

- More accurate chocolate temperature control by measuring the temperature in an annular gap (patented)

- High degree of user comfort, extensive data availability such as Tempermeter curves and preventative maintenance advice possible, upon request, by means of a Touchscreen HMI

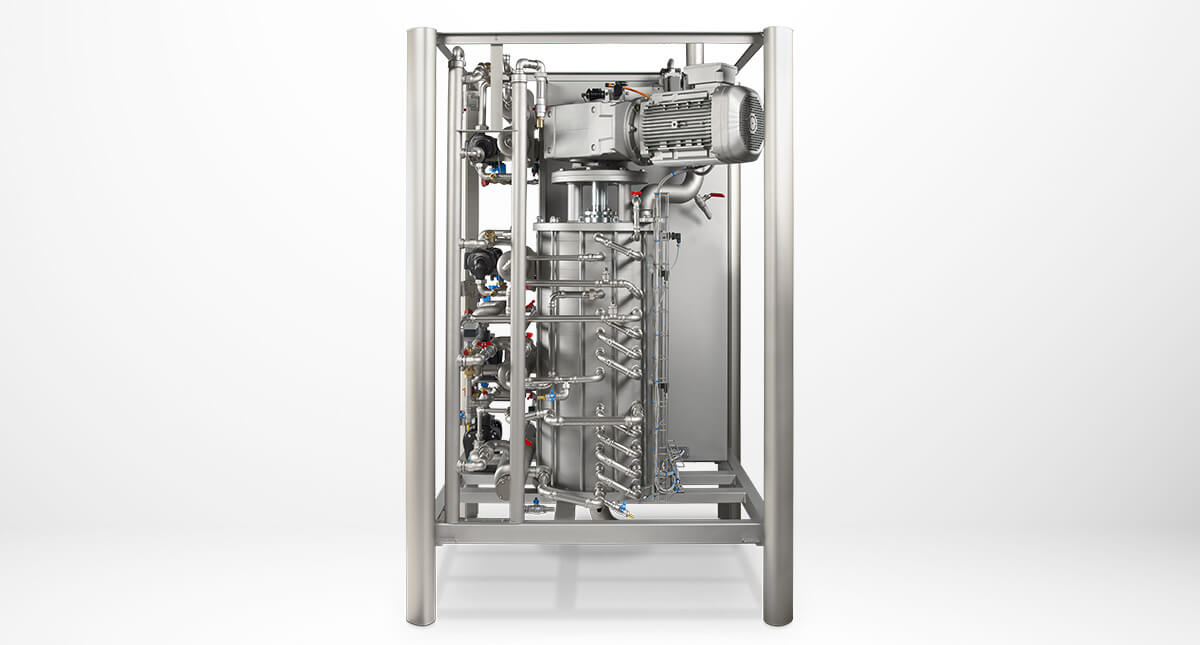

- Hygienic design with stainless steel piping

- Low energy demand by efficient technology using energy saving components (e.g. IE3 motors)

Alternative Versions

Sollich Turbotemper® e TE and TE-D machines are available for tempering at output rates from 100 to 19,000 kg/h.

- Turbotemper® e TE – Standard Turbotemper® from 750 to 19,000 kg/h

- Turbotemper® e TE-D – With built-in de-crystallization stage. It heats or cools the chocolate to a constant temperature of 45° C. For tempering output rates from 100 to 8,000 kg/h.