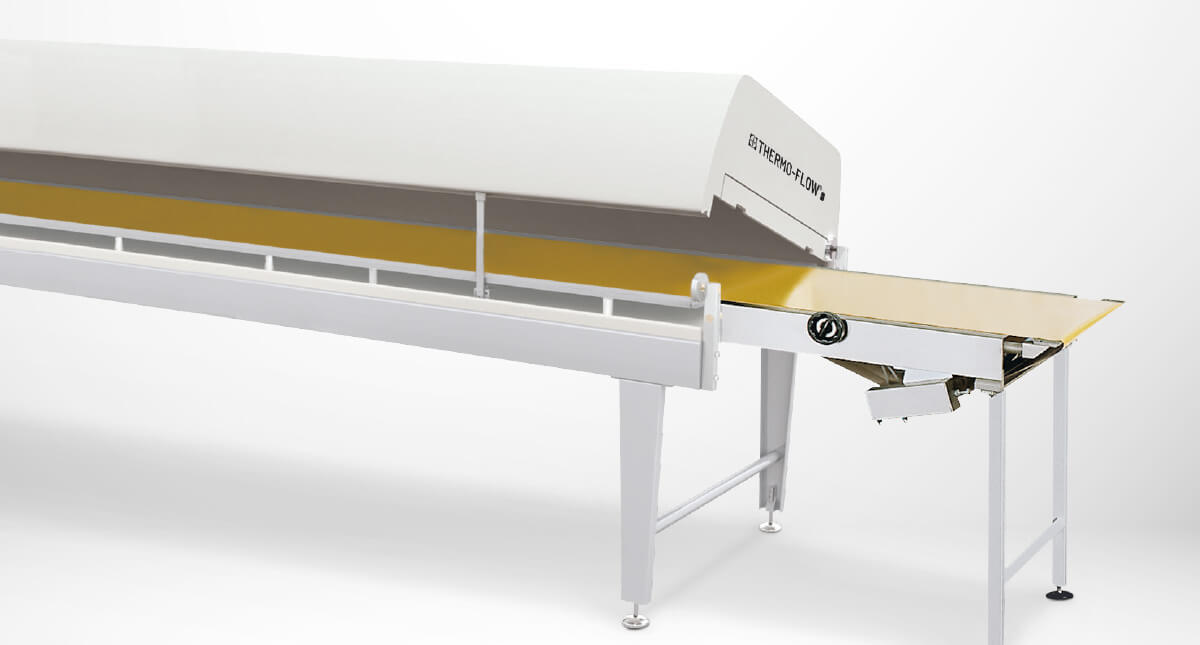

Thermo-Flow® + type KK

The Thermo-Flow®+ cooling tunnel KK is specially designed for center cooling. Increased convection cooling from the top and cold water contact cooling at the bottom provide intensive cooling. The cooling tunnels are designed as a modular system and consist of sections 3 m in length. Because of their precision fit, the polyurethane hoods are airtight without the need for a seal. Energy-saving CFC-free insulation is of course a standard feature, and the equipment naturally complies with GMP guidelines.

The cooling principle

The high-performance cooling tunnel operates with more intense convection cooling from above and intensive cold water contact cooling below. The two cooling systems can be regulated independently of one another.

Fields of application

With their combination of more intense convection cooling from above and cold water cooling from below, Type KK Thermo-Flow® plus cooling tunnels have been specially designed for cooling product fillings.

SOLLICH Thermo-Flow® plus cooling tunnels are available in belt widths from 320 mm to 3000 mm (12″ to 118″) and in lengths of up to 100 m (328 ft).

Features

- Convection cooling with air and bottom cooling with water

- High efficiency due to low energy losses

- Uniform temperature and air flow adapted to the product requirements

- Construction without cold bridges

- Optimum accessibility for cleaning and maintenance