EK3

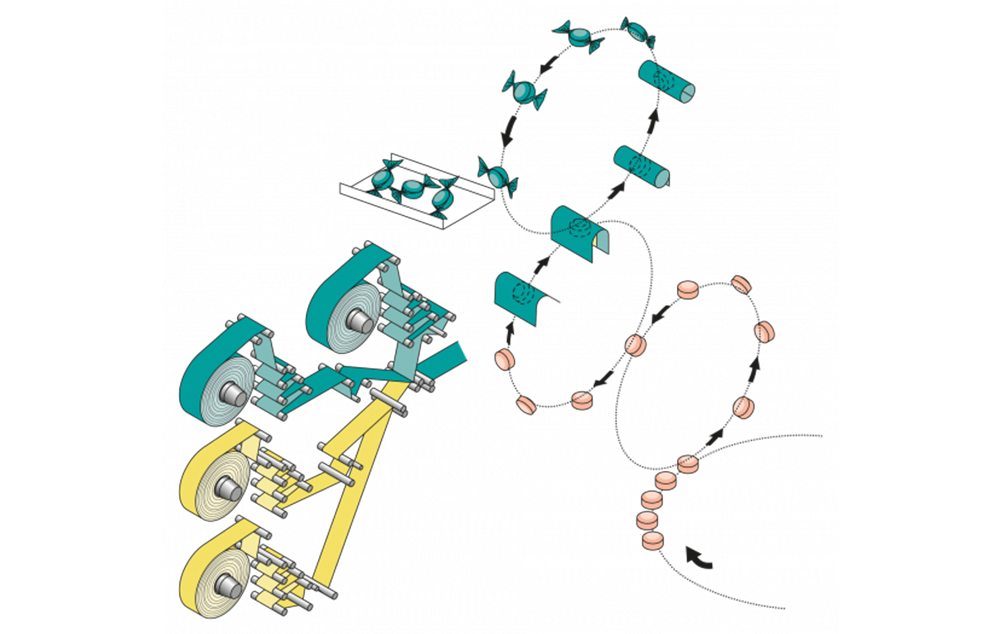

High-speed wrapping machine for preformed products in double twist. The continuous motion principle of the machine enables efficient and reliable high-performance wrapping of mass production.

Product Characteristics

Folding type

- Double Twist

- Protected Twist

Products

- Products suitable for plate feeding

- Hard Candys (with or without center-filling)

- Eclair

- Toffees

Product dimensions

- Length: 16 – 40 mm

- Width: 12 – 25 mm

- Height: 6 – 20 mm

Disc shape products

- Ø 13 – 28 mm

- Special design up to diameter: 33 mm

- Height: 6 – 20 mm

Ball shaped products

- Ø 17 – 23 mm

Output

- Up to 1800 products/min

Technical Data

Utilities

- Connected load: 13 kVA

- Compressed air consumption: 2m³/h; 600 kPa

Measurements

Machine:

- Length: 3080 mm

- Width: 2730 mm

- Height: 1880 mm

Switch cabinet:

- Length: 1200 mm

- Width: 500 mm

- Height: 1960 mm

Weight

Machine:

- 2250 kg without inner wrapper

- 2550 kg with inner wrapper

Switch cabinet:

- 350 kg

Wrapping material

- Wax paper

- Cellophane

- Polypropylene

- Polyethylene

Material dimensions

- Reel diameter: Up to 400 mm

- Reel width: Up to 120 mm

- Core diameter: 70 – 76,2 mm

Equipment & Options

Special features

- A particularly gentle handling of the products is guaranteed by the continuous motion principle

- Highly efficient feeding system with integrated sorting station to eliminate sugar dust, chips and broken pieces

- Servo control with PLC functions

- Air support to allow the use of PP foils

- Saving of wrapping material by “no product – no paper” device

- Automatic splicer to change wrapping material reels without stopping the machine

- Ejection of spliced, mal-registered and unwrapped products

- Infinitely variable adjustment of the twist gripper oscillation depending on the wrapping material quality

- Adjustment of the twisting angle in three steps (1,1; 1,6; 2,1 rotations)

- Different executions of the twist grippers for different wrapping materials

- Servo-driven wrapping material feed rollers and wrapping material knife

- Pneumatic core locking and reel tensioning devices

- All electrical and electronic components are located in a separate switch cabinet

- Excellent accessibility for operation, maintenance and cleaning purposes

- Easy operation due to the touch screen

- Due to the automatic operation, several machines can be handled by one operator

- System of protection: IP 54

Combinations

- Beside manual feeding, the machine can be directly synchronized to the production line by means of a Theegarten-Pactec feeding system.

Optional extras

- Photo-electric print registration

- Additional reel holders for a second wrapping material (under strip) with automatic splicer

- Special execution for moulded toffees

- Remote diagnostics

- Optional device for hermetically sealed, airtight packages (“Protected Twist”)

Product Brochure

EK3_ENG_19_1_web.pdf