Temperstatic® T6

SOLLICH built the first enrobing machine with integral circulation tempering in 1956. This was a huge success, with well over 1000 plants world-wide. The circulation process patented back then enabled the viscosity of the chocolate to be maintained at a constant level for the first time and allowed enrobing machines to be operated for long periods without interruption. This resulted in greater consistency of coating weights and more economical use of chocolate. Continuous development over the years has culminated in the TEMPERSTATIC® T6 machine in our current range, which combines the TURBO tempering process with the SOLLICH circulation tempering process in a single unit.

Fields of application

The machines are suitable for full, half or bottom-coating of pralines, bars, pastries etc. with chocolate.

Outstanding characteristics of the TEMPERSTATIC® T6:

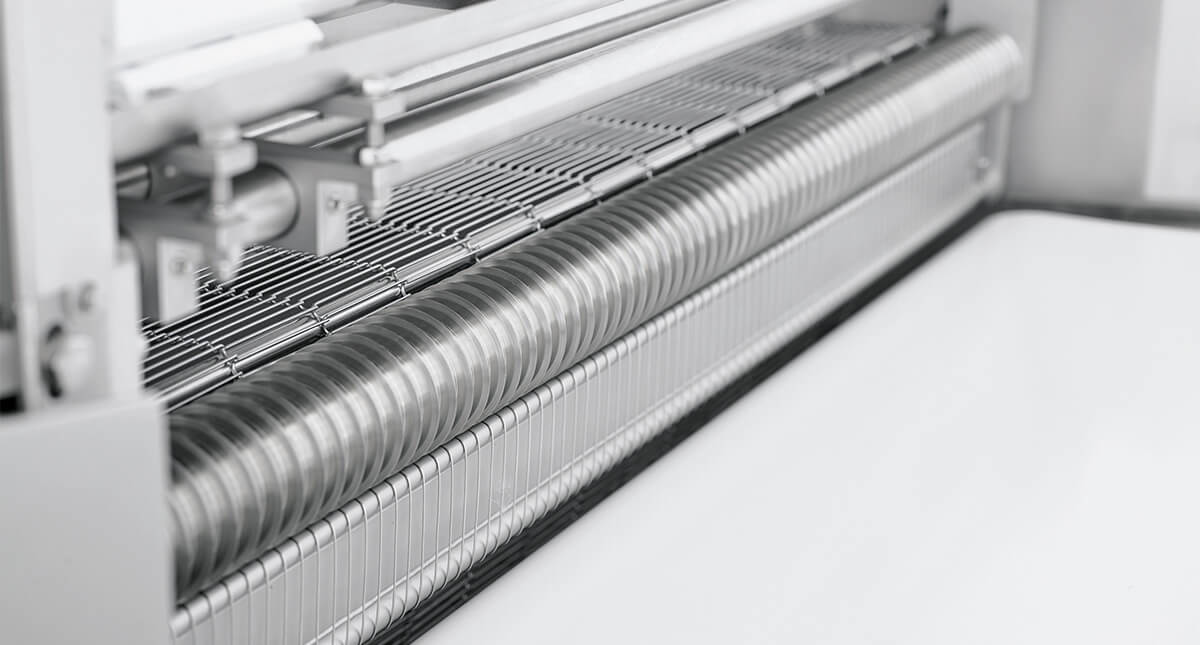

- hygienic design with stainless steel surfaces for maximum cleanliness and ease of cleaning

- integral patented TURBOTEMPER® with a tempering capacity of 800 to 1100 kg/h at processing temperatures up to 2ºC higher than those in the conventional tempering process

- machine widths of between 820 and 1300 mm

- up to 400 kg of chocolate processed per hour

- blower operating within a tolerance of only ± 1% over the entire width of the machine

- specially developed stored program control system for maximum ease of operation; industrial PC with color display

- bottoming: uniform bottom bath through patented bottom roller and additionally new with adjustable bottom bath length

- detailer: in a new sanitary design, without any straps, easily removable for cleaning and maintenance

- low energy demand by efficient technology using energy saving components (e.g. IE3 motors)

Additional equipment

As well as the option to extend the enrobing line by the addition of a THERMO FLOW® cooling tunnel, a comprehensive range of extra equipment is available:

- bottom coaters and pre-coating machines

- sprinkling devices operating from above or polydimensionally

- strip coating device

- pressure curtain device

- product hold down drum roller

- wire belt hold down device

- the DECORMATIC® automatic decorating system, DC5 decorating rollers

- biscuit turn-over device

- product depositor and removal device

- truffle depositors

- truffle powdering and spiking stations

- cluster formers

- forming and extruding systems for pralines and bars

- chocolate tanks and pumps

Product Brochure

Sollich-Temperstatic-T6.pdf