Thermo-Flow® + type KSK

The Type KSK Thermo-Flow® plus cooling tunnel is the high-performance cooling tunnel for chocolate coatings in the SOLLICH range. The combination of radiation and convection cooling from above and cold water contact cooling from beneath enables optimum quality to be achieved in the shortest possible cooling times. The cooling tunnels are designed as a modular system and consist of sections 3 m in length. Because of their precision fit, the polyurethane hoods are airtight without the need for a seal. Energy-saving CFC-free insulation is of course a standard feature, and the equipment naturally complies with GMP guidelines.

The cooling principle

The high-performance cooling tunnel for chocolate coatings operates with a combination of radiation and convection cooling from above and cold water contact cooling from below.

Fields of application

Because of their combination of cooling principles,Type KSK Thermo-Flow® plus cooling tunnels are suitable for cooling chocolate coatings in high-output production lines.

SOLLICH Thermo-Flow® plus cooling tunnels are available with belt widths from 320 mm to 3000 mm and in lengths of up to 100 m.

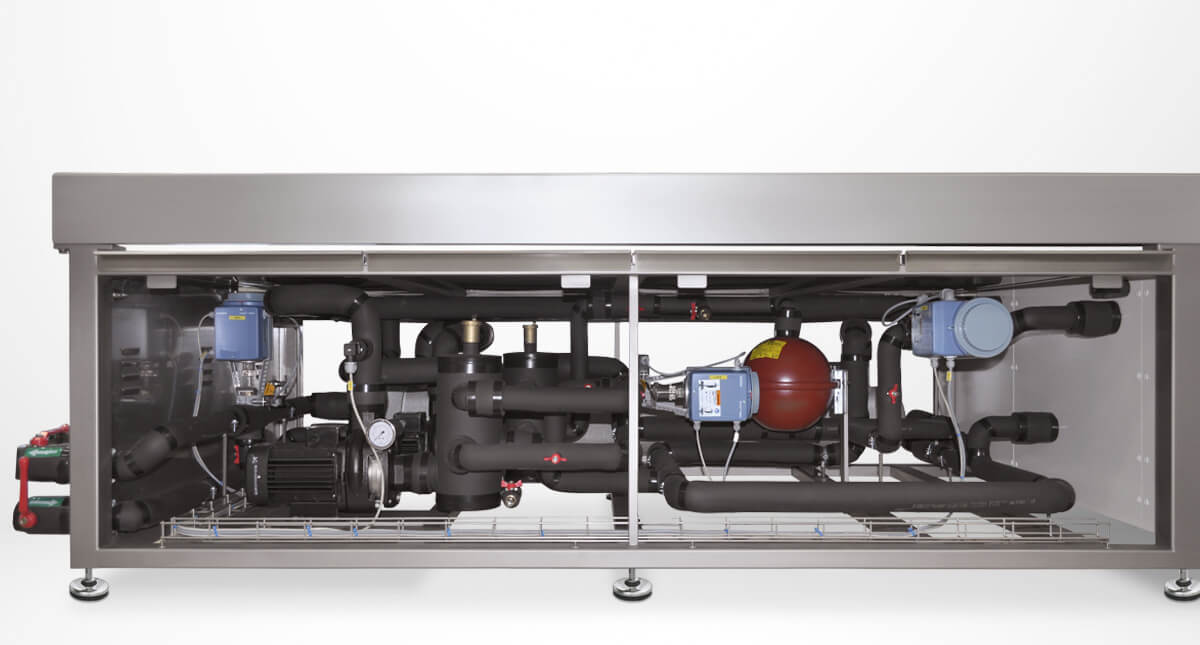

Patented temperature controls

Unfortunately, if production is interrupted the result in practical terms is often a change of temperature in the cooling tunnel. If required, Type KSK cooling tunnels may be fitted with a new patented temperature control device which ensures that the temperatures at the tunnel entrance and exit always remain constant, irrespective of the volume of products passing through the tunnel.

In the commissioning phase, or if production is interrupted, temperature conditions in the cooling tunnel are automatically adjusted so that the coating always sets under optimum physical conditions. The result is consistently good gloss and a long shelf life for the coating. The formation of unstable beta crystals as a result of poor cooling practice is prevented.