BCW-ECO

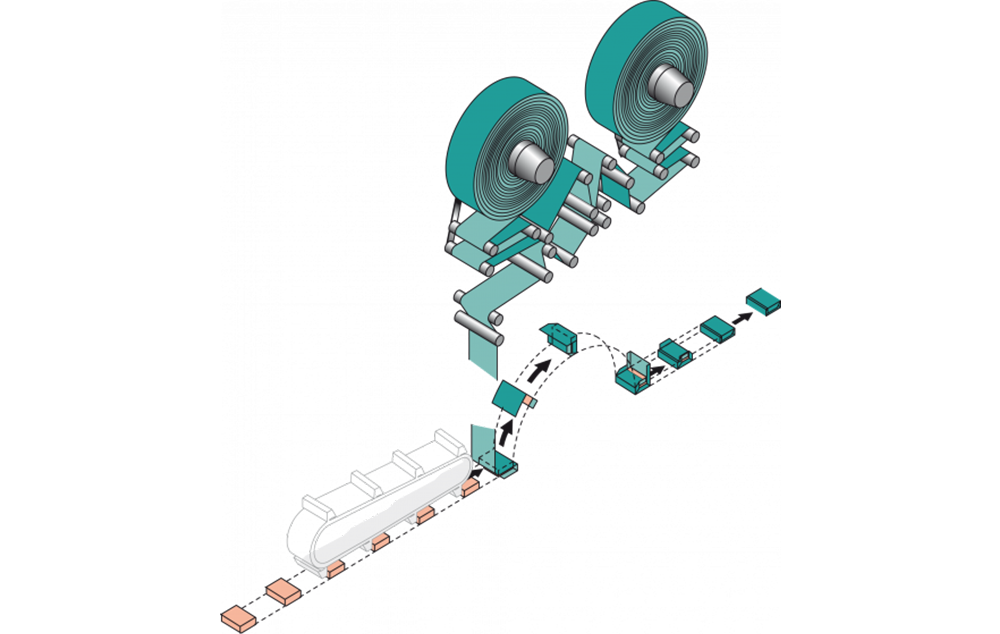

Wrapping machine for preformed bouillon tablets.

Compact and efficient overall system thanks to direct connection between product press and packaging machine.

Product Characteristics

Folding type

- Side Fold

Products

- Preformed Tablets

Product dimensions

- Length: 28 – 32 mm

- Width: 22 – 25 mm

- Height: 8 – 11 mm

- Special sizes upon request

Output

- Up to 750 products/min

Technical Data

Utilities

Connected load:

- Mechanical separation 16 kVA

Compressed air consumption:

- 1,5 m³/h; 600 kPa

Cooling water consumption:

- 0,15 m³/ h

Temperature: 10 … 15°C

Pressure: min. 200 kPa

Measurements

Machine:

- Length: 3000 mm

- Width: 1200 mm

- Height: 2300 mm

Switch cabinet:

- Length: 2000 mm

- Width: 500 mm

- Height: 1900 mm

Weight

- Machine: 2100 kg

- Switch cabinet: 550 kg

Wrapping material

- heat-sealable plastic monofilm

- special materials upon request

Material dimensions

- Reel diameter: Up to 350 mm

- Core diameter: 70 – 76,2 mm

Equipment & Options

Special features

- Transfer of the properly aligned product flow from the press and direct feeding to the BCW-eco

- Space-saving design by eliminating synchronization and separation of the product flow prior to the packaging process

- Automatic splicer to change wrapping material reels without stopping the machine

- Pneumatic core locking and reel tensioning devices

- Servo-driven wrapping material feed rollers and wrapping material knife

- photo-electric print mark registration to control the wrapping material feeding system for the positioning of the sealing mask and print image in always same position for each wrapped product

- Device for heat sealing of the wrapping material fold

- Ejection of spliced, unwrapped and products with mal-registered print image

- Servo control with PLC functions

- Central lubrication of all gear parts including pressure control

- All electrical and electronic components are located in a separate switch cabinet

- Excellent accessibility for operation, maintenance and cleaning purposes

- Easy operation due to the touch screen

- Due to the automatic operation, several machines can be handled by one operator

Combinations

- Direct synchronisation with the cube press.

Optional extras

- Turning device at 180° for tablets

- Code-dating device (upon request)

- Insertion of a tearing aid into the packaging material

- Detection system for manufacturer foil splices of the wrapping material (splice adhesive tapes) and ejection of the corresponding products

- automatic wrapping material web tracking control to center the wrapping material feed in direction of travel

- Equipment package for easy visual inspection and preventive maintenance

Product Brochure

BCW-eco_ENG_20_1_web.pdf