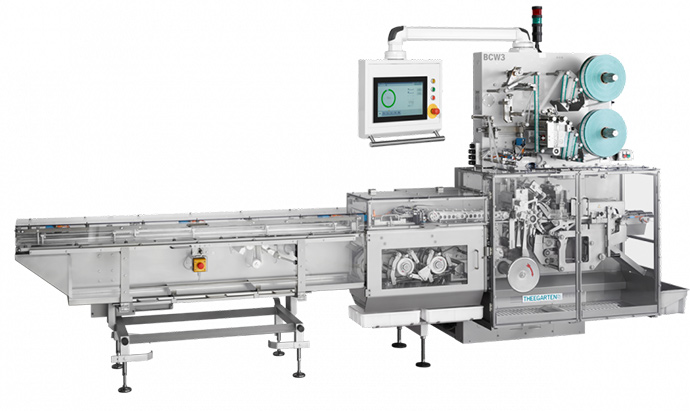

BCW3

High speed wrapping machine for preformed bouillon cubes and tablets. Very high output rates for mass production are achieved by simultaneous feeding and wrapping in twin-lane execution.

Product Characteristics

Folding type

- Envelope Fold

- Bottom Fold

- Side Fold

Products

- Preformed Cubes

- Preformed Tablets

Product dimensions

- Length: 13,5 – 35 mm

- Width: 13,5 – 25 mm

- Height: 6 – 20 mm

- Special sizes upon request

Output

- Up to 1700 products/min (preformed cubes)

- Up to 1400 products/min (preformed tablets)

Technical Data

Utilities

Connected load:

- Mechanical separation 16 kVA

- Electronic separation 25 kVA

Compressed air consumption:

- 1,5 m³/h; 600 kPa

Measurements

Machine:

- Length: 4300 mm

- Width: 1200 mm

- Height: 2300 mm

Switch cabinet:

- Length: 2000 mm

- Width: 500 mm

- Height: 1900 mm

Weight

- Machine: 2000 kg

- Electronic separation: 400 kg

- Switch cabinet: 400 kg

Wrapping material

- Aluminium/paper – coated (sealable)

- Aluminium/OPP – coated (sealable)

- Metallized OPP upon request

Material dimensions

- Reel diameter: Up to 350 mm

- Core diameter: 70 – 76,2 mm

Equipment & Options

Special features

- Automatic splicer to change wrapping material reels without stopping the machine

- Pneumatic core locking and reel tensioning devices

- Servo-driven wrapping material feed rollers and wrapping material knife

- Ejection of spliced, mal-registered and unwrapped products

- Servo control with PLC functions

- Central lubrication of all gear parts including oil pressure control/temperature control

- All electrical and electronic components are located in a separate switch cabinet

- Excellent accessibility for operation, maintenance and cleaning purposes

- Direct synchronisation with the cube press

- Sealing device with optional cooling section for wrapped products

- Easy operation due to the touch screen

- Due to the automatic operation, several machines can be handled by one operator

Combinations

- Direct synchronisation with the cube press.

Optional extras

- Photo-electric print registration

- Turning device at 180°

- Code-dating device

- Tear tape device

- System zur Einbringung eines Aufreißfadens

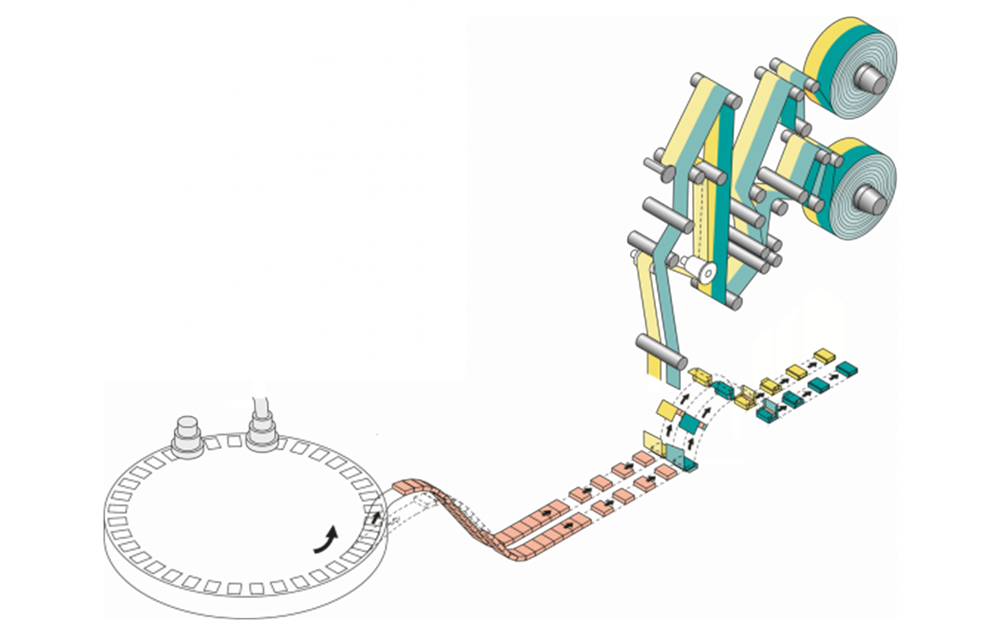

Electronic separation

- For the simultaneous wrapping of 2 resp. 4 square resp. rectangular products, consisting of one accumulation conveyor and two parallel arranged phasing and acceleration conveyors for the controlled product positioning

Mechanical separation

- For the simultaneous wrapping of 2 resp. 4 cubes, consisting of two transport conveyors with a length of 1 meter each and two 90° infeed curves

Product Brochure

BCW3_ENG_19_1_web.pdf