BLM

The first cartoning system that can keep up with the high-performance machines from Theegarten-Pactec. The cartoner is specially designed for direct connection to primary packaging machines with high output. The modular design offers high flexibility for product formations within the carton.

Product Characteristics

Folding type

Display Carton

- Single-row

- Multi-row

- Multi-layer

- Upright

Products

- primary wrapped products e.g. chocolate bars, cereals, stock cubes, soft caramels

Product dimensions

- Length: min. 75 mm

- Width: max. 250 mm

- Height: max. 120 mm

Output

- Up to 2000 individual products/min

- Up to 120 display cartons/min

Technical Data

Measurements

- Length: 3700 – 7000 mm

- Width: 1900 mm

carton feeding 3700 mm

- Height: 1600 mm

carton feeding 1900 mm

Weight

- 4500 – 7000 kg

Wrapping material

- Carton blank

Material dimensions

- Length Carton blank: 120 – 700 mm

- Width: no limitations

Equipment & Options

Special features

- Cartoning system for products primary wrapped in fold wrap or flow pack

- Modular system for different product sizes, output ranges, packing formations, and box designs

- Simultaneous erecting, filling and closing of several cartons enables maximum performance

- Balcony design – drive and working / operation section strictly separated

- Complete operation from front side – a mirrored version of the cartoner is available to match the operating side of the connected primary packaging machine

- Transparent machine cover for easy visual inspection and preventive maintenance

- Excellent accessibility for operation, maintenance and cleaning purposes

- Operator touch panel for intuitive user interface

- Due to the automatic operation, several machines can be handled by one operator

- System of protection: IP 54

Combinations

- The cartoning system is designed for direct connection to a high-performance primary wrapping machine in order to package high output quantities reliably and efficiently into cartons.

Optional extras

- Integration of coding device for best before date or batch number

- Tool-less format change

- Remote assistance via network connection

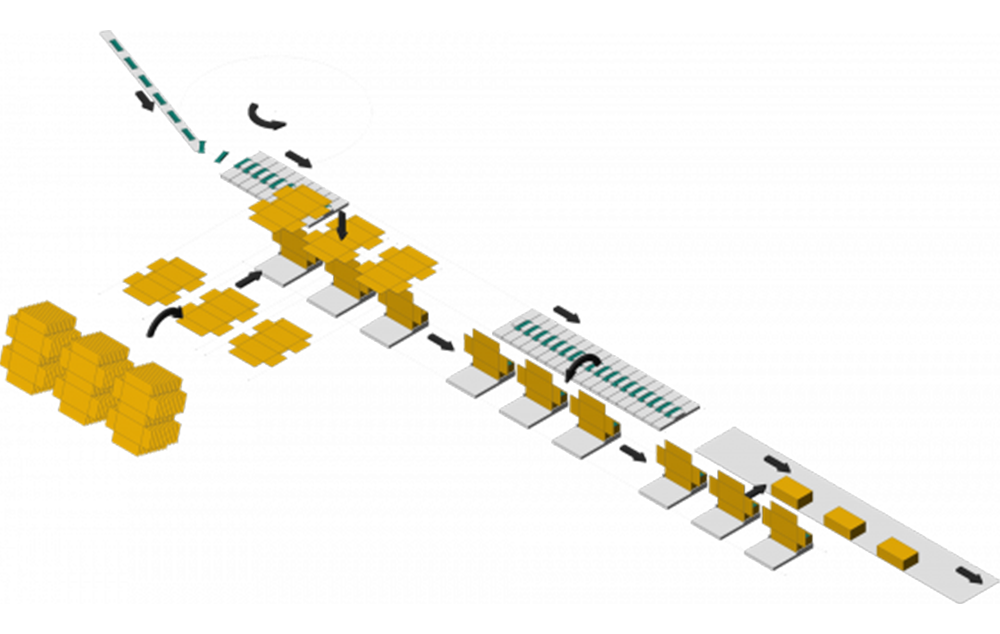

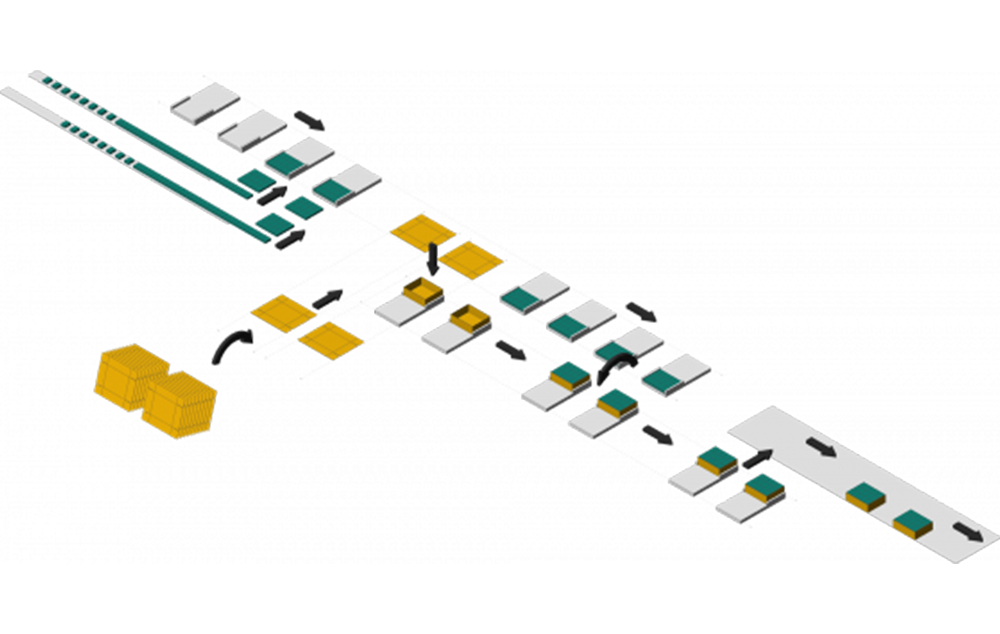

Product feeding and grouping

- Feeding and grouping device individually adapted to the wrapped product for optimal connection of the cartoner to the primary packaging machine

- Incomplete product groups are rejected before entering the secondary packaging process

Carton feeding and carton erector

- Easily accessible carton blanks magazine

- „No carton blank – no glue“ functionality

- Carton erector with suction device for precise positioning of the carton

Carton filling and closing

- One machine enables cartons with single-row, multi-row, multi-layer and upright arrangement of the products

- Robotic transfer tool for product pick up and correct positioning in the box

- Vacuum monitoring at the suction device minimizes loading defects and allows a controlled reject of non – properly filled boxes

- Robot transfer of the filled boxes to the discharge conveyor

Product Brochure

BLM_ENG_20_1_web.pdf