CFW-S

Wrapping machine for chocolate bars and similar products in letter fold with or without banderole. The particularly gentle processing of the products enables high-speed packaging.

Product Characteristics

Folding type

- Envelope Fold

- Envelope Fold with Banderole

Products

- Moulded Chocolate Products

- Enrobed Chocolate Products

- Wafers

Product dimensions

Length: 25 – 150 mm

Width: 15 – 50 mm

Height: 5 – 25 mm

Output

- Up to 800 products/min

Technical Data

Utilities

- Connected load: 22 kVA

- Compressed air consumption: 1,5 m³/ h; 600 kPa

- Cooling water consumption:

0,15 m³/ h

Temperature: 10 … 15°C

Pressure: min. 200 kPa

Measurements

Machine:

- Length: 5200 mm

- Width: 1350 mm

- Height: 2490 mm

Switch cabinet:

- Length: 1800 mm

- Width: 500 mm

- Height: 2100 mm

Weight

- Machine: 3100 kg

- Switch cabinet: 550 kg

Wrapping material

- Aluminium foil

- Aluminium laminates

- Polypropylene

- Paper (Banderole)

Material dimensions

- Reel diameter: up to 350 mm

- Core diameter: 70 – 76,2 mm

Equipment & Options

Special features

- Electronically controlled product feed

- A continuous transport of the products is achieved by precisely synchronised conveying speeds of the feeding conveyors. This guarantees that delicate products are almost not exposed to any accumulation pressure.

- A particularly gentle handling of the products is guaranteed by overlapping conveyor stages – no roller edges between the conveyor stages

- Water-cooled feeding components to avoid product damages

- Tool-less quick-change systems for feeding and folding components for quick cleaning, maintenance and format changeover

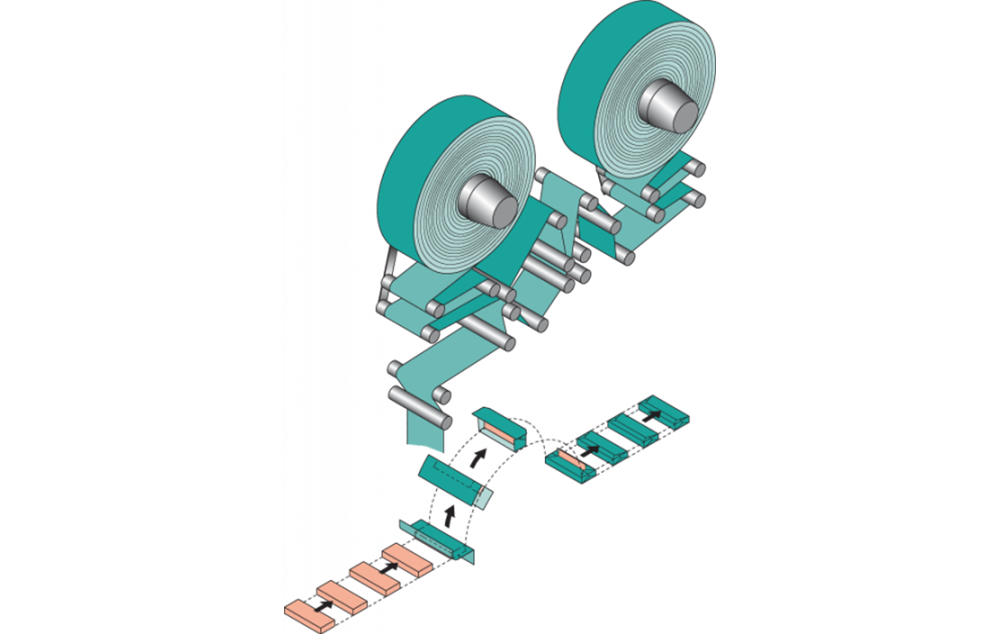

- Most gentle product handling by active carrying of the products from the lug belt to the wrapping section

- Spring retainer jaws within the packing head compensate product tolerances

- Automatic splicer to change wrapping material reels without stopping the machine

- Ejection of spliced, mal-registered and unwrapped products

- Pneumatic core locking and reel tensioning devices

- Servo-driven wrapping material feed rollers and wrapping material knife

- Air support to stabilising the packaging material

- Servo control with PLC functions

- Central lubrication of all gear parts including oil pressure control

- All electrical and electronic components are located in a separate switch cabinet

- Quick-change systems for the packaging knife for quick cleaning and maintenance

- Excellent accessibility for operation, maintenance and cleaning purposes

- Easy operation due to the touch screen

- Due to the automatic operation, several machines can be handled by one operator

Combinations

Instead of a direct synchronization to the production line the machine can also be supplied with separate feeding systems, for instance if the bars are provided on feeding plates. A synchronization with down-stream overwrapping machines (cartoning or flow-pack) is also possible.

Optional extras

- Photo-electric print mark registration to control the wrapping material feeding system for the positioning of the print image in always same position on each wrapped product

- Detection system for manufacturer foil splices of the wrapping material (splice adhesive tapes) and ejection of the corresponding products

- automatic wrapping material web tracking control to center the wrapping material feed in direction of travel

- Additional reel holders for a second wrapping material (banderole or under strip) with automatic splicer

- Special paper feeding device for the application of two separate wrapping materials (i. e. cellophane or PP films and aluminium/paper-coated) glued together on the machine by means of a gluing device

- Gluing device for the application of one or two glue dots for product closure

- Device for heat sealing of the wrapping material fold

- 180° turning device at the discharge to orientate the products according to the request of the secondary wrapping process

Product Brochure

CFW-S_ENG_19_1_web.pdf