CWM2

Compact and flexible wrapping machine for chocolate products. The modular design enables the processing of different products and wrapping styles on one machine.

Product Characteristics

Folding type

- Double Twist

- Top Twist

- Side Twist

- Envelope Fold

- Bunch

Products

- Deposited Chocolate Products

- Enrobed Chocolate Products (wafers, biscuits, cereals)

Product dimensions

Double Twist and Bunch

- Length: 16 – 60 mm

- Width: 15 – 40 mm

- Height: 8 – 28 mm

Top Twist

- Length: 20 – 28 mm

- Width: 18 – 28 mm

- Height: 15 – 28 mm

Side Twist

- Length: 18 – 40 mm

- Width: 15 – 35 mm

- Height: 8 – 30 mm

Envelope Fold

- Length: 18 – 60 mm / 18 – 40 mm (controlled discharge)

- Width: 15 – 40 mm

- Height: 8 – 28 mm

Double Twist und Bunch

- Ø 18 – 35 mm

- Height: 8 – 28 mm

Top Twist

- Ø 22 – 35 mm

- Height: 15 – 28 mm

Side Twist

- Ø 18 – 35 mm

- Height: 8 – 30 mm

Double Twist and Foil Wrap

- Ø 18 – 35 mm

Output

- Up to 600 products/ min Double Twist, Bunch and Envelope Fold

- Up to 450 products / min Protected Twist

- Up to 350 products / min Top Twist, Side Twist and Foil Wrap

Technical Data

Utilities

- Connected load: 11 kVA

- Compressed air consumption: 1 m³/h; 600 kPa

Measurements

- Length: 3650 mm

- Width: 1900 mm

- Height: 1960 mm

Weight

- 2200 kg

Wrapping material

- Wax paper

- Cellophane

- Polypropylene

- Aluminium foil

Material dimensions

- Reel diameter: up to 350 mm

- Reel width: up to 150 mm

- Core diameter: 70 – 79 mm

Equipment & Options

Special features

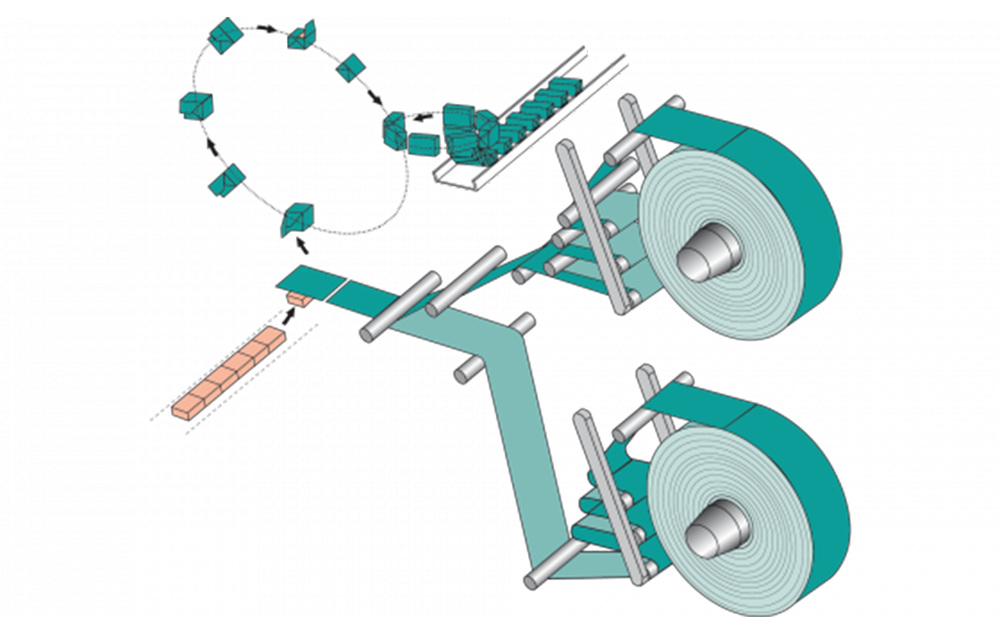

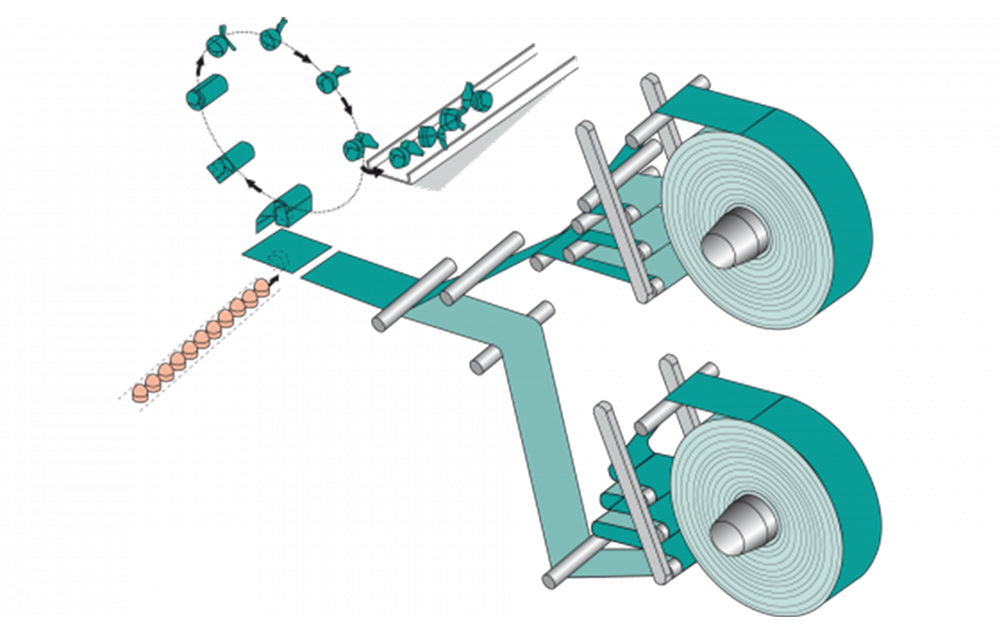

- Electronically controlled, servo driven infeed module for single lane product accumulation and synchronization

- Accumulation belt to accumulate the products

- Vacuum supported phasing belt to synchronize the products to the machine cycle

- Inline transfer of the products to the pickup position

- Feeding system controlled by laser sensors to adopt machine speed to the product accumulation level

- Two reel holders for the wrapping material with mechanical core locking devices

- Servo motor driven wrapping material reels

- Servo motor driven wrapping material draw off roller to control cut off length and adopt photoelectrical print registration signals

- Servo motor driven wrapping material knife with carbon steel insert for a precise cut and an extended service life

- Automatic splicer to change wrapping material reels without stopping the machine

- Saving of wrapping material by »no product – no paper« -device

- Discharge chute for wrapped products

- Ejection of spliced, mal-registered and unwrapped products

Combinations

- Beside manual feeding, the machine can be directly synchronized to the production line by means of a Theegarten-Pactec belt feeding or robotic pick and place system.

Optional extras

- Modular machine design in order to facilitate the change of wrapping style and/or product dimensions

- Accordingly to the requirements of the products, the feeding system is designed as robotic system with lug chain or as belt feeding system

- Additional reel holders for a second wrapping material (under strip) with automatic splicer

- Wrapping material feed for inner and outer wrapping material with optional displacement of the inner wrapper to guarantee a high wrapping quality

- Pneumatic core locking and reel tensioning devices

- Photo-electric print registration

- Defined product discharge

- Glue applicator for tag glue product closure

- Remote diagnostics

Product Brochure

CWM2_ENG_20_1_web.pdf