Distribution Systems

Distribution systems improve system efficiency through a fully automated connection between the packaging and production processes.

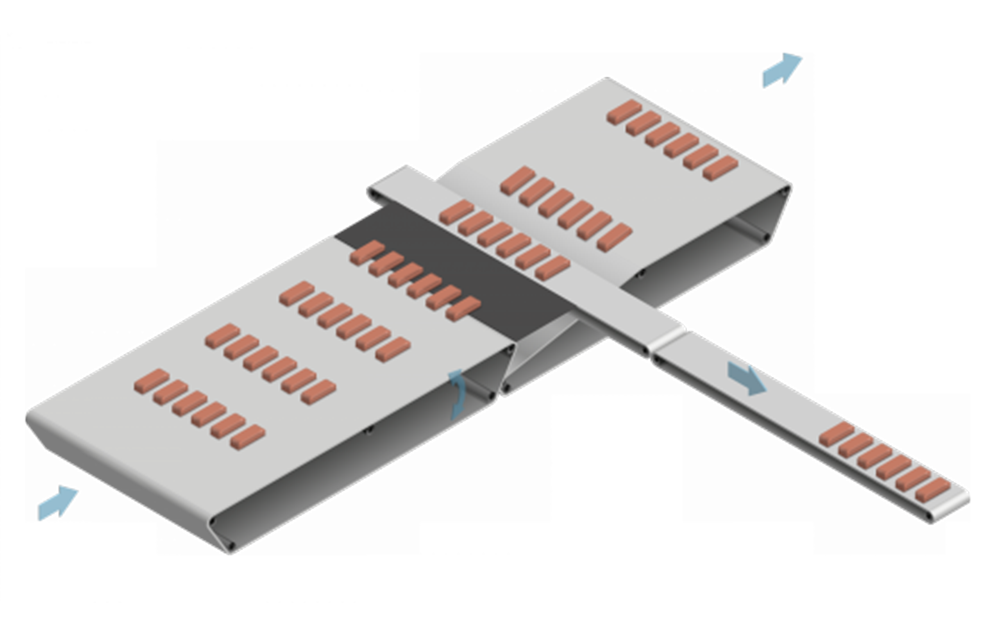

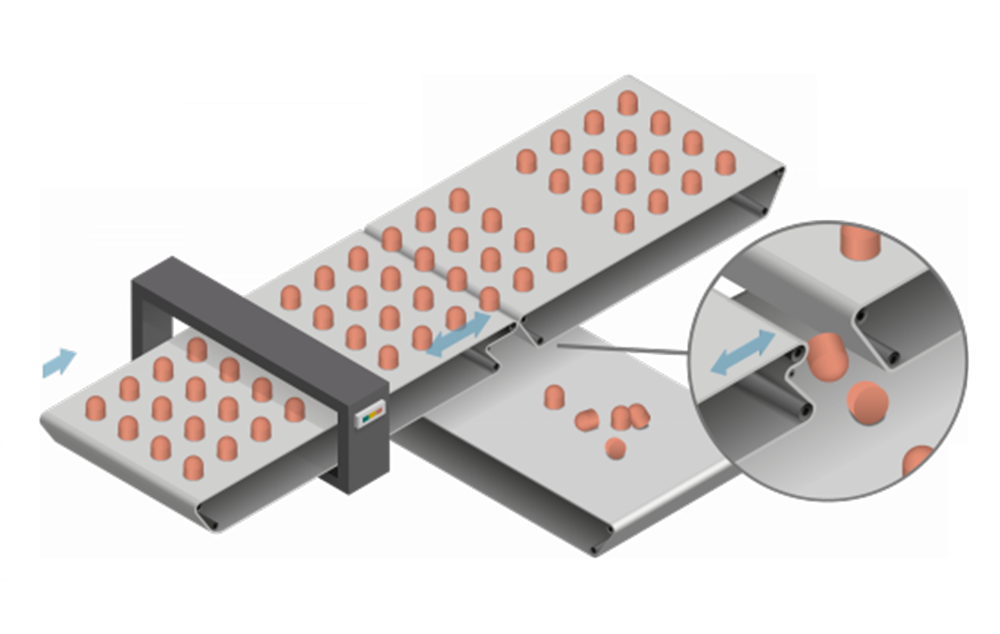

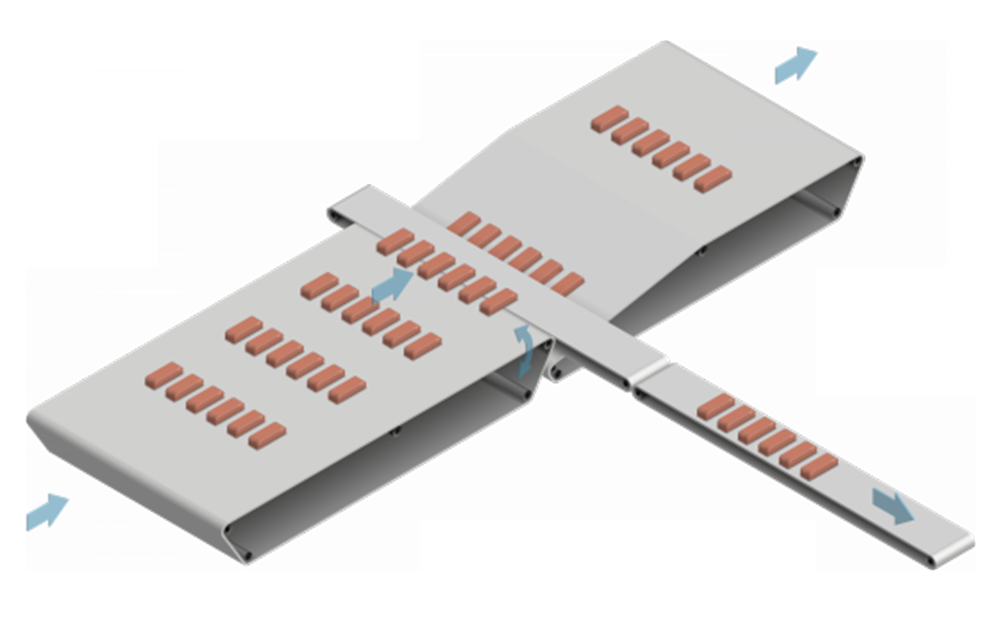

Cross Transfer Station with Pusher

- To transfer the product rows via an oscillating nose conveyor to a cross transfer conveyor respectively to the next transfer station in direction of the flow

- Transfer of products from the oscillating nose conveyor to a dead plate

- Transfer of products from the dead plate to the cross transfer conveyor by a pusher

- Three-phase motor driven conveyor, frequency controller integrated within the switch cabinet

- Servo-driven tilting function and pusher

- Pneumatic web tracking control

- Easy access for cleaning through removable conveyor support plates

- Quick tensioning devices for the conveyor belts for easy maintenance and service

- All product transfers and scrapers with underneath sliding waste trays

- Return shafts with diameter 10 mm for smooth product transfer

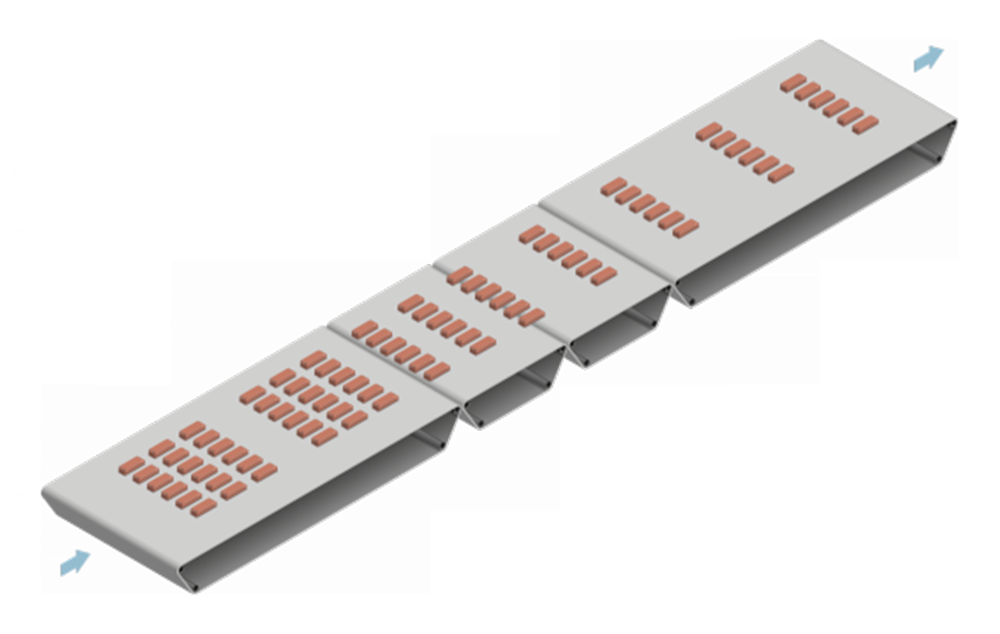

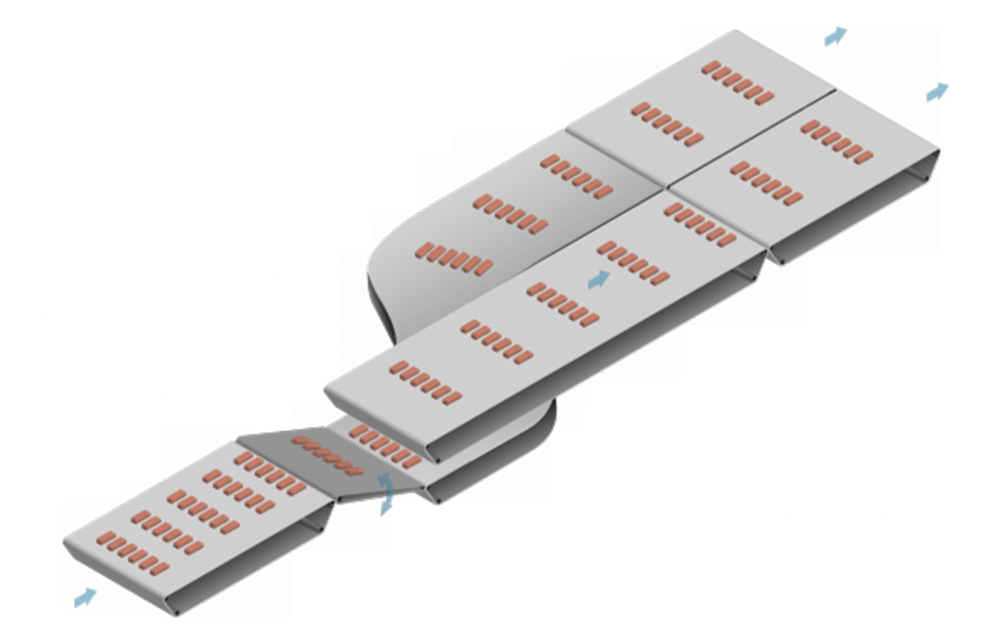

Phasing Conveyor

- Special conveyor to equalize the gaps between rows presented in mould configuration

- Reducing of gaps within the mould group structure

- Transfer of the products from an intermittent demoulding system to a continuously operating wrapping system

- Servo or AC motor driven

- Pneumatic web tracking control

- Easy access for cleaning through removable conveyor support plates

- Quick tensioning devices for the conveyor belts for easy maintenance and service

- All product transfers and scrapers with underneath sliding waste trays

- Return shafts with diameter 10 mm for smooth product transfer

- One- or two-stage design, depending on the functional requirements

Metal Detector

- Detection and rejection of metal contaminated product rows

- Integrated SAFELINE metal detector

- Integrated cross reject conveyor for the reject of contaminated products to one side and non-properly aligned products for wrapping to the other side

- Optional row aligner for alignment of the products at right angles to direction of product flow

- Three-phase motor driven conveyor, frequency controller integrated within the switch cabinet

- Pneumatic web tracking control

- Easy access for cleaning through removable conveyor support plates

- Quick tensioning devices for the conveyor belts for easy maintenance and service

- All product transfers and scrapers with underneath sliding waste trays

- Return shafts with diameter 10 mm for smooth product transfer

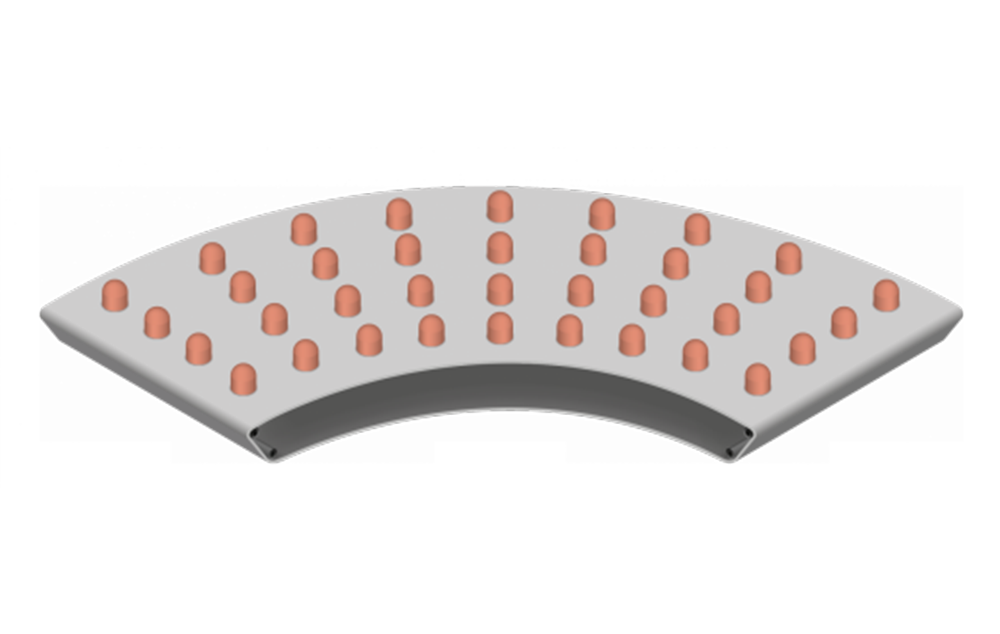

Curved Conveyor

- Curved feeding up to 180° at different widths and heights

- Transport of the products accordingly to layout requirements

- Transport of the products without destroying the row structure

- Three-phase motor driven conveyor, frequency controller integrated within the switch cabinet

- Easy access for cleaning through removable conveyor support plates

- Quick tensioning devices for the conveyor belts for easy maintenance and service

- All product transfers and scrapers with underneath sliding waste trays

- Return shafts with diameter 10 mm for smooth product transfer

- Flexible design of the inner radius

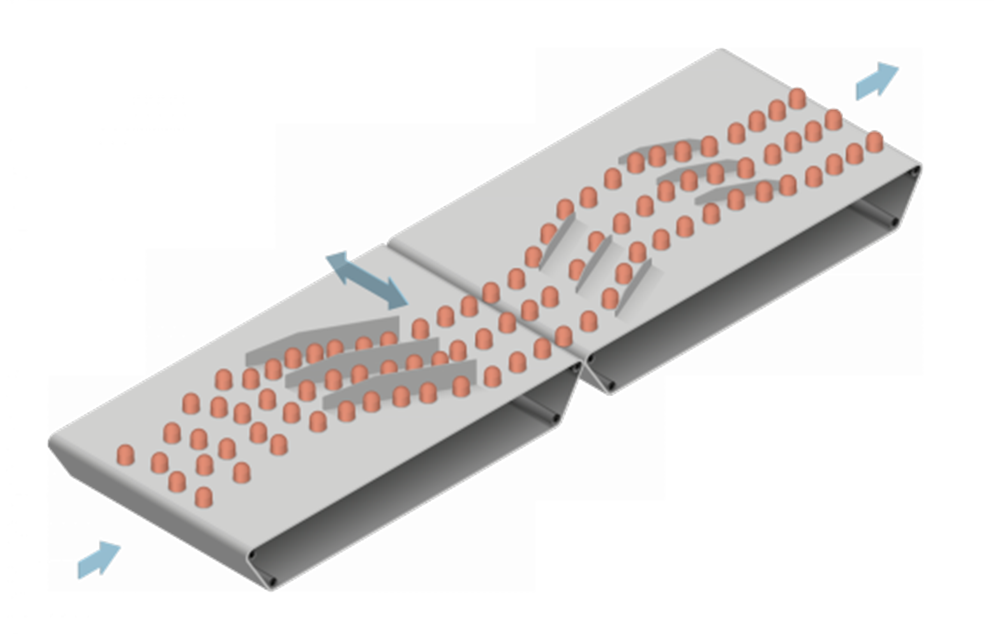

Lane Arrangement

- Continuous arrangement of lines in direction of product flow

- Fixed or swivelling guides convert the product presentation into the required numbers of product lanes

- Three-phase motor driven conveyor, frequency controller integrated within the switch cabinet

- Pneumatic web tracking control

- Easy access for cleaning through removable conveyor support plates

- Quick tensioning devices for the conveyor belts for easy maintenance and service

- All product transfers and scrapers with underneath sliding waste trays

- Return shafts with diameter 10 mm for smooth product transfer

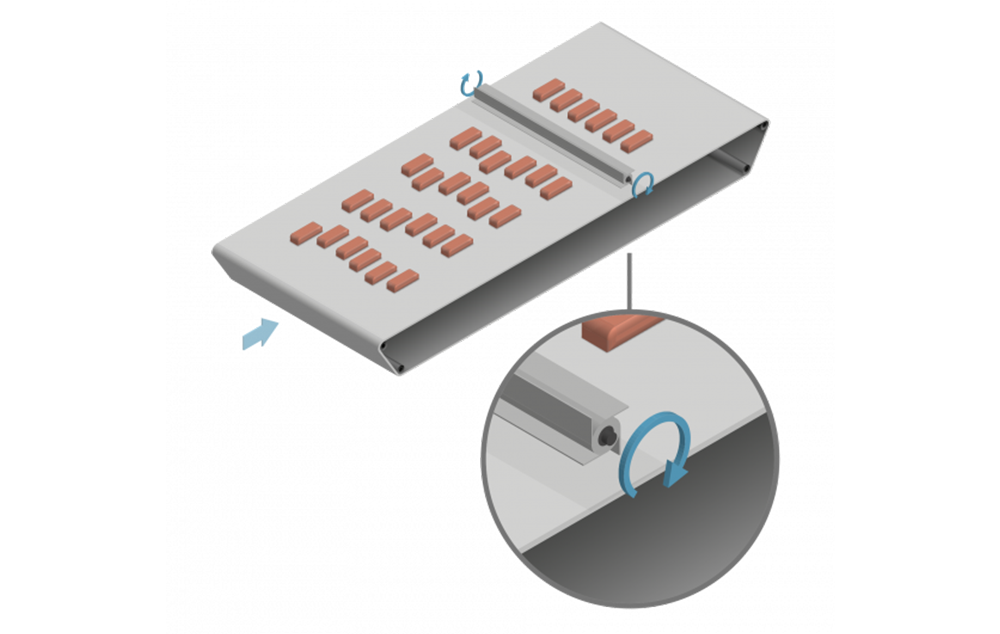

Row Aligner

- Alignment of the products at right angles to direction of product flow

- Row aligner operates pneumatically or servo motor driven

- Pneumatically – capacity up to 90 rows per minute

- Servo driven – capacity up to 120 rows per minute

- Easy access for cleaning through removable swivelling safety covers

- Three-phase motor driven conveyor, frequency controller integrated within the switch cabinet

- Pneumatic web tracking control

- Easy access for cleaning through removable conveyor support plates

- Quick tensioning devices for the conveyor belts for easy maintenance and service

- All product transfers and scrapers with underneath sliding waste trays

- Return shafts with diameter 10 mm for smooth product transfer

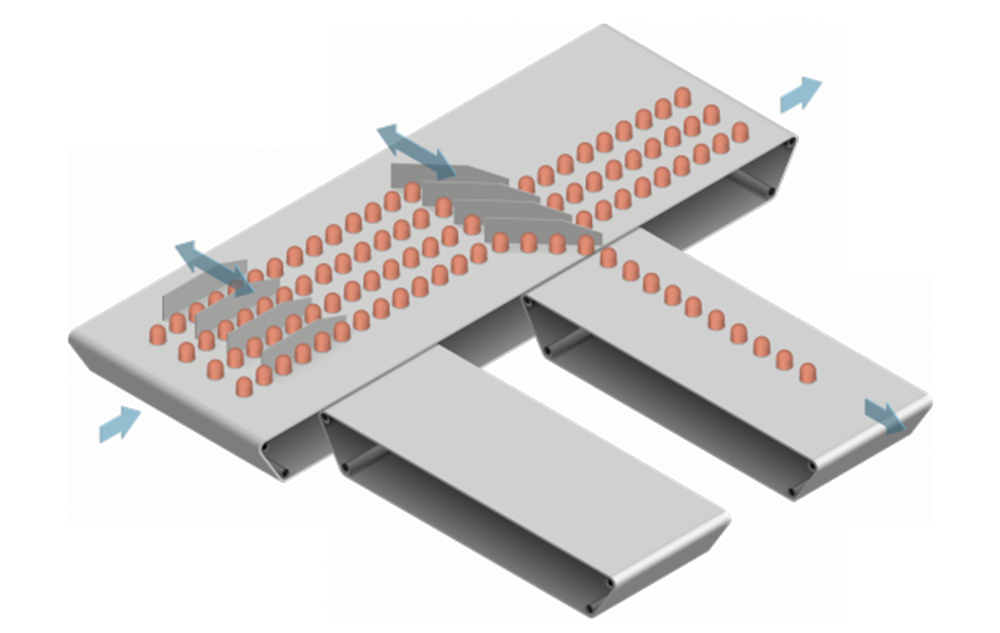

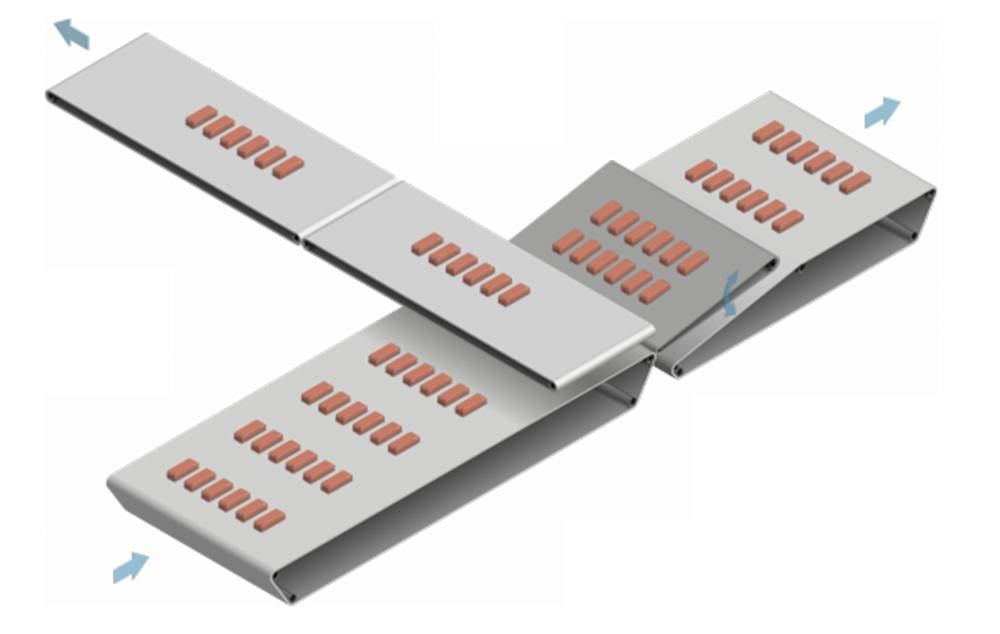

Pneumatic Product Guide

- Pneumatically driven line diverters for continuous cross transfer or shifting of product rows

- Product guides transfer the product lines to the feeding sections of the wrapping machines

- In case a wrapping machine is not ready for operation product rows pass on the main conveyor

- Three-phase motor driven conveyor, frequency controller integrated within the switch cabinet

- Pneumatic web tracking control

- Easy access for cleaning through removable conveyor support plates

- Quick tensioning devices for the conveyor belts for easy maintenance and service

- All product transfers and scrapers with underneath sliding waste trays

- Return shafts with diameter 10 mm for smooth product transfer

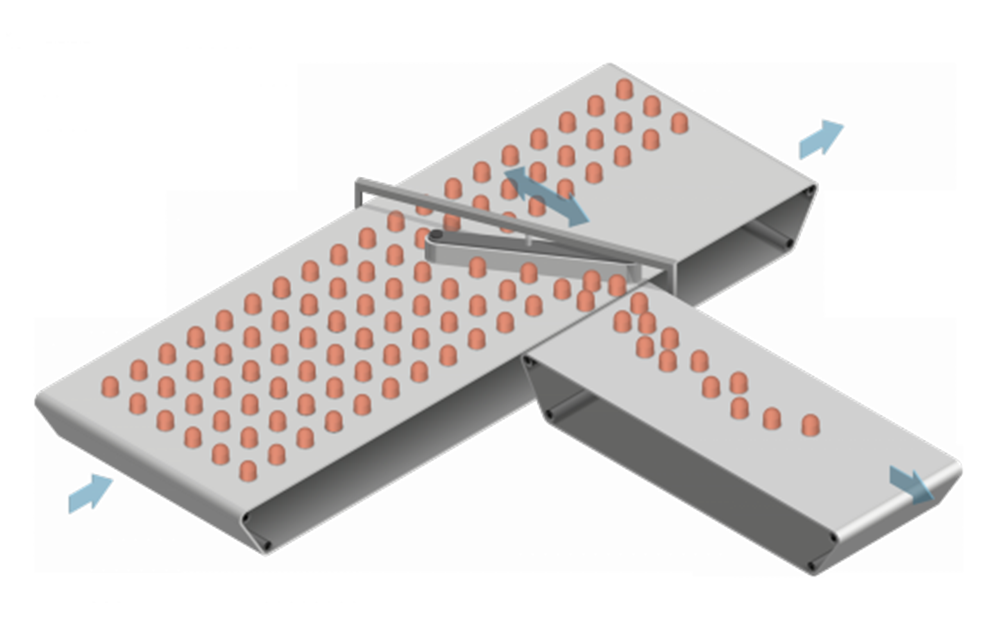

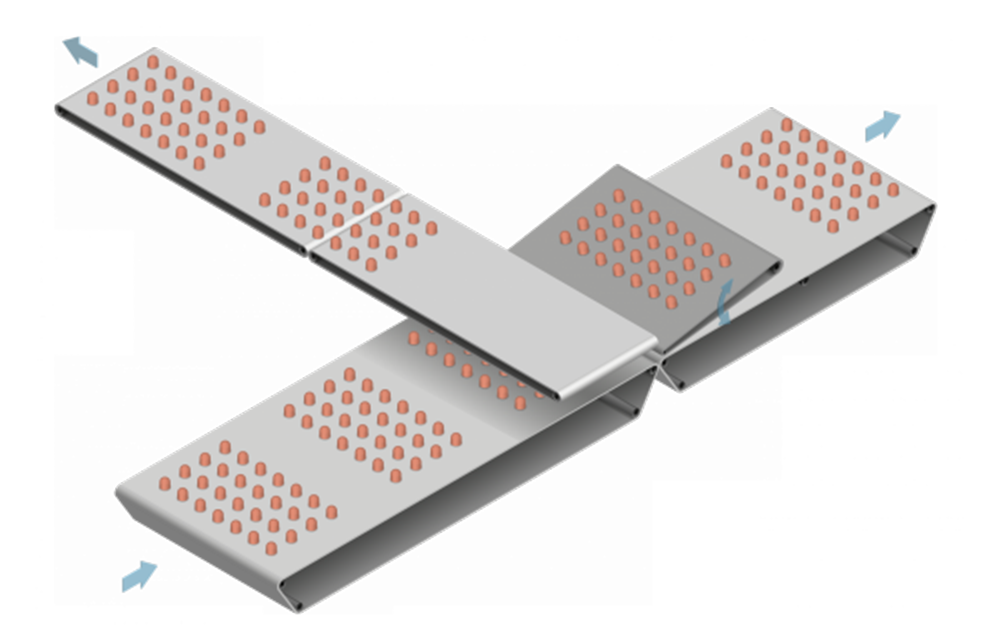

Linear Plough off device

- Moving plough off device for continuous cross transfer of product rows

- Transfer of product rows to the feeding section of the wrapping machine

- Quantity of transferred products is controlled by an adjustable plough off devices

- With driven product guide for most gentle product handling

- Three-phase motor driven conveyor, frequency controller integrated within the switch cabinet

- Pneumatic web tracking control

- Easy access for cleaning through removable conveyor support plates

- Quick tensioning devices for the conveyor belts for easy maintenance and service

- All product transfers and scrapers with underneath sliding waste trays

- Return shafts with diameter 10 mm for smooth product transfer

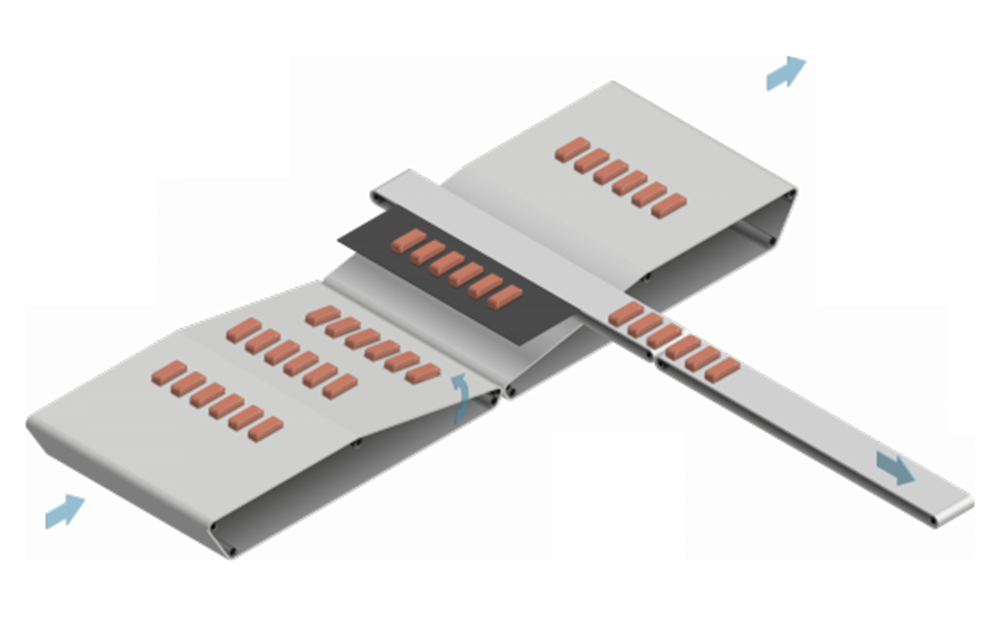

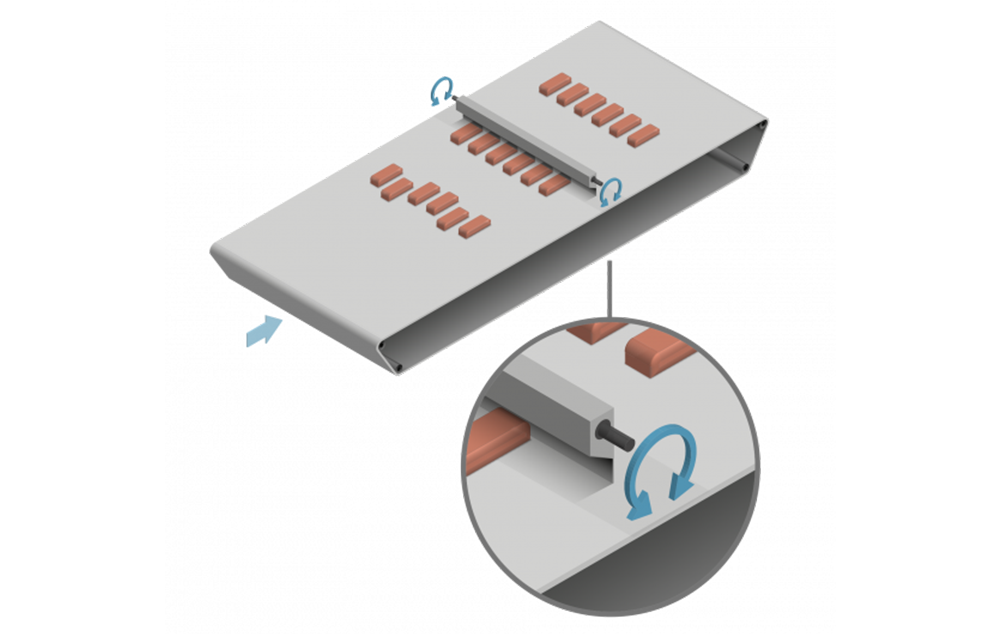

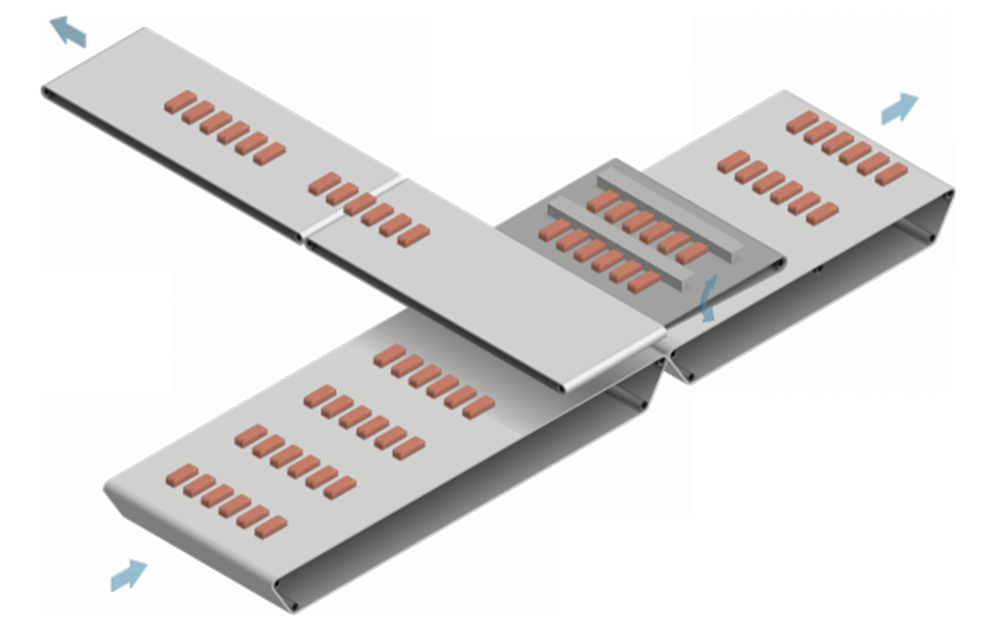

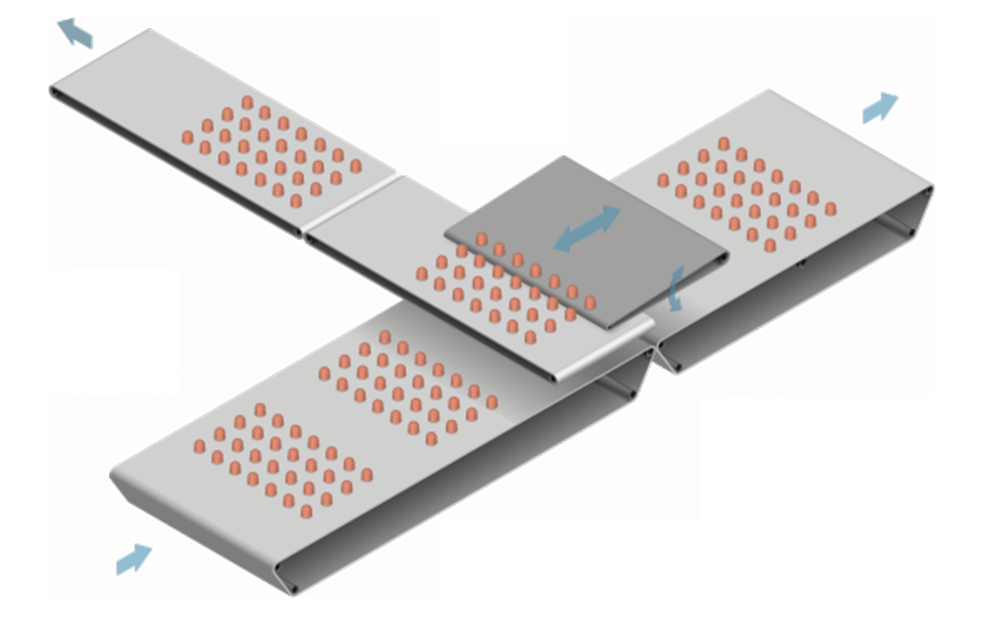

Cross Transfer Station

- To transfer the product rows via an oscillating nose conveyor to a cross transfer conveyor respectively to the next transfer station in direction of the flow

- Three-phase motor driven conveyor, frequency controller integrated within the switch cabinet

- Servo-driven tilting function

- Pneumatic web tracking control

- Easy access for cleaning through removable conveyor support plates

- Quick tensioning devices for the conveyor belts for easy maintenance and service

- All product transfers and scrapers with underneath sliding waste trays

- Return shafts with diameter 10 mm for smooth product transfer

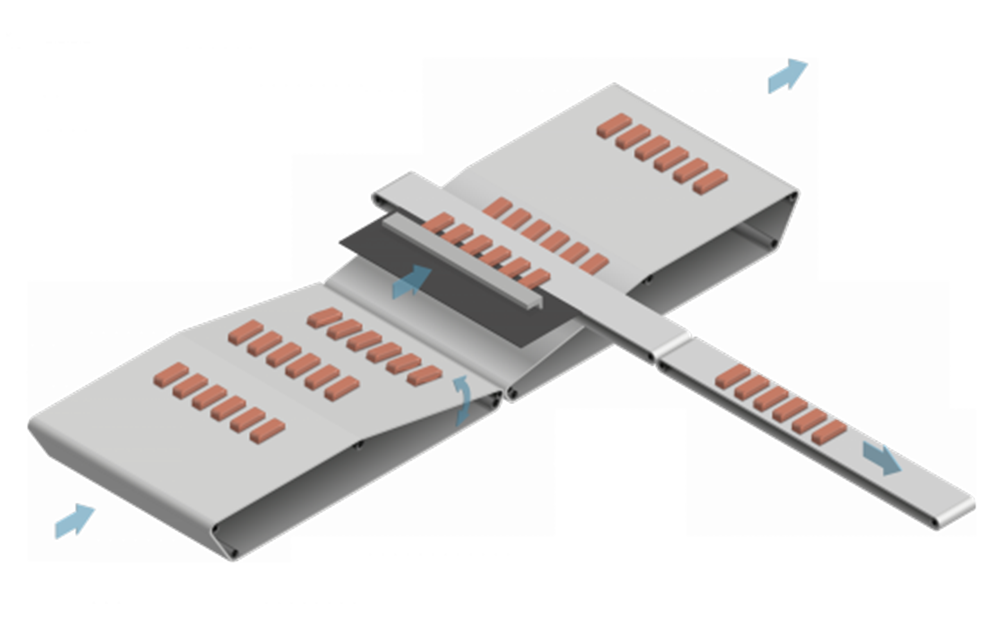

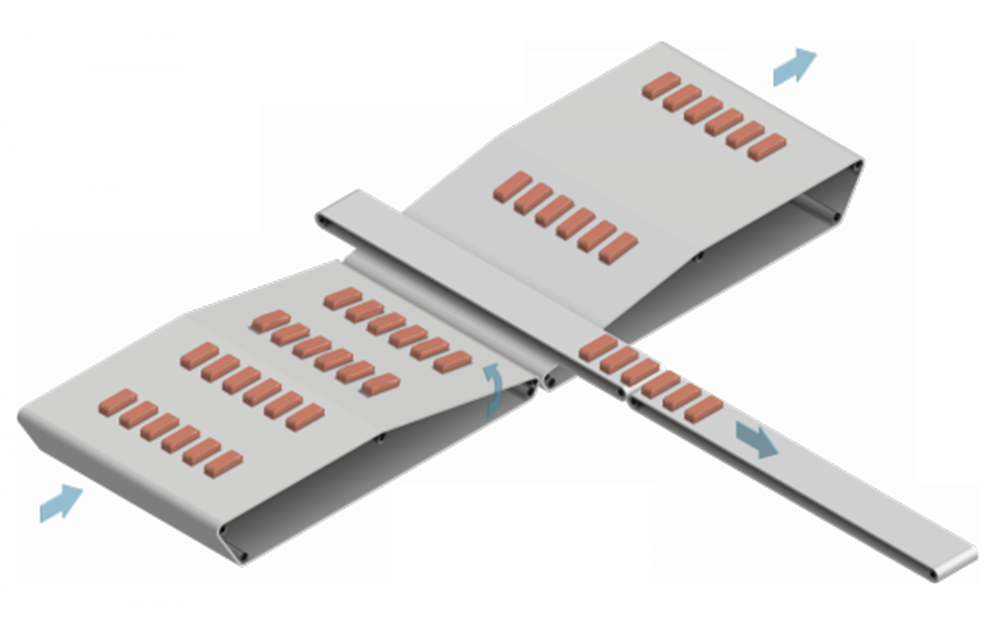

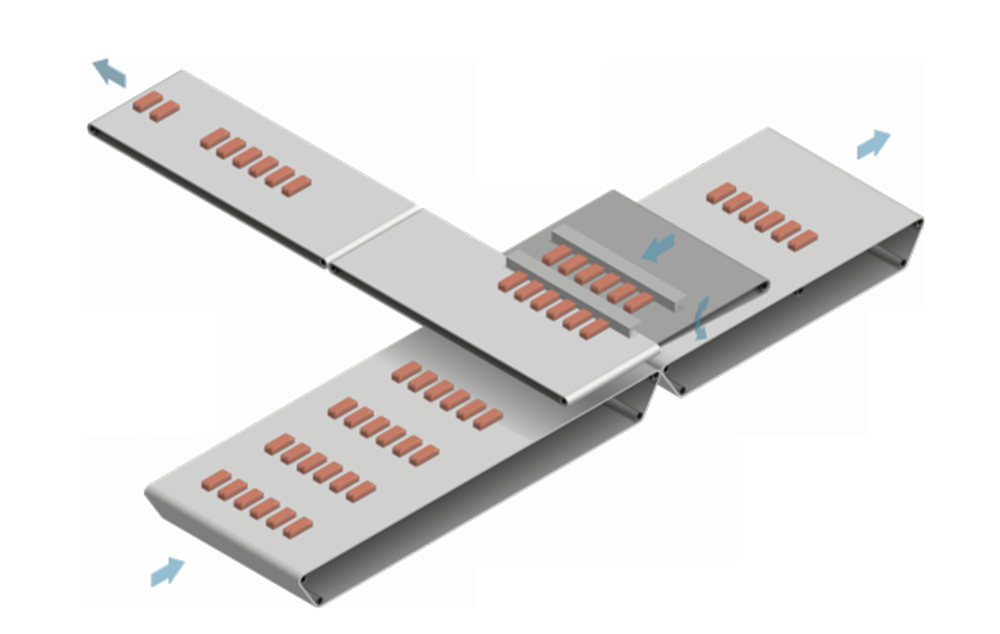

Cross Transfer Station F300

- To transfer products presented in mould configuration to a cross transfer conveyor respectively to the next transfer station in direction of the flow

- Oscillating and moveable product transfer conveyor

- The pull back function of the transfer conveyor places the products on the cross transfer conveyor

- Three-phase motor driven conveyor, frequency controller integrated within the switch cabinet

- Tilting function and moveable product transfer conveyor driven by two separate servo motors

- Pneumatic web tracking control

- Easy access for cleaning through removable conveyor support plates

- Quick tensioning devices for the conveyor belts for easy maintenance and service

- All product transfers and scrapers with underneath sliding waste trays

- Return shafts with diameter 10 mm for smooth product transfer

- Optional: Additional reversible conveyor stage to allow feeding from process and/or downstream storage system

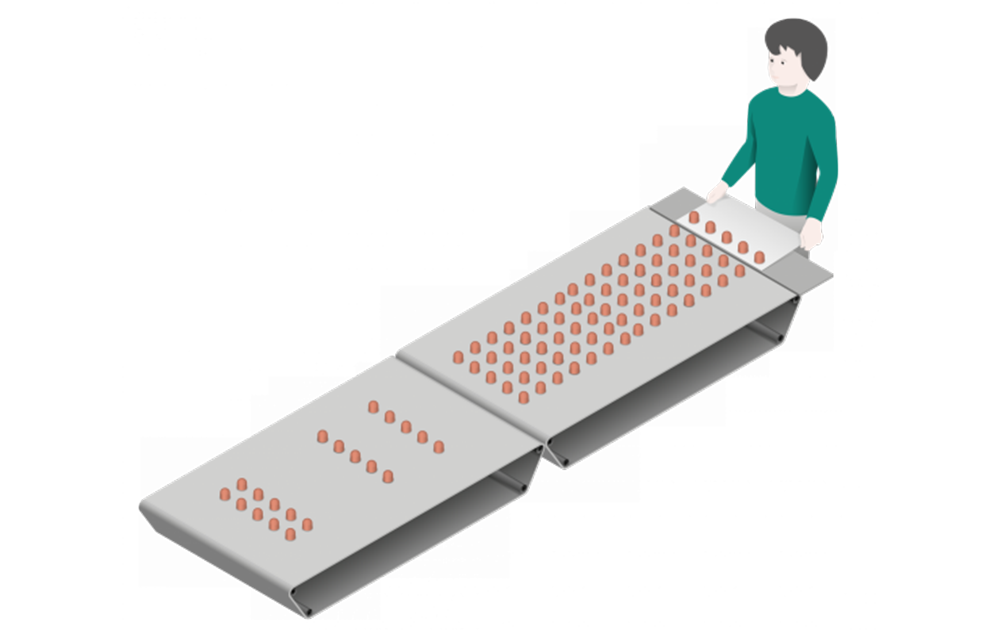

Overflow Conveyor

- Storage of product overflow not transferred to the wrapping machine

- Manual take off of product overflow

- Three-phase motor driven conveyor, frequency controller integrated within the switch cabinet

- Pneumatic web tracking control

- Easy access for cleaning through removable conveyor support plates

- Quick tensioning devices for the conveyor belts for easy maintenance and service

- All product transfers and scrapers with underneath sliding waste trays

- Return shafts with diameter 10 mm for smooth product transfer

- Food-operated switch for the conveyor when removing the products

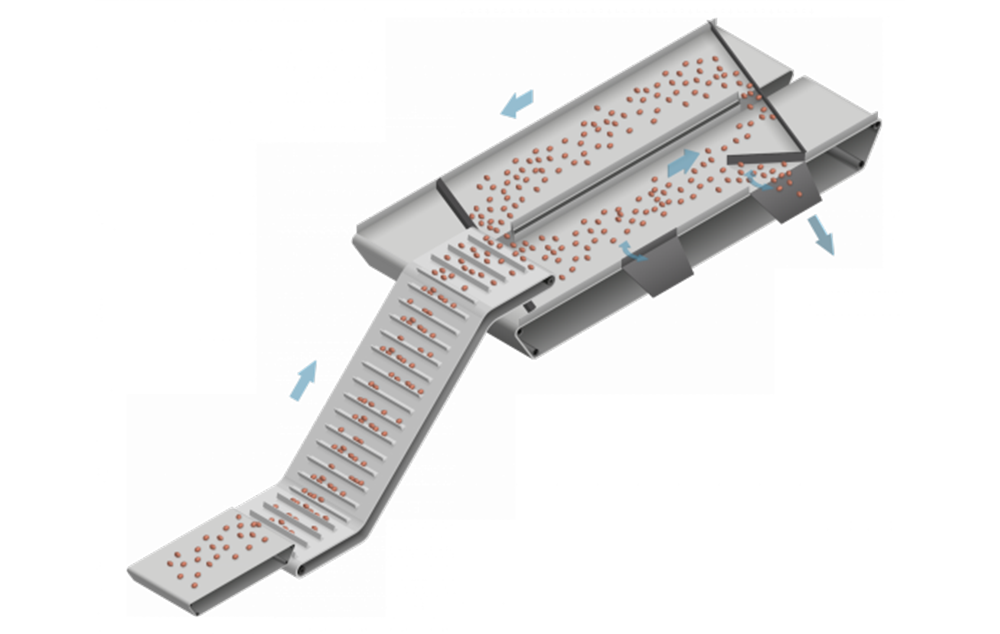

Inclined Conveyor with Feeding System MF2

- Transport of wrapped or unwrapped products (bulk goods – especially hard candies)

- Transport of the products to a different level

- Product supply conveyor to transfer the unwrapped candies to the wrapping machines

- Pneumatically driven product guides transfer the products to the feeding sections of the wrapping machines

- Re–circulation conveyor – running parallel to the product supply conveyor in opposite direction to recirculates any product not distributed to the wrapping machines

- Main discharge conveyor collects the wrapped product and connects to secondary packaging (bagging/cartooning )

- Three-phase motor driven conveyor, frequency controller integrated within the switch cabinet

- Easy access for cleaning through removable conveyor support plates

- Quick tensioning devices for the conveyor belts for easy maintenance and service

- Rotating brushes and scrapers provide constant automatic cleaning

- Fully removable waste trays

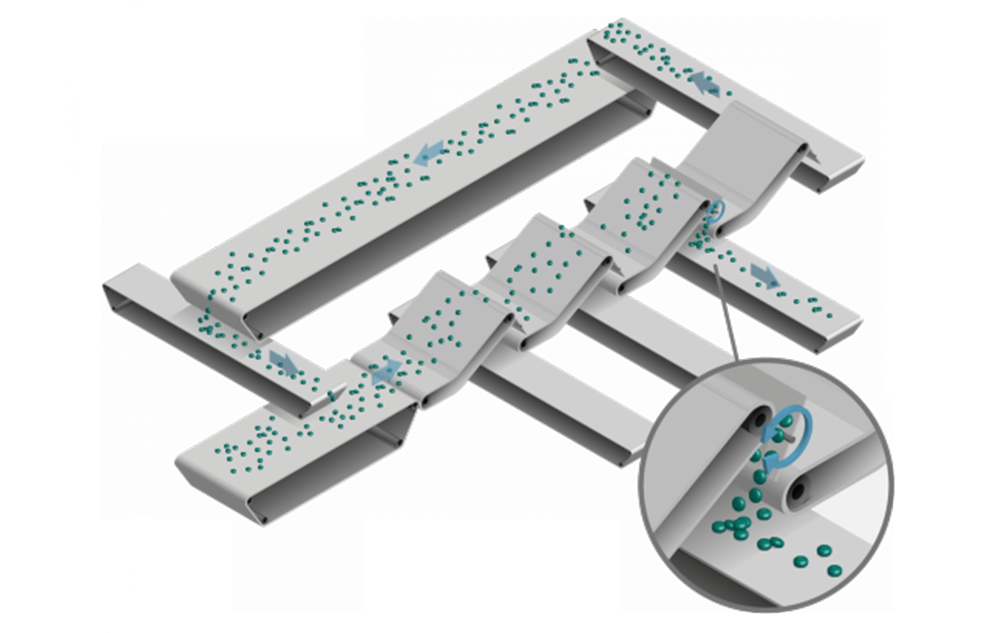

Feeding System MF3 for Jelly

- Transport of unwrapped products (bulk goods – especially jelly)

- Product supply conveyor to transfer the unwrapped candies to the wrapping machines

- Cascading conveyors with vertically arranged and pneumatically driven product guides

- Re–circulation conveyor – running parallel to the product supply conveyor in opposite direction to re–circulates any product not distributed to the wrapping machines

- Main discharge conveyor collects the wrapped product and connects to secondary packaging (bagging/cartooning )

- Three-phase motor driven conveyor, frequency controller integrated within the switch cabinet

- Easy access for cleaning through removable conveyor support plates

- Quick tensioning devices for the conveyor belts for easy maintenance and service

- Rotating brushes and scrapers provide constant automatic cleaning

- Fully removable waste trays

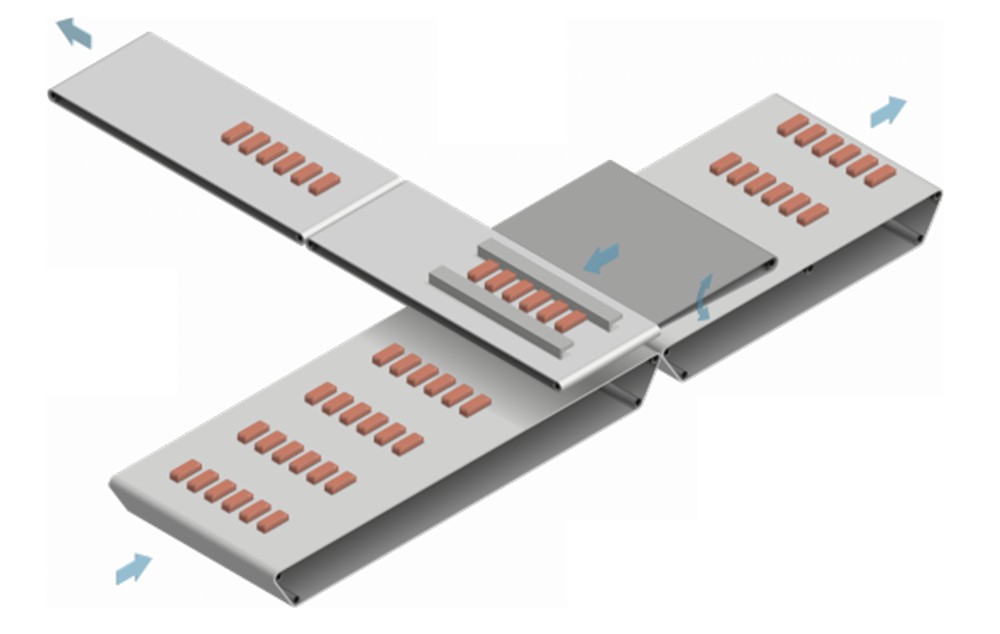

Row Doubling

- To distribute the incoming row structures to two levels

- Doubling of the row width, thus reducing the row rate

- Three-phase motor driven conveyor, frequency controller integrated within the switch cabinet

- Pneumatic web tracking control

- Easy access for cleaning through removable conveyor support plates

- Quick tensioning devices for the conveyor belts for easy maintenance and service

- All product transfers and scrapers with underneath sliding waste trays

- Return shafts with diameter 10 mm for smooth product transfer