LogiCX

Automatic coating system for both sugar and chocolate coatings with capacity of up to 250kg per batch.

Products Range

A wide range of centers

- Dried fruits, seeds, nuts…

- Toffees, caramels, liquorish…

- Biscuits, extruded products

- Chewing gums and chewy candies

A wide range of coatings

- Any type of chocolate, plain, milk, white

- Compounds and yogurt

- Equipment designed to work with a wide range of temperatures, fat concentrations and viscosities

- Same equipment will allow chocolate coating and varnishing during one batch

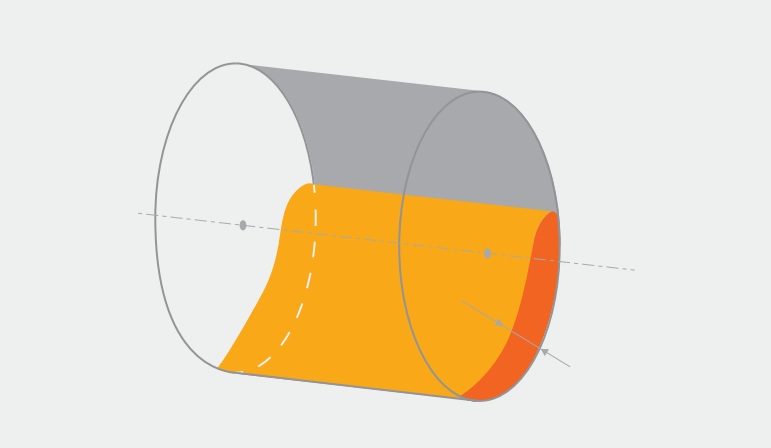

Drum Design

Shallow bed depth

| USEFUL VOLUME | 329 Liters |

| BATCH SIZE | 100-250 kg |

| DIAMETER | 1400 mm |

| LENGTH | 940 mm |

| PRODUCT BED DEPTH | 357 mm |

- Elongated drum shape for lower bed depth

- Careful handling of fragile products

- Better mixing

- Better exposure to ventilation and spraying

Mixing baffles

- Various materials, sizes, angles according to your products

Chocolate Spraying

Chocolate dosing and spraying

- Suitable for hard sugar coat,sugarless coat, glazing or varnishing

- Air flow through products bed

- Low pressure drop for better efficiency

- Faster drying time

Chocolate spray guns

- Hot jacket water and air spray system to give fine droplets

- Over-wetting at end of the process for smoothing

VARNISHING

- Varnishing solution tanks for aqueous and alcoholic solution

- Varnish dosing systems for controlled steps

- Varnish spraying systems in the pan with airless spray guns

- Varnishing of chocolate coated products will usually consist in 1 to 3 layers of aqueous varnish and layer of shellac

- Varnishing takes place after chocolate coating in the same batch

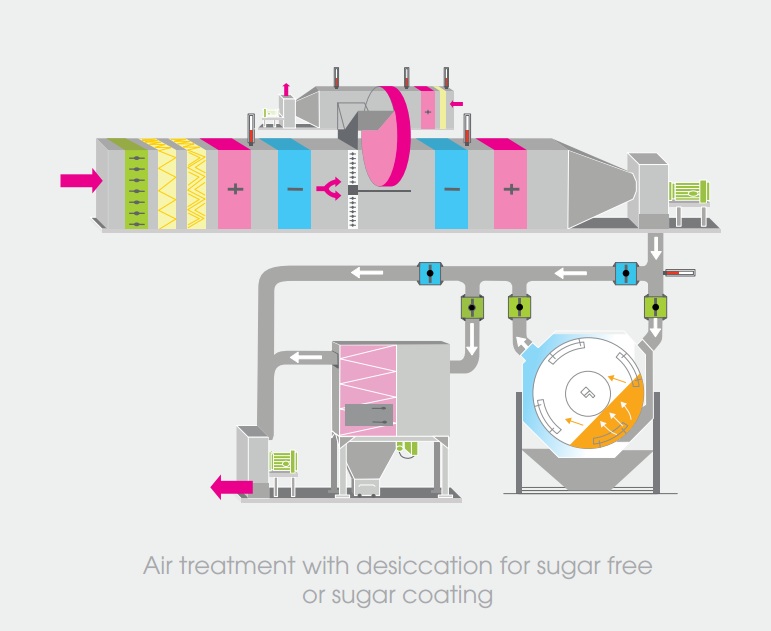

AIR TREATMENT GROUP

Process Air

- Airflow, temperature and humidity control

- Perfect repeatability

- Ventilation on top of products bed

Exhaust air

- Negative pressure inside pan

- Optional for dusty centers: Filter with pneumatic cleaning and dust collection

Closed system for energy saving

- Recirculation during chocolate coating (cool air) and fresh air intake during varnishing

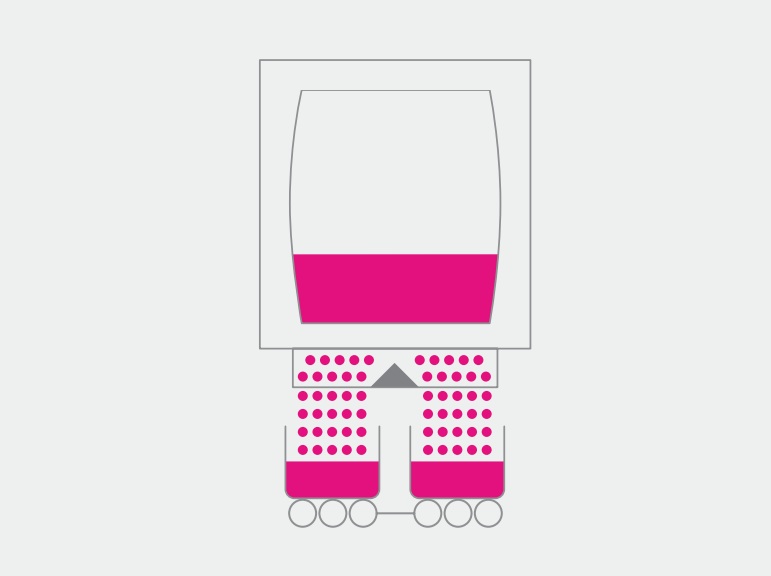

UNLOADING SYSTEM

Fast unloading system by traps allowing to start next batch very quickly. Finished products are unloaded into Eurobin containers for easy handling.

INFRARED CLEANING SYSTEM

- Used to melt down chocolate from previous batch,

thus building first layers of new batch - Less cleaning, more chocolate recovered

AUTOMATION

Automatic coating process according to recipes built with the touch screen and stored in the system

Product Brochure

Dumoulin-Minicoater-Logi-CX.pdf