EK1 – UP

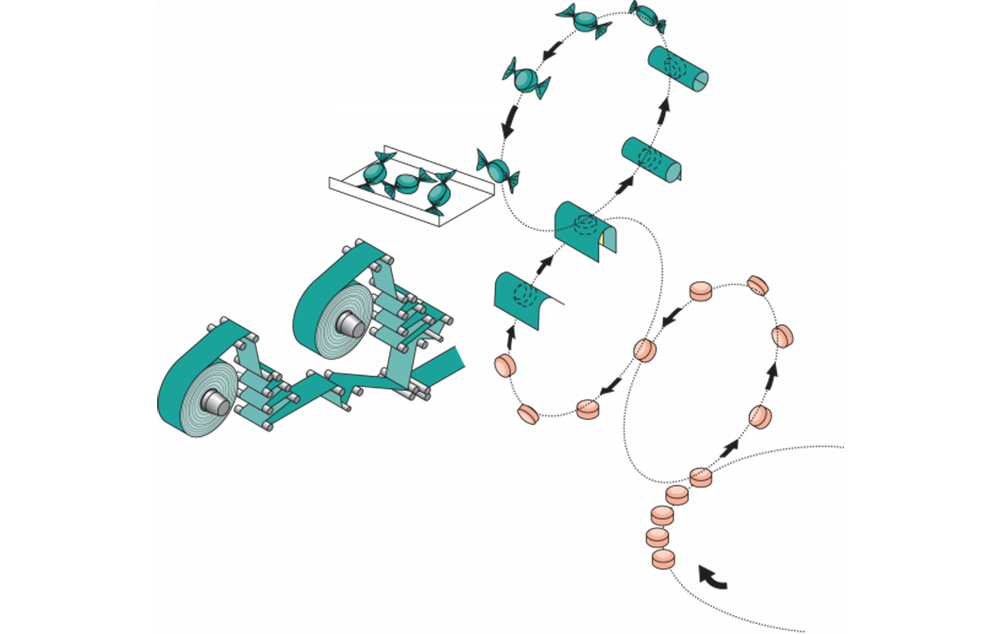

Upgraded continuous motion wrapping machine for hard candies in double twist. The mechanical, electrical and optical upgrade package enables higher performance, lower consumption of wrapping materials, enhanced operator comfort and reduces future maintenance.

Product Characteristics

Folding type

- Double Twist

Products

- Products suitable for plate feeding

- Hard Candys (with or without center-filling)

- Eclair

- Toffees

Product dimensions

- Length: 16 – 40 mm

- Width: 12 – 25 mm

- Height: 6 – 20 mm

Disc shaped products

- Ø 13 – 25 mm

- Height: 6 – 20 mm

Ball shaped products

- Ø 12 – 23 mm

Output

- Up to 1400 products/min

Technical Data

Utilities

- Connected load: 8 kVA

- Compressed air consumption: 2m³/h; 600 kPa

Measurements

Machine:

- Length: 2915 mm

- Width: 1900 mm

- Height: 1850 mm

Switch cabinet:

- Length: 1000 mm

- Width: 400 mm

- Height: 1900 mm

Weight

- Machine: 2350 kg

- Switch cabinet: 300 kg

Wrapping material

- Wax paper

- Cellophane

- Polypropylene

- Polyethylene

Material dimensions

- Reel diameter: Up to 350 mm

- Reel width: Up to 120 mm

- Core diameter: 40 – 80 mm

Equipment & Options

Special features

Proven standard features

- Feeding and sorting station with separation of small and oversized products and sugar dust

- Gentle product separation by large diameter feed plate

- Optimized feed plate fill level controlled by an electronic scale

- Automatic wrapping speed control

- Infinitely variable adjustment of the twist gripper oscillation depending on the wrapping material quality

- Adjustment of the twisting angle in three steps (1,1; 1,6; 2,1 rotations)

- Mechanical (cone type) reel holders

- Reel end detection and automatic splicing

- Separation of spliced/double wrapped products and non properly registered products

Improvements and added value

- Replacement of the mechanical scanning wheel by a laser scanner

- Upgraded wrapping material feeding unit with two independent servo drives for wrapping material draw off and cutting

- Optimized “no product – no wrapping material” functionality

- Infinitely variable adjustment of the wrapping material cut off length for increased wrapping capacity and reduced wrapping material consumption

- Complete replacement of the electrical cabinet and all field devices

- ELAU C 200 motion control system with integrated PLC functionality

- Upgraded air support to allow the use of modern PP foils

- Reproducible setting of the air support via valve bank

- Improved operation and Diagnostics via SIEMATIC touch screen

- Improved access for cleaning and maintenance thanks to a new safety concept

Combinations

- Beside manual feeding, the machine can be directly synchronized to the production line by means of a Theegarten-Pactec feeding system.

Optional extras

- Photo-electric print registration

- Detection system for manufacturer splices

- Different executions of the twist grippers for different wrapping materials

- Special execution for moulded toffees

- Remote diagnostics

Product Brochure

EK1_ENG_18_1_web.pdf