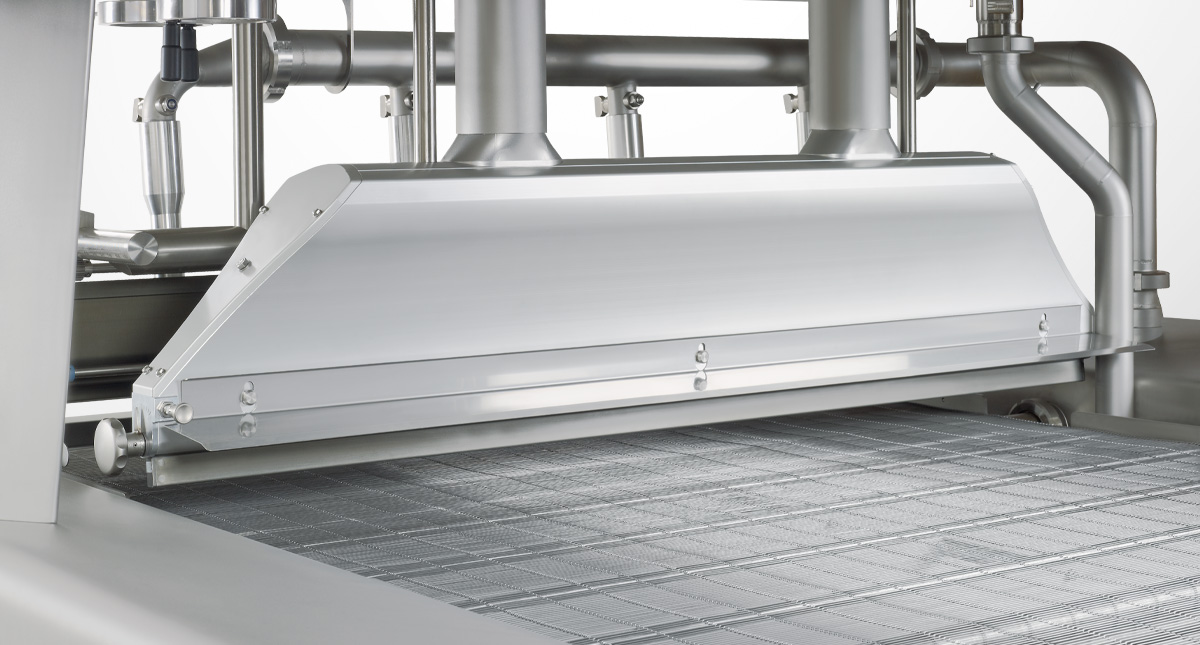

Enromat® M6

Number one for quality coating! The Enromat® M6 offers the highest quality for a wide range of applications in every performance range. The modular design of the machine allows it to be adapted to any product requirement.

Further improvements to the hygienic design – making cleaning and maintenance even easier – are characteristics of the new M6 generation. Special product requirements can be individually adjusted. Constant coating weights, durable gloss and improved shelf life of the products are outstanding features and the result of a high technological standard.

The ENROMAT® M6 – Custom is one of our best-selling chocolate enrobers and suitable for most types of application. It has numerous special design features, many of which have been patented. The hygienic design, ease of maintenance, ease of operation and the outstanding quality of the enrobing are worth special mention. The ENROMAT® M6 – Custom represents a logical development from the successful M5 series of chocolate enrobers.

The machines are suitable for full, half or bottom-coating of pralines, bars, pastries etc. with real chocolate or chocolate compound.

CHARACTERISTICS OF THE ENROMAT® M6 – CUSTOM:

- Modular expandable construction

- Excellent accessibility due to 2-column design

- Wire mesh belt lifting for easy cleaning

- External temperature control for chocolate

- Gentle mass circulation through adjustable Sollich pawl pump

- Uniform adjustable bottom bath through frequency controlled bottoming roller

- Easy to reproduce double curtain station

- Blow-off device with only +/- 1 % deviation over the working width

- Effective mechanical shaking device

- Detailer without any straps (patented) easily removable

- Length: 1.95m

- Available belt width: 820mm (32″) – 2600mm (102″)

ADDITIONAL EQUIPMENT

As well as the option to extend the enrobing line by the addition of a Thermo-Flow® plus cooling tunnel, a comprehensive range of extra equipment is available:

- bottom coaters and pre-coating machines

- top or polydimensional sprinkling devices

- strip coating device

- pressure curtain device

- product hold down drum roller

- wire-belt hold down device

- the DECORMATIC® automatic decorating system, Type DC4

- decorating rollers

- biscuit turn-over device

- product depositor and removal device

- truffle depositors

- truffle powdering and spiking stations

- cluster formers

- forming and extruding systems for pralines and bars

- chocolate tanks and pumps