FPH5

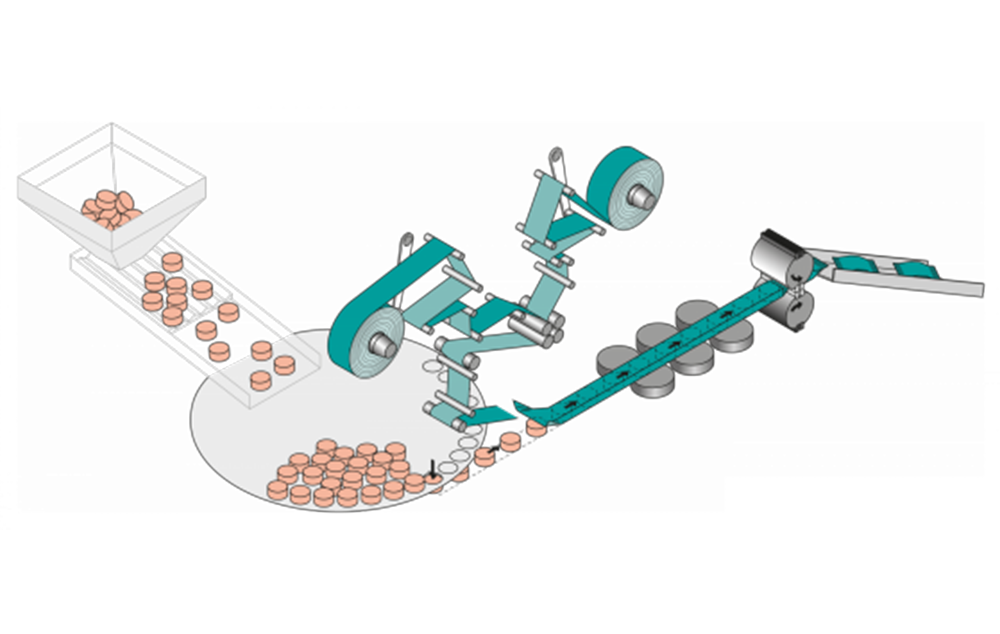

Modular high speed wrapping machine for preformed products

in flow packs. The flexible designs of the different assembly groups allow an attractive tailor-made adaptation of the machine to the customer needs.

Product Characteristics

Folding type

- Flow Pack

Products

- Products suitable for plate feeding

- Hard Candys (with or without center-filling)

- Eclair

- Jelly

Product dimensions

- Length: 15 – 45 mm

- Width: 12 – 30 mm

- Height: 5 – 18 mm

- Ø 15 – 30 mm

Output

- Up to 2000 products/min

Technical Data

Utilities

- Connected load: 10 kVA

- Compressed air consumption: 2 m³/h; 600 kPa

Measurements

Machine:

- Length: 3600 mm

- Width: 1600 mm

- Height: 1800 mm

Switch cabinet:

- Length: 1600 mm

- Width: 500 mm

- Height: 2100 mm

Weight

- 1800 kg

Wrapping material

- Cold sealable foil

- Heat sealable foil

Material dimensions

- Reel diameter: Up to 400 mm

- Reel width: Up to 160 mm

- Core diameter: 76,2 mm

- Wrapping material speed: Up to 140 m/min

Equipment & Options

Special features

- The machine is based on a modular design, consisting of a basic machine and modular main assemblies. These assemblies with optional functionalities can be adapted to the tailor-made machine

- Later amendments or upgrades of the machines are easy to implement

Combinations

- Beside manual feeding, the machine can be directly synchronized to the production line by means of a Theegarten-Pactec feeding system

Product and wrapping material feeding

- High filling efficiency of the feeding plate (plate diameter 1200 mm)

- Flexible feeding plate drive for different multi-packs and product sizes

- Manual or pneumatic core locking and reel tensioning devices

- Automatic splicer with or without print registration

- Manual or pneumatic web tracking control

- Print registration, detection system for manufacturer foil splices, code dating device, tear tape device, label dispenser

Sealing device

- Two or three-stage longitudinal sealing device for cold or heat sealing

- Long seam sealing profile in longitudinal direction

- Position retention belt

- Segmented cross sealing device for cold and heat sealing with up to four sealing jaws

- Cross seam sealing profile in longitudinal or transversal direction

Product discharge

- Discharge chute or discharge conveyor with separate drive

- Ejecting device for faulty packs

- Suction device for empty pouches

Operation

- Due to the automatic operation, several machines can be handled by one operator

- Easy operation due to the touch screen

- Excellent accessibility for operation, maintenance and cleaning purposes

Product Brochure

FPH5_ENG_19_1_web.pdf