MCH

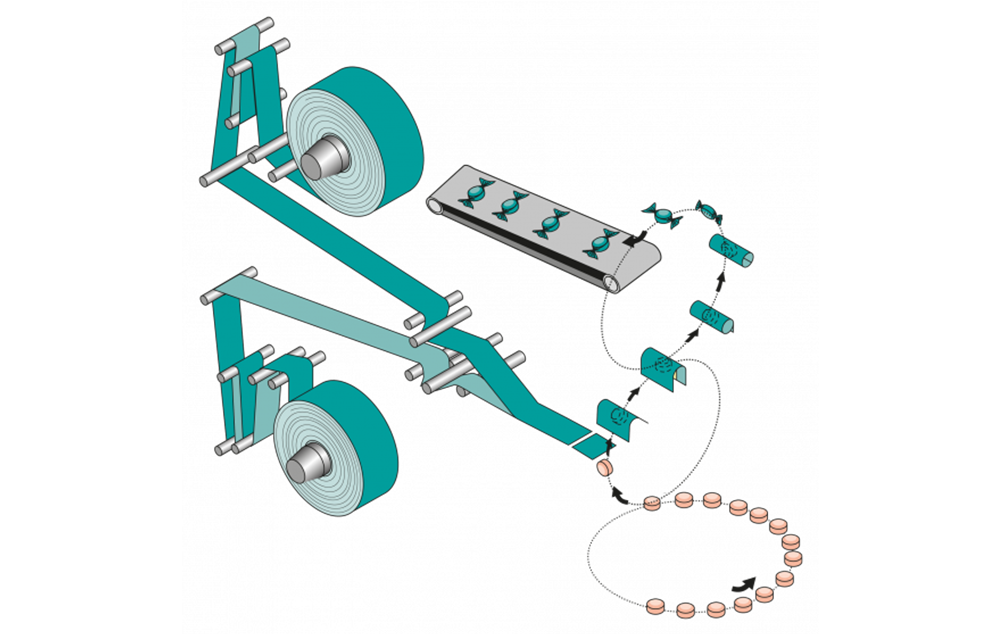

High performance and flexibility combined in one wrapping machine. The modular design enables the processing of different products and wrapping styles. And the continuous motion principle ensures high performance.

Product Characteristics

Folding type

- Double Twist

- Side Twist – Sachet

- Side Twist – Basket

- Protected Twist

- Vienna-Fruit-Fold

- Foil Wrap

Products

- Products suitable for plate feeding

- Hard Candys (with or without center-filling)

- Eclair

- Enrobed Products

- Jelly

Product dimensions

- Length: 16 – 45 mm

- Width: 12 – 25 mm

- Height: 6 – 25 mm

disc shaped products

- Ø 13 – 33 mm

- Height: 6 – 25 mm

ball shaped products

- Ø 13 – 33 mm

Output

- Up to 1200 products/min Double Twist and Foil Wrap

- Up to 1100 products/min Side Twist

- Up to 800 products/min Vienna-Fruit-Fold

Technical Data

Utilities

- Connected load: 13 kVA

- Compressed air consumption: 1m³/h; 600 kPa

Measurements

Machine:

- Length: 2960 mm

- Width: 2700 mm

- Height: 1780 mm

Switch cabinet:

- Length: 1200 mm

- Width: 500 mm

- Height: 2000 mm

Weight

- Machine: 2900 kg

- Switch cabinet:380 kg

Wrapping material

- Wax paper

- Cellophane

- Polypropylene

- Polyethylene

- Aluminium foil

Material dimensions

- Reel diameter: Up to 400 mm

- Reel width: Up to 140 mm

- Core diameter: 70 – 76,2 mm

Equipment & Options

Special features

“A particularly gentle handling of the products is guaranteed by the continuous motion principle”

- Highly efficient feeding system with integrated sorting station to eliminate sugar dust, chips and broken pieces

- All electrical and electronic components are located in a separate switch cabinet

- Air support to allow the use of PP foils

- Servo-driven wrapping material feed rollers and wrapping material knife

- Saving of wrapping material by “no product – no paper” device

- Electro motor-driven pneumatic reel centring and core locking devices

- Automatic splicer to change wrapping material reels without stopping the machine

- Infinitely variable adjustment of the twist gripper oscillation depending on the wrapping material quality

- Adjustment of the twisting angle in three steps (1,1; 1,6; 2,1 rotations)

- Ejection of spliced, mal-registered and unwrapped products

- Discharge of wrapped products by means of ejection device and discharge conveyor

- Excellent accessibility for operation, maintenance and cleaning purposes

- Easy operation due to the touch screen

- Due to the automatic operation, several machines can be handled by one operator

- System of protection: IP 54

Combinations

- Beside manual feeding, the machine can be directly synchronized to the production line by means of a Theegarten-Pactec feeding system.

Optional extras

- Modular machine design in order to facilitate the change of wrapping style and/or product dimensions

- Feeding and separation system in accordance to the requirements of the product to be wrapped

- Additional reel holders for a second wrapping material (under strip) with automatic splicer

- Wrapping material feed for inner and outer wrapping material with optional displacement of the inner wrapper to guarantee a high wrapping quality

- Photo-electric print registration

- Remote diagnostics

Product Brochure

MCH_ENG_21_1_web.pdf