Sollcofill® Creme Depositing Systems

Sollcofill® Moulding Plants – Moulding of fatty and sugar masses with accurate weight control

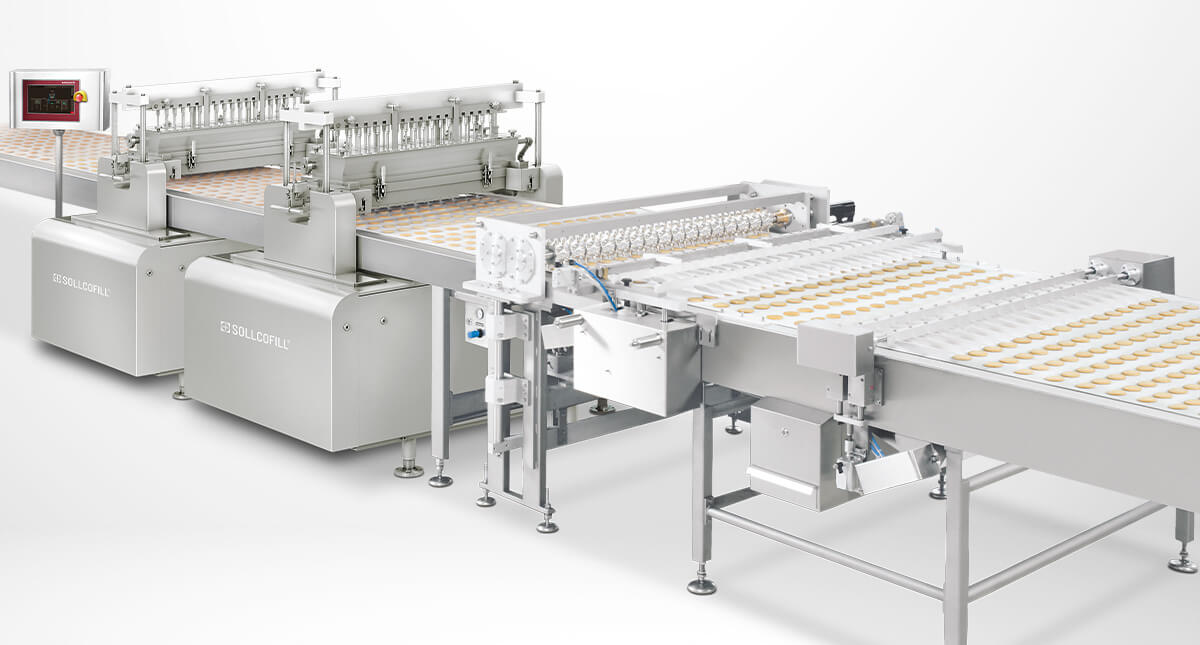

Sollcofill® is the name of the comprehensive range of depositing machines available from SOLLICH. A popular application is for depositing fatty and sugar masses in or on biscuit and wafer bases. The Sollcofill® plant illustrated on the left comprises the automatic biscuit aligning device and the double-row depositing plant, followed by a vibrating station and an automatic belt washing plant.

Sollcofill® offers a multitude of value added features to biscuit and baked products. This most avant-garde servo driven depositing and piping technology allows you to fill almost any baked product with fillings such as caramel, fondant, praline paste, jelly, milk and yogurt creams, chocolate etc., which have suitable flow characteristics. Further options are a laterally wheel-away depositing machine or the extension with a Sollcocap® sandwiching machine.

Precision filling of biscuits and wafers

Biscuits or wafers can be fed into the plant semi-automatically via magazine depositors or direct from the oven. An automatic row alignment device ensures the products are fed accurately into the depositing machine. If desired, depositing can be carried out using two colours simultaneously (‘one shot’ technology), or a sprinkling device can follow the moulding process.

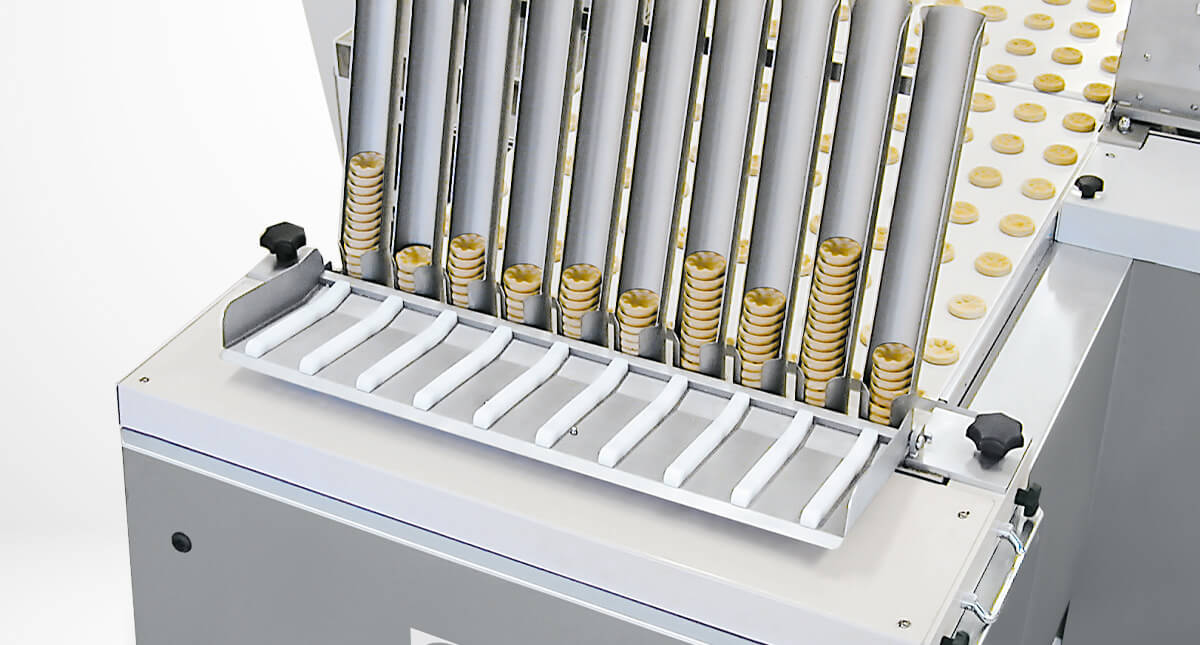

Nut Depositor

Additional interesting possibilities are offered by combining the Sollcofill® moulding plant with our automatic nut depositor. The nut depositor can place whole hazelnuts or macadamia nuts in position in groups of 1 to 4 or alternatively it can dispense chopped nuts by volume. The moulding machine dispenses liquid nut creme, chocolate or caramel on the pastry or directly onto the cooling belt to provide an adhesive base for the nuts.

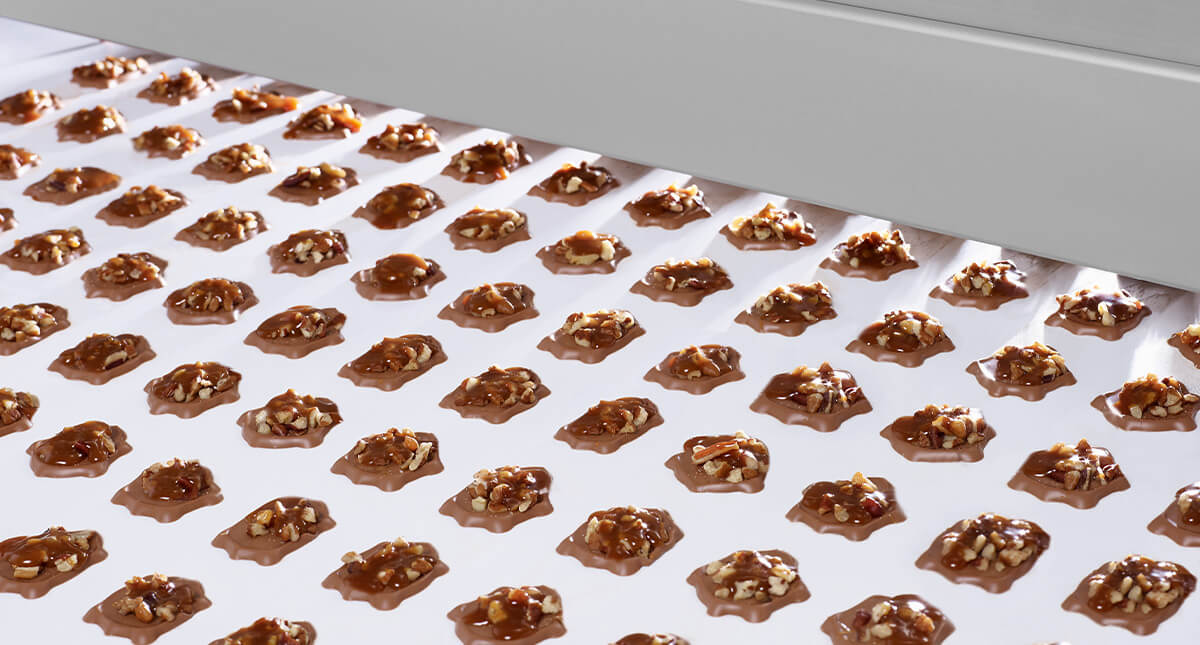

Caramel Cluster Depositor

Another popular use of Sollcofill® plants is to manufacture the caramel nut clusters so popular in North America. The Sollcofill® depositing plant deposits measured amounts of hot caramel onto a continuously running cooling belt, followed by the nut depositor which dispenses a measured volume of nuts and then a special “retro-moulder” which gives the item its final shape. The nut depositor is also suitable for depositing or inclusion of cherries, dragees, crisped rice or raisins.

Sandwiching Plant Sollcocap®

The all-purpose Sollcofill® can be used e.g. for filling biscuits, cakes and wafer products. It makes the ideal sandwich former with auxiliary equipment.

Capacity:

35-40 rows of sandwiches/min. by means of a vacuum turnover station after depositing and with two vacuum turnover stations up to 70-80 sandwich rows/min.

Outstanding characteristics

- hygienic design, all parts coming into contact with the product are made from stainless steel to maximise cleanliness and ease of cleaning

- jacket depositor hopper including sealed hot water circulation system

- for machine widths of 420, 620, 820, 1050 and 1300 mm

- 30-70 strokes per minute depending on the type of product

- versions ranging from 8 items per stroke with nozzles 50 mm apart on a single-row moulding machine up to 96 items per stroke with nozzles 40 mm apart on triple-row moulding machines

- 12, 16, 20 and 24 mm piston diameters available

- each piston can be individually adjusted

- if required, each moulding machine can be fitted with a device to raise the belt for moulding/forming pointed items or to break off the tail when viscous masses are being used.