Storage Systems

The intermediate storage of unpacked products allows the compensation of downtimes and the integration of technological processes.

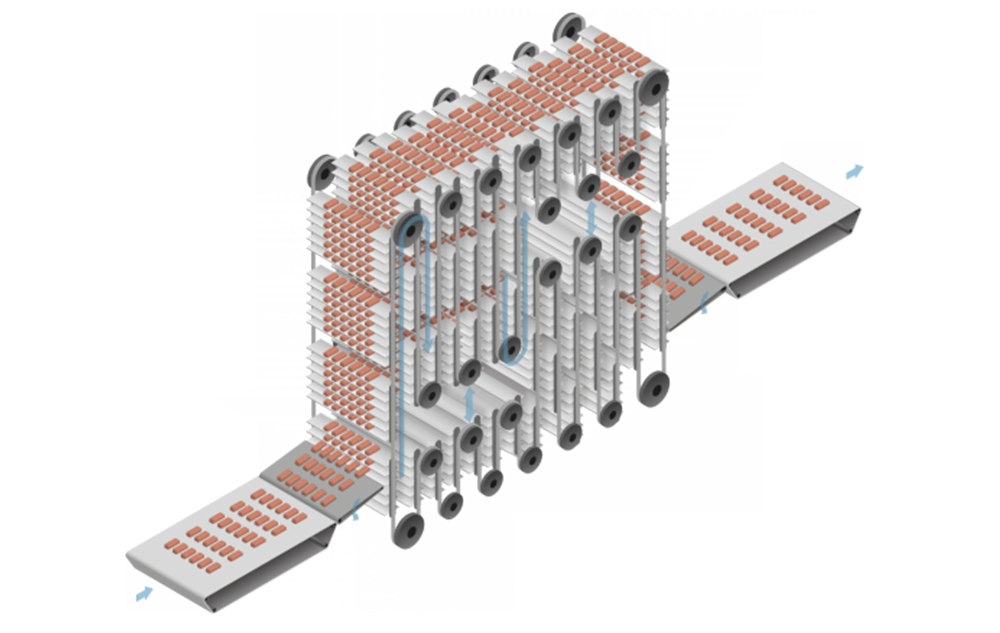

Plate and Counter Mould Storage System

- The storage system is equipped with two vertical conveyors

- The counter moulds or plates are transferred to the first vertical conveyor

- Transfer of the plates or counter moulds to a second vertical conveyor by a travelling transfer device

- Travelling transfer device is positioned automatically at the highest occupied level of the vertical conveyors

- At the bottom level of the second vertical conveyor the counter moulds are transferred to a horizontal conveyor, which leads to the wrapping process

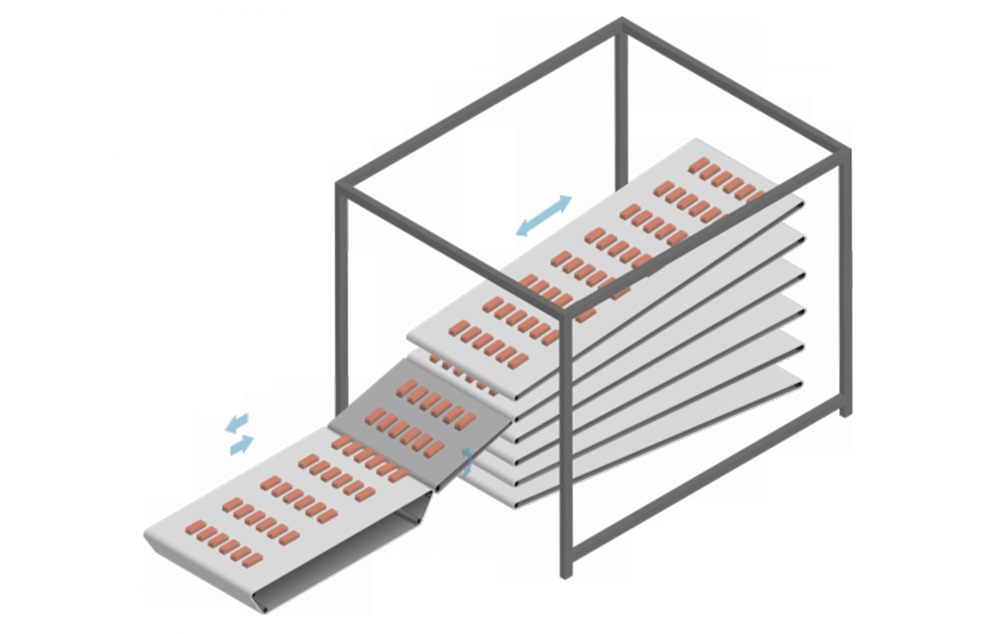

Fan Type Storage System

- Fan type storage system with different belt levels

- Products are distributed automatically to the belt levels

- Loading and unloading through reversing mode of the feeding belt

- Overflow storage of a production or packaging line (First IN/Last OUT)

- Three-phase motor driven conveyor, frequency controller integrated within the switch cabinet

- Servo-driven feeding belt

- Easy access through swivelling guard doors

- Pneumatic web tracking control

- Easy access for cleaning through removable conveyor support plates

- Quick tensioning devices for the conveyor belts for easy maintenance and service

- All product transfers and scrapers with underneath sliding waste trays

- Return shafts with diameter 10 mm for smooth product transfer

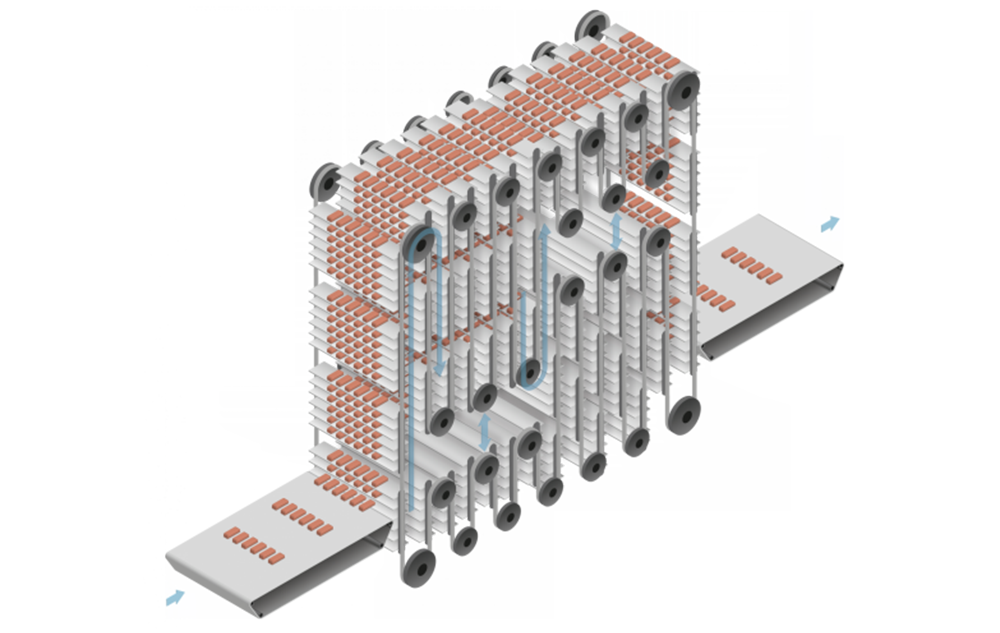

Gondola Storage System

- Storage of products in multi-level gondolas

- Compensation of irregular output of the processing line

- First IN/First OUT technology

- Modification as an overflow storage system at the end of the production line by loading and unloading on the same side (First IN/Last OUT technology)

- Loading and unloading of the products alternatively across or in line

- Simultaneous loading and unloading at different speeds through two independent servo drives of the gondola chains

- Easy access through swivelling guard doors

- Convenient maintenance and cleaning through removable gondolas

- Modular design enables later amendments

- Optional: Implementation of technological processes (e.g. cooling, drying)

- Optional: Fast loading through servo driven loading unit at continuous and smooth gondola operation

Buffer Conveyor System with Vibratory Pre-Buffer and Re-Feeding Conveyor

- Products not distributed to the wrapping machines might overflow at the end of the system

- Integrated travelling diverter, which travels, across the conveyor to equally distribute products over the conveyor width

- Vibratory pre – buffer compacting station which arranges product overflow in a carpet structure

- Buffer conveyor to store the products (storage capacity depends on length and widths)

- Re – feed conveyor to re – feed product to the main feeding conveyor for repeated integration into the wrapping process

- pneumatic web tracking control

- Easy access for cleaning through removable conveyor support plates

- Quick tensioning devices for the conveyor belts for easy maintenance and service

- All product transfers and scrapers with underneath sliding waste trays

- Return shafts with diameter 10 mm for smooth product transfer