Turbotemper ® e Liquid

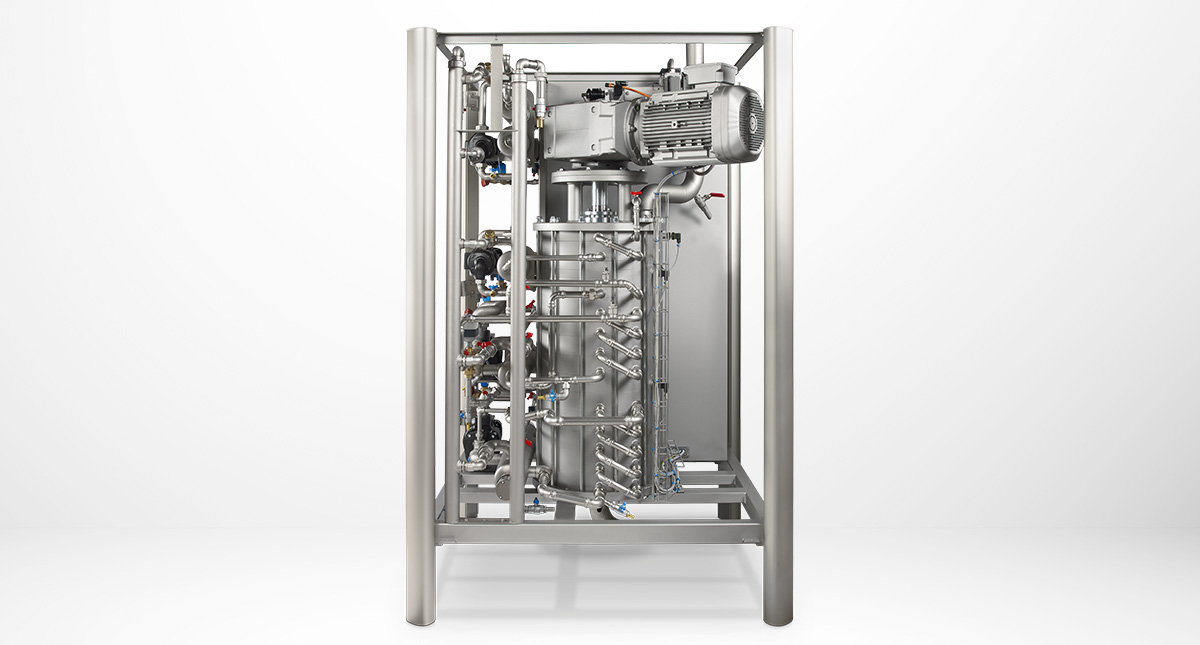

The Turbotemper®e Liquid was designed to feed moulding plants for hollow goods where the process parameters dictate a chocolate with low viscosity and low flow rates.

Features

- Low viscosity at high initial temperature

- Constant degree of temper, even with varying chocolate infeed temperatures or throughputs

- First-in/First-out principle

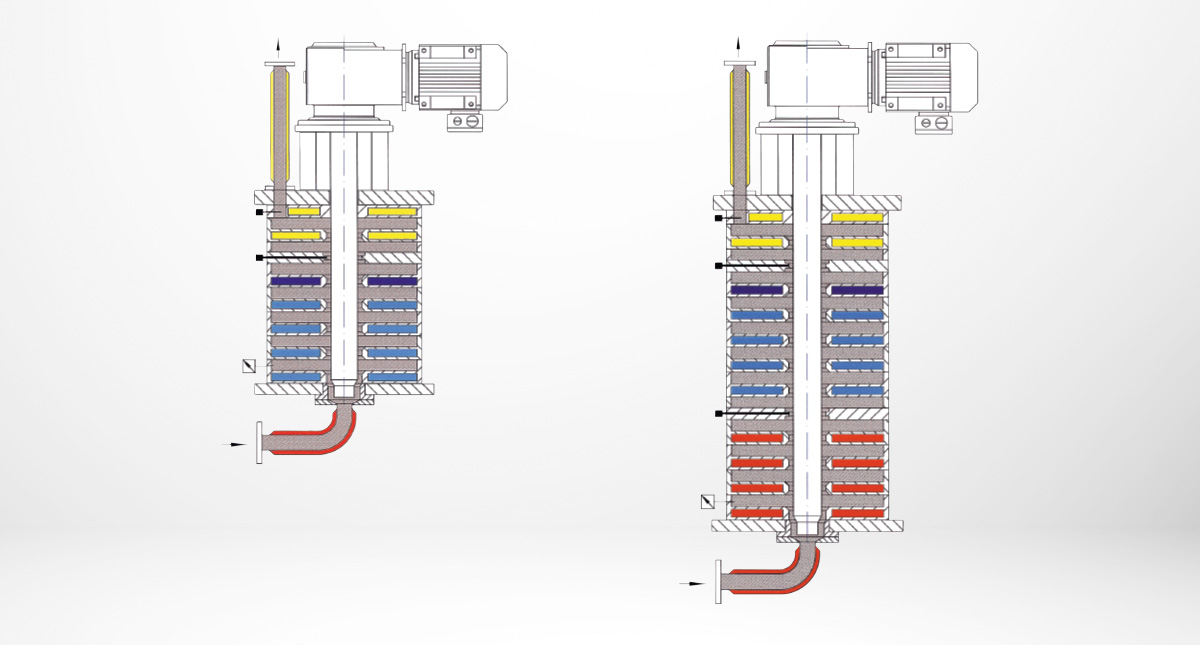

- Homogeneous crystal distribution due to patented scrapers

- Greater temperature control capacity and economy thanks to patented cooling discs

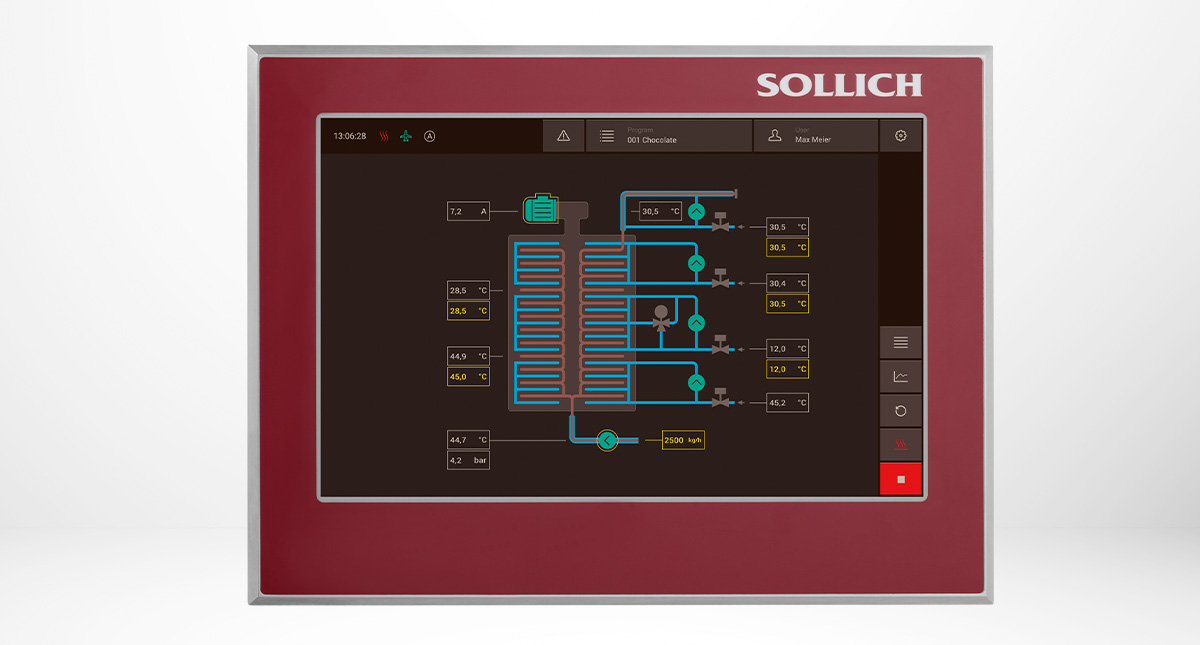

- High operating comfort and extensive data management

- Available with integrated decrystallization stage

- Capacity: 100 to 19,000 kg/h (220 – 42,000lbs/h)