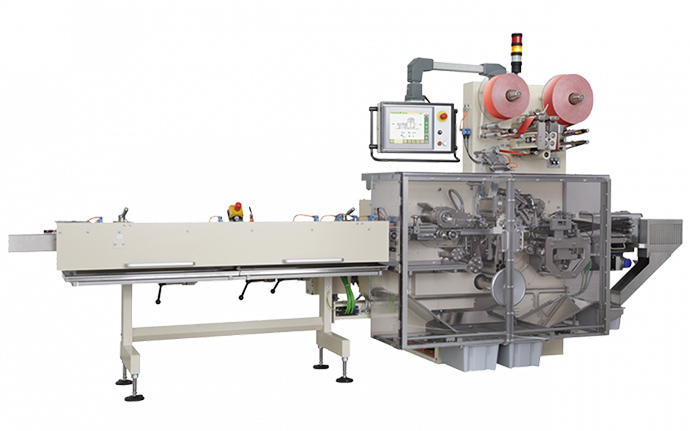

U1-C

High speed wrapping machine for chocolate bars and similar products in envelope fold

Product Characteristics

Folding type

- Envelope Fold

Products

- Chocolate Bars

Product dimensions

- Length: 30 – 120 mm

- Width: 15 – 45 mm

- Height: 6 – 15 mm

- Special sizes upon request

Output

- Up to 750 products/min

- Up to 350 products/min (width >= 30 mm)

Technical Data

Utilities

- Connected load: 12 kVA

- Compressed air consumption: 1,5 m³/h; 600 kPa

Cooling water consumption:

- 0,15 — 0,21m³/h

- Temperature: 10 … 15°C

- Pressure: min. 200 kPa

Measurements

Machine:

- Length: 1600 mm

- Width: 1310 mm

- Height: 2000 mm

Feeding unit:

- Length: 2100 mm

- Width: 540 mm

- Height: 1100 mm

Switch cabinet:

- Length: 1200 mm

- Width: 500 mm

- Height: 2000 mm

Weight

- Machine: 1820 kg

- Feeding unit: 300 kg

- Switch cabinet: 300 kg

Wrapping material

- Aluminium foil

- Aluminium/paper-coated

- Cellophane

- Polypropylene

Material dimensions

- Reel diameter: Up to 350 mm

- Core diameter: 70 – 76,2 mm

Equipment & Options

Special features

- Electronically controlled product feed

- A continuous transport of the bars is achieved by precisely synchronised conveying speeds of the feeding conveyors in order to avoid any accumulation pressure to the delicate products

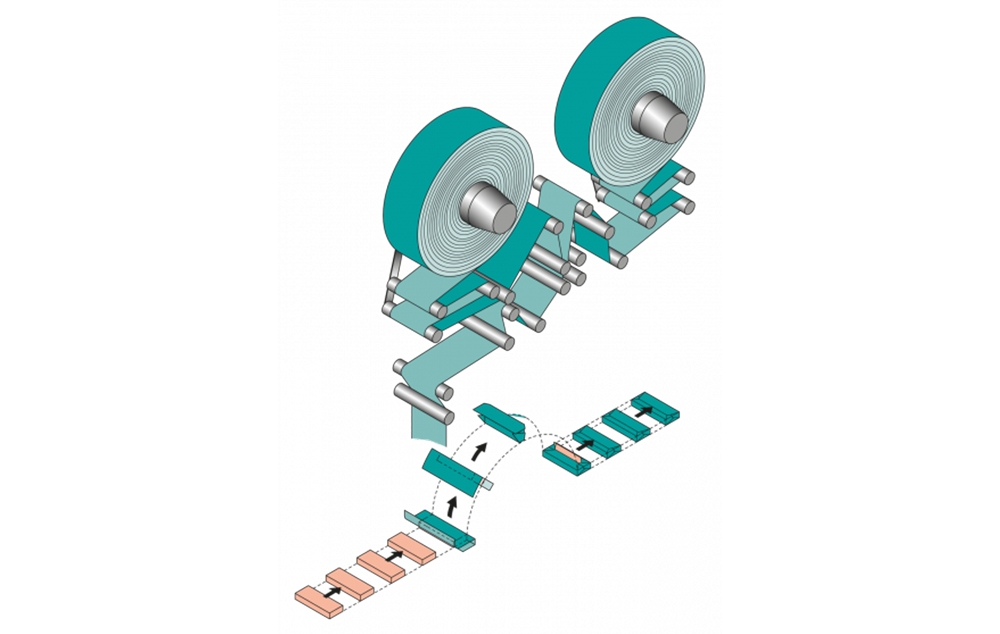

- Automatic splicer to change wrapping material reels without stopping the machine

- Pneumatic core locking and reel tensioning devices

- Servo-driven wrapping material feed rollers and wrapping material knife

- Servo control with PLC functions

- Central lubrication of all gear parts including oil pressure control/temperature control

- All electrical and electronic components are located in a separate switch cabinet

- Excellent accessibility for operation, maintenance and cleaning purposes

- Easy operation due to the touch screen

- Due to the automatic operation, several machines can be handled by one operator

Combinations

- Instead of a direct synchronization to the production line the machine can also be supplied with separate feeding systems, for instance if the bars are provided on feeding plates

- A synchronization with down-stream overwrapping (cartoning or flow-pack machines) machines is also possible

Optional extras

- Photo-electric print registration

- Special paper feeding device for the application of two separate wrapping materials (i. e. cellophane or PP films and aluminium/paper-coated) glued together on the machine by means of a gluing device

Ejection of spliced, mal-registered and unwrapped products

Product Brochure

U1-C_e_21.01.pdf