U1-DCW+F

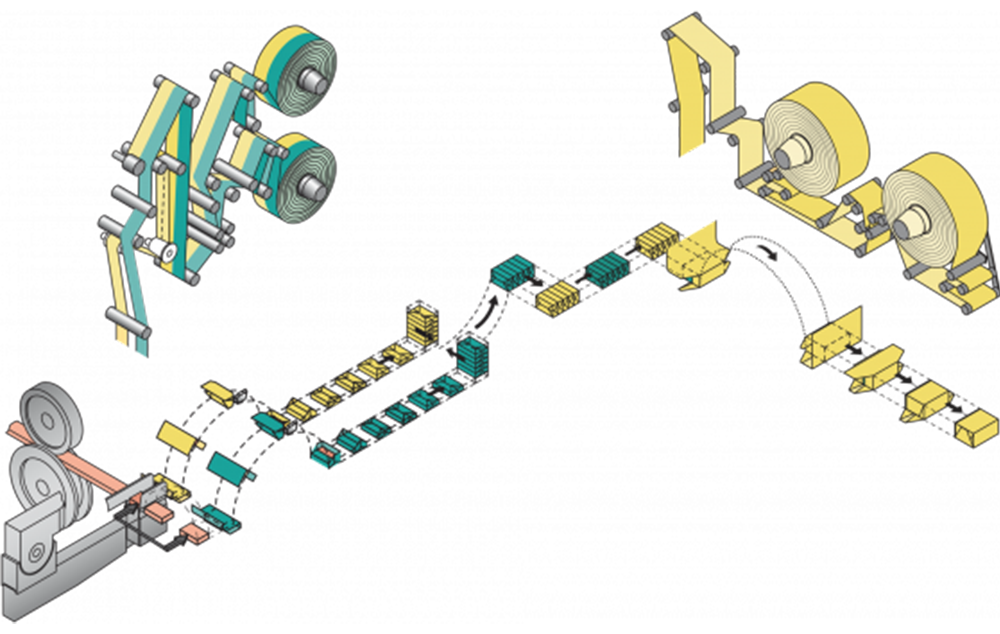

High speed plant to form, cut and wrap products in fold wrap with simultaneous overwrapping in flat stick packs or stick packs “on edge“.

Product Characteristics

Folding type

Primary packaging:

- Bottom Fold

- Side Fold

- Envelope Fold

Secondary packaging:

- Stick packs on edge

- Flat stick packs

Products

- Hard and Soft Caramels

- Toffees

- Chewy Sweets

- Chewing Gum

Product dimensions

U1-DCW:

envelope fold

Length: 30 – 35 mm

side fold, bottom fold

Length: 18 – 38 mm

Width: 12 – 25 mm

Height: 4 – 15 mm

Special sizes upon request

F3:

Stick Pack flat

Length: 44 – 140 mm

Width: 18 – 38 mm

Height: 6 – 15 mm

Stick Pack on edge

Length: 44 – 140 mm

Width: 18 – 30 mm

Height: 12 – 25 mm

Products per Stick Pack:

Stick Pack flat: 3 – 8 pieces

Stick Pack on edge: 3 – 16 pieces

Output

- up to 2000 single products/min

- up to 300 stick packs/min

Technical Data

Utilities

- Connected load: 22 kVA

- Compressed air consumption: 1.5 m³/h; 600 kPa

Cooling water consumption:

- 0.15 m³/h

- Temperature: 10 … 15°C

- Pressure: min. 200 kPa

Measurements

Machine:

- Length: 3377 mm

- Width: 3200 mm

- Height: 2382 mm

Switch cabinet :

- Length: 1800 mm

- Width: 500 mm

- Height: 2200 mm

Weight

- Machine: 5500 kg

- Switch cabinet: 350 kg

Wrapping material

- All common wrapping materials can be used

Material dimensions

U1-DCW:

- Reel diameter: up to 350 mm

- Core diameter: 70 – 76,2 mm

F3:

- Reel diameter: up to 350 mm

- Core diameter: 70 – 76,2 mm

Tear tape:

- Reel diameter: up to 120 mm

- Reel width: up to 100 mm

- Core diameter: 29 mm

Equipment & Options

Special features

- cutting and wrapping of products in fold wrap with simultaneous overwrapping in stick packs

U1-DCW

- two pieces are cut simultaneously by means of a double knife, wrapped in a dual track wrapping head and sealed in twin-lane discharge

- three stage stainless steel in-feed rope sizing and calibrating unit for precise adjustment of the rope dimension

- one pair of sizing rollers driven by an independent servo drive for precise adjustment of the rope speed

- water-cooled guillotine knife with intermittent rope feed for precise cutting

- longitudinal cutting device for twin lane processing of wrapping material reels of double web width

- automatic splicer to change wrapping material reels without stopping the machine

- Pneumatic core locking and reel tensioning devices

- servo-driven wrapping material feed rollers and wrapping material knife

- stationary unit for cycle precise sealing / tacking and cooling of the wrapping material fold

- central lubrication system of all gear parts with oil pressure control

F3

- photo-electric print registration

- tear tape device

- ejection of incomplete stick packs before wrapping

- automatic splicer to change wrapping material reels without stopping the machine

- pneumatic core locking and reel tensioning devices

- servo-driven wrapping material feed rollers and wrapping material knife

- Ejection device for incomplete, “spliced” respectively mal-registered stick packs

- stationary unit for cycle precise sealing / tacking and cooling of the wrapping material fold

General

- servo control with PLC functions

- all electrical and electronic components are located in a separate common switch cabinet

- excellent accessibility for operation, maintenance and cleaning purposes

- easy operation due to the touch screen

- depending on local conditions, one operator is required

- system of protection: IP 54

Combinations

- Depending on the product, the machine can be synchronized either with a batch roller and rope sizing machine (toffees, hard and soft caramels) or an appropriate extruder and cooling tunnel (chewing gum, bubble-gum, chewy candy).

Optional extras

- electronic rope speed control to match the machine and rope speed

- photo-electric print registration for singel products

- air support to stabilise wrapping material transport and transfer by valve bank with high precision throttle valves for exact and reproducible air support setting

- turning device 90° or 180° for stick packs at the discharge

- automatic wrapping material web tracking control for the secondary packaging to center the wrapping material feed in direction of travel

Product Brochure

U1-DCW_F3_ENG_19_1_web.pdf