U1-TR

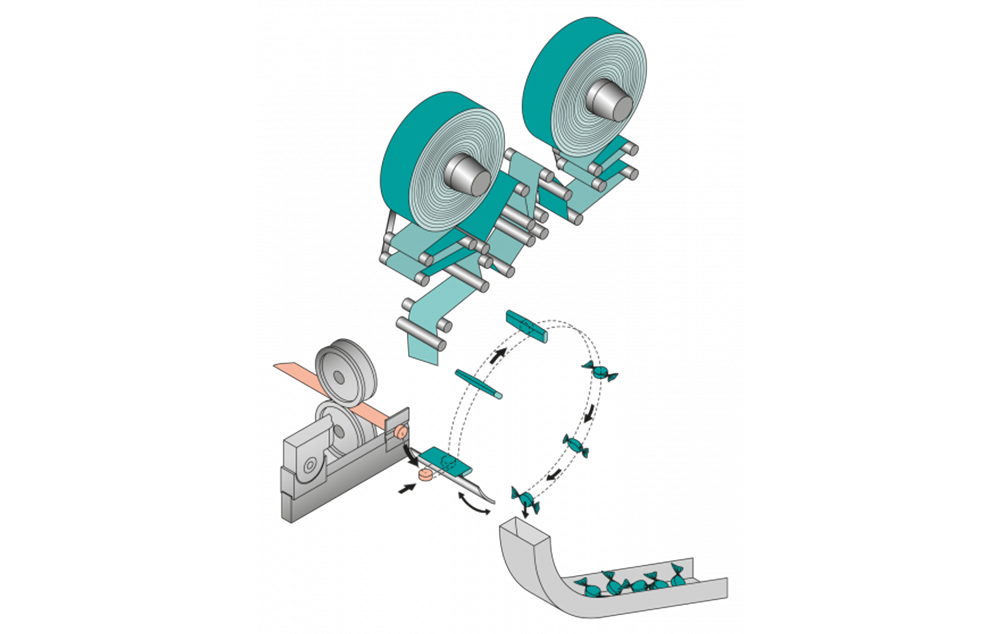

High speed forming, cutting and wrapping machine for products in double twist. The machine is designed to manufacture “Rocks” products.

Product Characteristics

Folding type

- Double Twist

Products

- Hard and Soft Caramels

- Toffees

- Chewy Sweets

- Chewing Gum

Product dimensions

- Ø 15 – 30 mm

- Height: 5 – 15 mm

- Special sizes upon request

Output

- Up to 800 products/min

Technical Data

Utilities

- Connected load: 12 kVA

- Compressed air consumption: 1,5 m³/h; 600 kPa

Cooling water consumption:

- 0,15 m³/h

- Temperature: 10 … 15°C

- Pressure: min. 200 kPa

Measurements

Machine:

- Length: 1860 mm

- Width: 1500 mm

- Height: 1975 mm

Switch cabinet:

- Length: 1200 mm

- Width: 500 mm

- Height: 2000 mm

Weight

- Machine: 2000 kg

- Switch cabinet: 270 kg

Wrapping material

- Cellophane

- Polypropylene

Material dimensions

- Reel diameter: Up to 350 mm

- Core diameter: 70 – 76,2 mm

Equipment & Options

Special features

- Two stage stainless steel in-feed rope sizing and calibrating unit for precise adjustment of the rope speed and dimension with air jets to cool and clean the sizing rollers from starch and product residues

- Water-cooled guillotine knife

- The pieces are cut vertically from the (normally round) mass rope and are then turned by 90° to be pushed horizontally into the mould wheel. Thus, the cut surface (different colours and designs) becomes visible.

- Pneumatic core locking and reel tensioning devices

- Automatic splicer to change wrapping material reels without stopping the machine

- Servo-driven wrapping material feed rollers and wrapping material knife

- Variable adjustment of the twisting angle to match the wrapping material memory

- Variable adjustment of the twist gripper oscillation to match the wrapping material elasticity

- Servo control with PLC functions

- Central lubrication of all gear parts including oil pressure control/temperature control

- All electrical and electronic components are located in a separate switch cabinet

- Excellent accessibility for operation, maintenance and cleaning purposes

- Easy operation due to the touch screen

- Due to the automatic operation, several machines can be handled by one operator

- System of protection: IP 54

Combinations

- Depending on the product, the machine can be synchronized either with a batch roller and rope sizing machine (toffees, hard and soft caramels) or an appropriate extruder and cooling tunnel (chewing gum, bubble-gum, chewy candy)

Optional extras

- Electronic speed control

- Photo-electric print registration

- Ejecting unit for unwrapped products

- Detection system for manufacturer foil splices of the wrapping material

Product Brochure

U1-TR_ENG_20_1_web.pdf