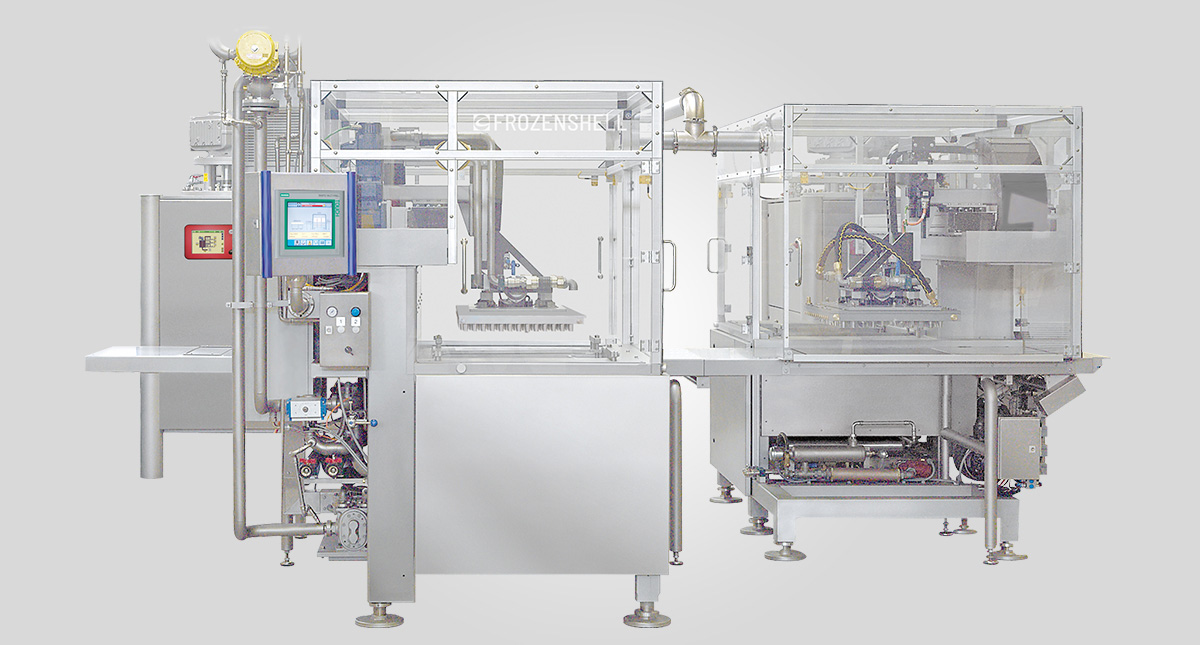

Frozenshell®

Chocolate shells for confections

Frozenshell® can form thin chocolate shells into a large variety of shapes. Low temperature form stamps are dipped into a bath of tempered chocolate. The depth of dipping determines the height of the chocolate shell. The stamp plate then deposits the shells onto a transport belt in perfect alignment, where they are slightly cooled. The Pralimat® depositor then fills the shells with the chosen praline mass.

By exchanging the stamp plate different shapes can be produced. The shape arrangement can also consist of different sizes on one plate.

Overview

A plate mounted with frozen tools is dipped into a bath of tempered chocolate. Depending on the depth and time of dipping different heights and thicknesses can be achieved.

The tool plate deposits the shells onto a transport belt in perfect alignment. Further downstream the shells can be filled with various fillings and decorations. The result of the Frozenshell®-Technology is a thin-walled shell, which allows for the use of both creamy and even free flowing fillings. Different shapes can be produced with readily interchangeable forming tools.

Technical Data

| Type | Category | Working width | Products/min |

| Frozenshell® | Chocolate | 420 mm | 234 pc. |

| Frozenshell® | Chocolate | 620 mm | 364 pc. |

| Frozenshell® | Chocolate | 820 mm | 612 pc. |