Conbar® Cereal Bars

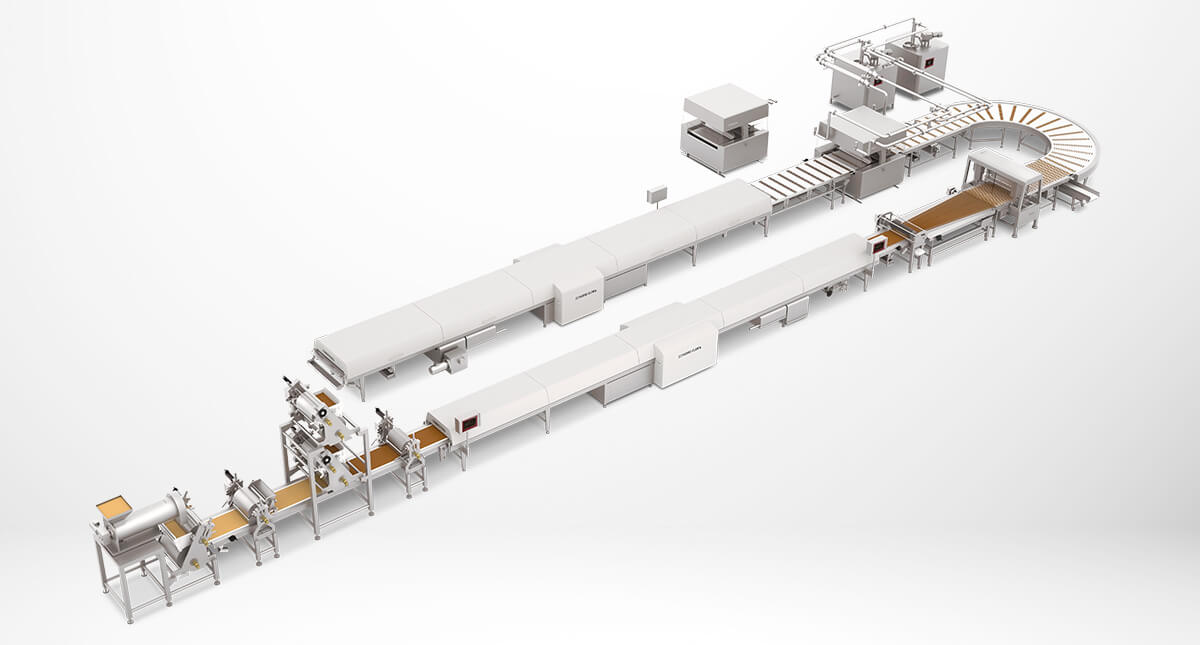

The SOLLICH Conbar® line is the unrivalled market leader in cereal bar manufacturing thanks to its enormous flexibility. Single-layer and multi-layer products with an additional layer of a milk or yoghurt creme, caramel, fruit mass or filling can be produced to the highest quality standards.

As well as products cut into rectangles, stamped bars with a variety of different cross-sections can be produced.

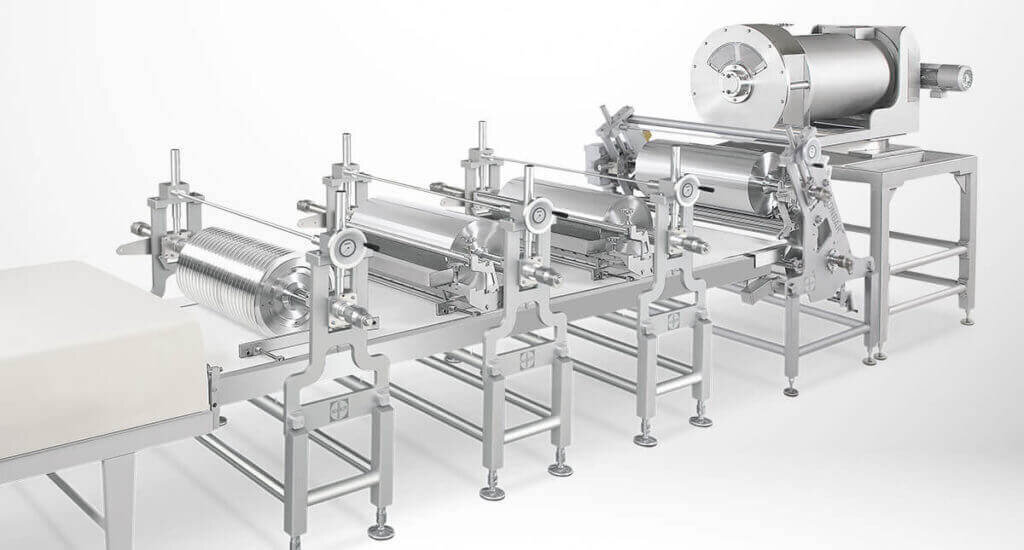

Conbar® roller formers allow:

- direct feed from the cooking plant or the mixer without the need for interim cooling

- cooling and moulding in a single machine

- gentle moulding without pressure, without changing the weight or structure of the mass

- easy changeover between products or changes to the product mass

Conbar® slab former options

For the production of cereal bars the following Conbar® slab formers are available:

- Conbar® roller former Type WEB for pre-forming the first layer of cereal, located in front of the infeed table

- Conbar® gauge roller for calibrating the pre-formed cereal slab to the required thickness and width, positioned above the infeed table

- Conbar® profiling roller for profiling the calibrated slab into semi-circular or differently shaped cross-sections

- Conbar® roller former Type WET for forming a thin, usually second, 2-5 mm layer of caramel, fudge or agar jelly on top of the cereal slab.

Conbar® bar manufacturing lines may be extended with mixers, cooling tunnels, cutting plants and chocolate refining equipment. The relevant cooking equipment is available in the range of products supplied by our sister company CHOCOTECH.

Product Brochure

Sollich-Conbar.pdf