Enromat® M6 – CIP

The Enromat® M6 CIP is the first enrober that can be automatically completely washed and dried. This process is computer-controlled.

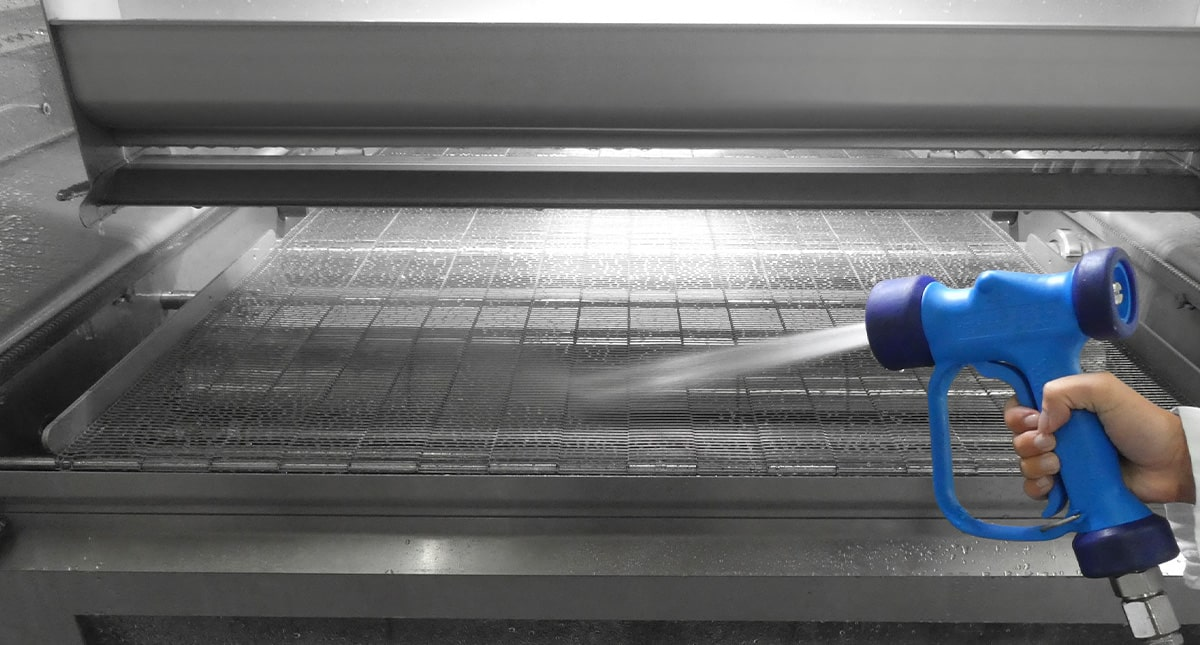

The CIP cleaning of the Enromat® M6-CIP is done automatically with hot water. The integrated spray nozzles target the soiled areas in several rinsing cycles. The operator can adjust the sequence of the washing and drying process to suit individual needs. The specially developed ahot water circulation system saves water and energy.

The patented system works on the principle of a dish washer. Hot water is circulated under pressure through spray nozzles in several washing circuits, followed by hot air drying.

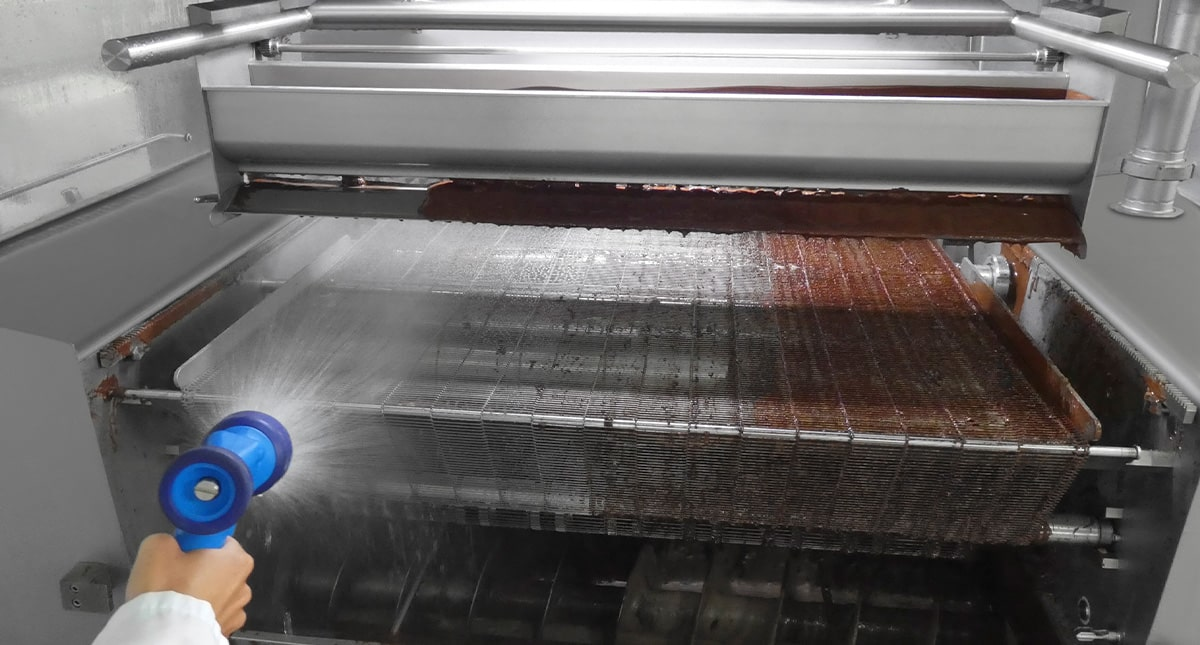

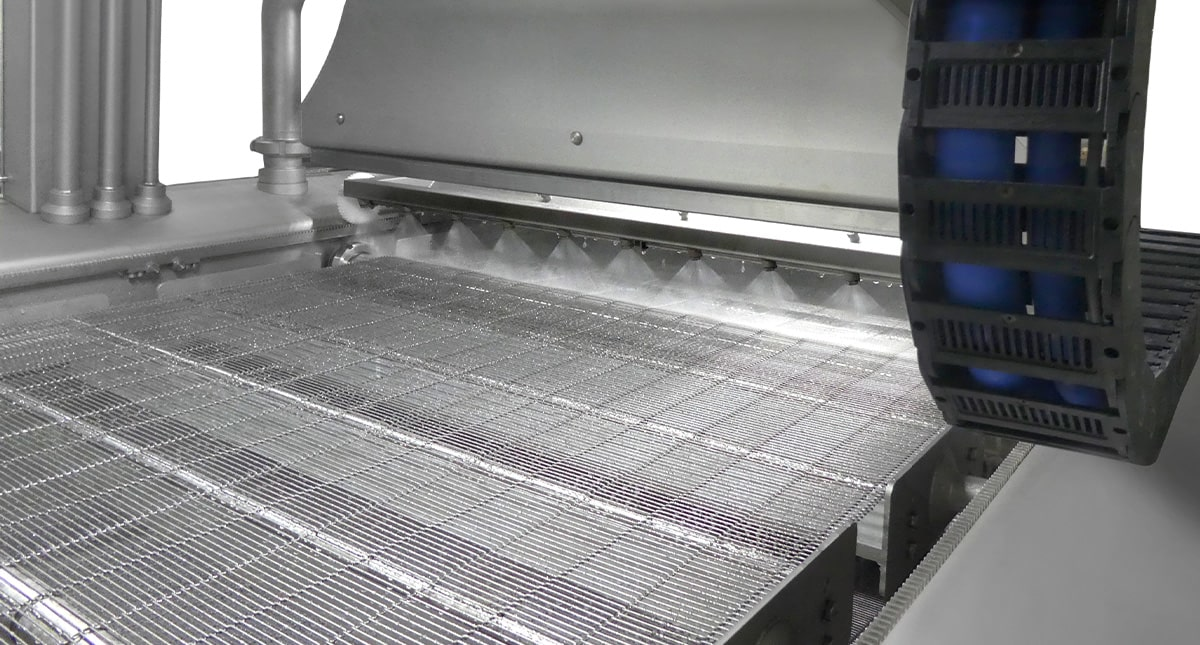

A new way of intensive cleaning with a computer-controlled wash-down trolley above the wire belt. These spraying nozzles are directed to all chocolate contaminated areas and the unit will only move forward once all parts have been successfully cleaned.

Frequent color changes when using chocolate coatings or alternate use of compound coatings and chocolate mean that the machine has to be cleaned in place. The ENROMAT® M6 – CIP chocolate enrober has all the technical and design advantages of the ENROMAT® M6 – Custom combined with a CIP (cleaning in place) option. It is made entirely from stainless materials and the pipes transporting the mass are easy to clean and dry. The machine has a CIP chocolate pump and an effective washing and drying system for wet cleaning.

Characteristics of the ENROMAT® M6 CIP:

- CIP variant of the Enromat® M6

- Integrated wash trolley above the wire belt

- Water circulation and treatment system with filter

- Short washing and drying times

- Spraying devices at all necessary points

- All enrobing components correspond to the Enromat® M6

- Length: 1.95m

- Available belt width: 820mm (32″) – 1800mm (70″)

A CIP version of the ENROMAT® M6 Magnum is also available.

Additional equipment

As well as the option to extend the enrobing line by the addition of a THERMO FLOW® plus cooling tunnel, a comprehensive range of extra equipment is available:

- bottom coaters and pre-coating machines

- top and polydimensional sprinkling devices

- strip coating device

- pressure curtain device

- product hold down drum roller

- wire-belt hold down device

- the DECORMATIC® automatic decorating system, Type DC4

- decorating rollers

- biscuit turn-over device

- product depositor and removal device

- truffle depositors

- truffle powdering and spiking stations

- cluster formers

- forming and extruding systems for pralines and bars

- chocolate tanks and pumps