Conbar® Candy Bars

Over the past 35 years, SOLLICH Conbar® lines have become the global market leaders in modern bar manufacturing. Contributory factors have included not only the progressive technology but also the reliability (greatly prized by our customers), user-friendliness and enormous flexibility of Conbar® equipment.

Our work on the production machines in our modern design and engineering facility guarantees the unique status of our machines in terms of technology and quality. This is where the manufacture of your products is tested under proper operating conditions. This is where we train your specialist staff. And this is where we help you with product development in respect of particular raw materials.

Fields of application

Conbar® bar manufacturing lines are suitable for nearly all products made from fatty masses, soft and hard-boiled sugar masses, aerated fatty and sugar masses, and a wide variety of mixtures containing nuts, fruit and cereals.

We are also able to supply the full range of cooking equipment for any application, whether in batches or continuously, from our CHOCOTECH-Candy Division.

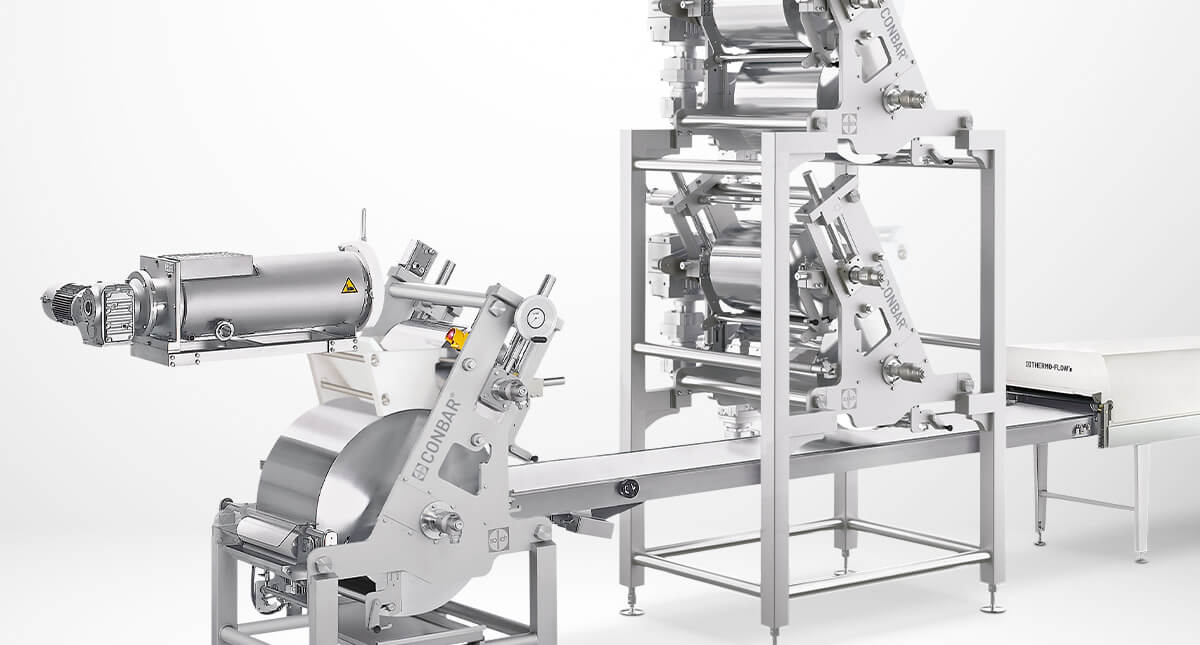

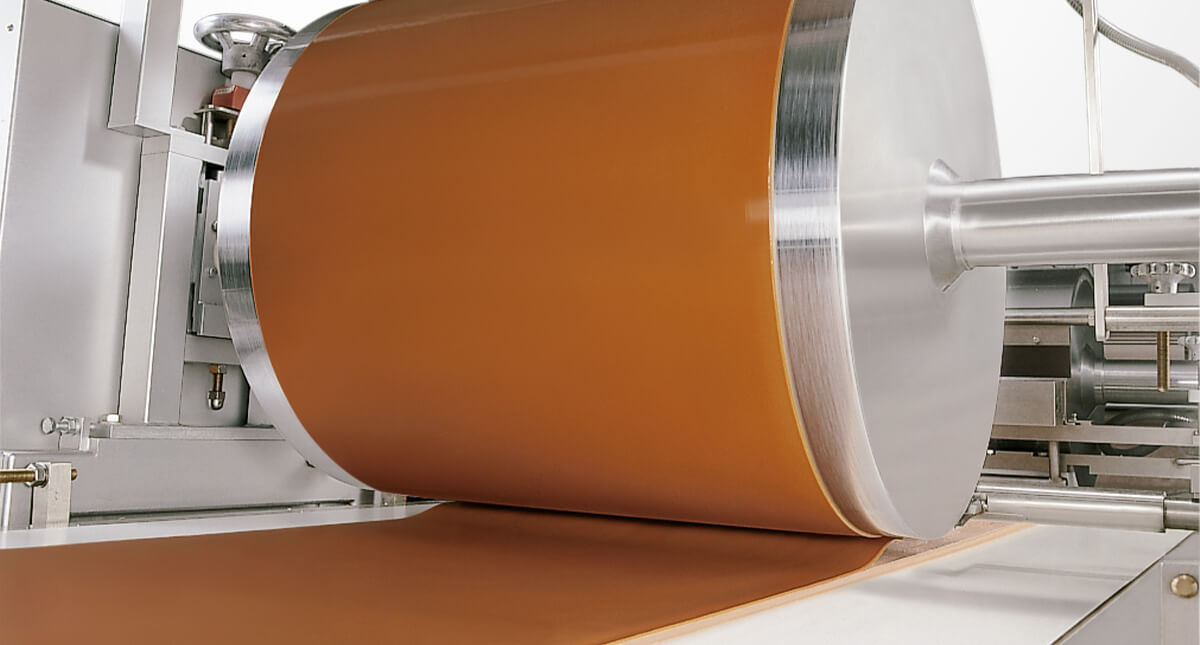

Conbar® roller formers allow:

- direct feed from the cooking plant or the mixer without the need for interim cooling

- cooling and moulding in a single machine

- gentle moulding without pressure, without changing the weight or structure of the mass

- easy changeover between products or changes to the product mass

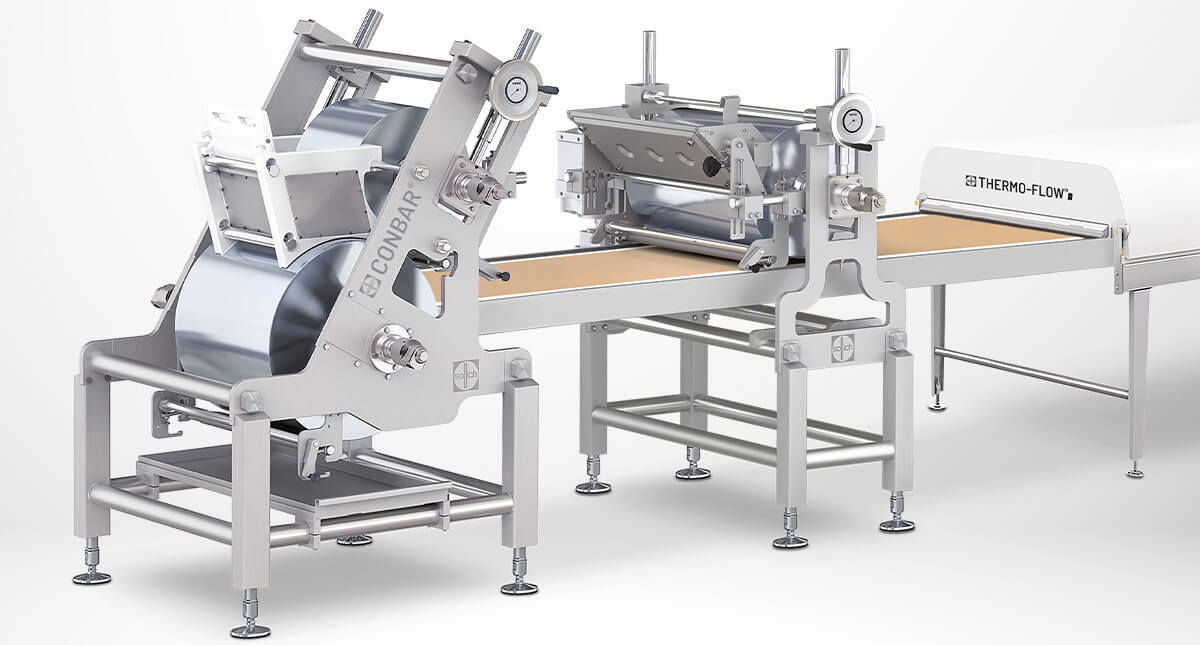

Alternative Conbar® roller formers

The following Conbar® roller formers are available for manufacturing cereal bars:

- Conbar® roller former Type WEB for pre-forming the first layer of cereal, located in front of the infeed table

- Conbar® Type WE, same as Type WEB, but positioned above the infeed table

- Conbar® roller former Type WET for forming a thin, usuallysecond, 2-5 mm layer of caramel, fudge or agar jelly on top of the cereal slab.

- Conbar roller former Type WEZK caramel or fudge mixed with nuts, raisines, cereals etc. are often formed to single or double layer bars.

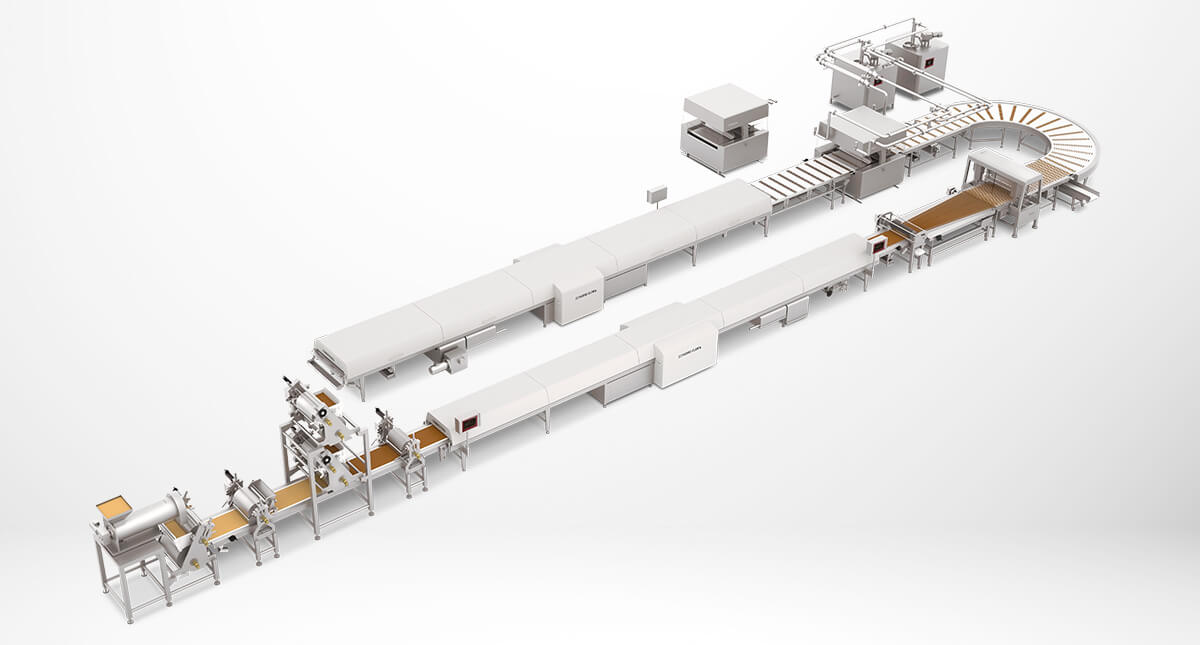

The Conbar® bar manufacturing lines may be extended with mixers, cooling tunnels, cutting plants and chocolate refining equipment.

The relevant cooking equipment is available in the range of products supplied by our sister company CHOCOTECH.

Product Brochure

Sollich-Conbar.pdf