Product Lines By Sollich

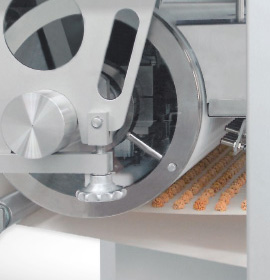

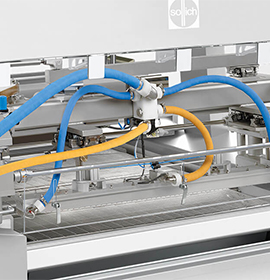

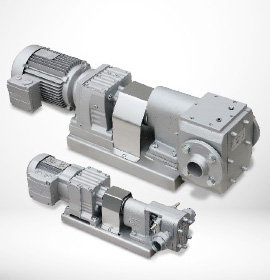

Sollich's comprehensive range of equipment includes a variety of machines - from forming, extruding, slitting & cutting equipment to fully automatic and robust enrobers, cooling tunnels, chocolate tempering machines as well as depositing lines for confectionery products. Complete bar lines are custom-made with precision and accuracy from the equipment above to ensure continuous efficient production of virtually any bar product.

News

Keep updated with the latest news by checking back and reading all the press releases from Sollich North America.