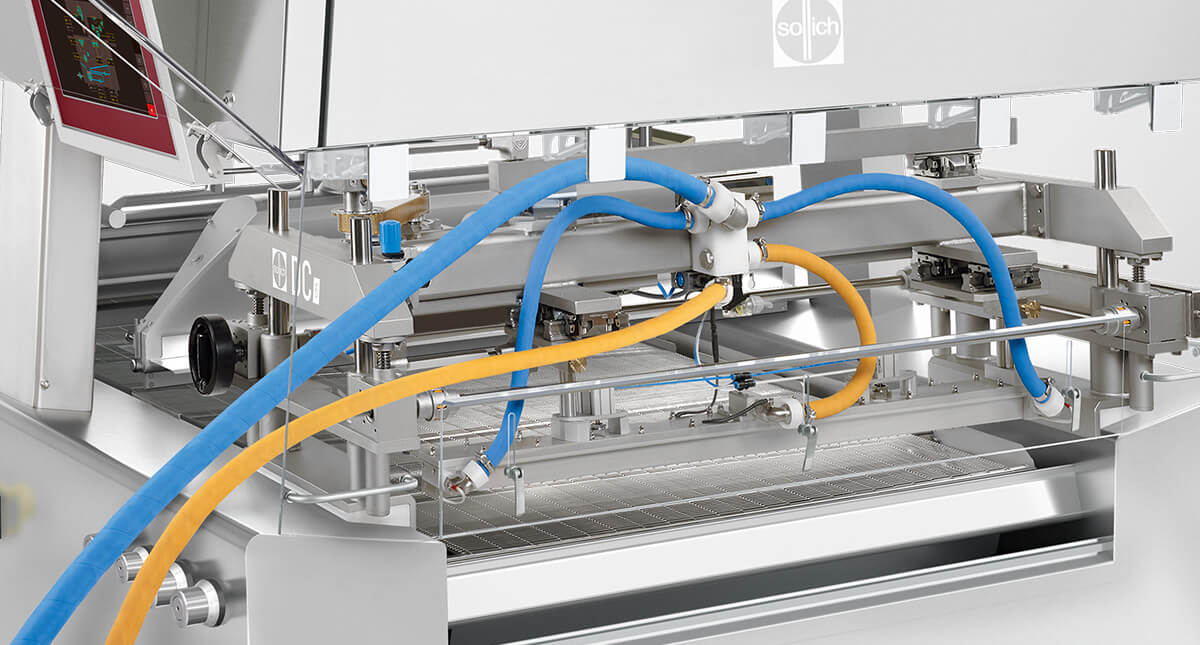

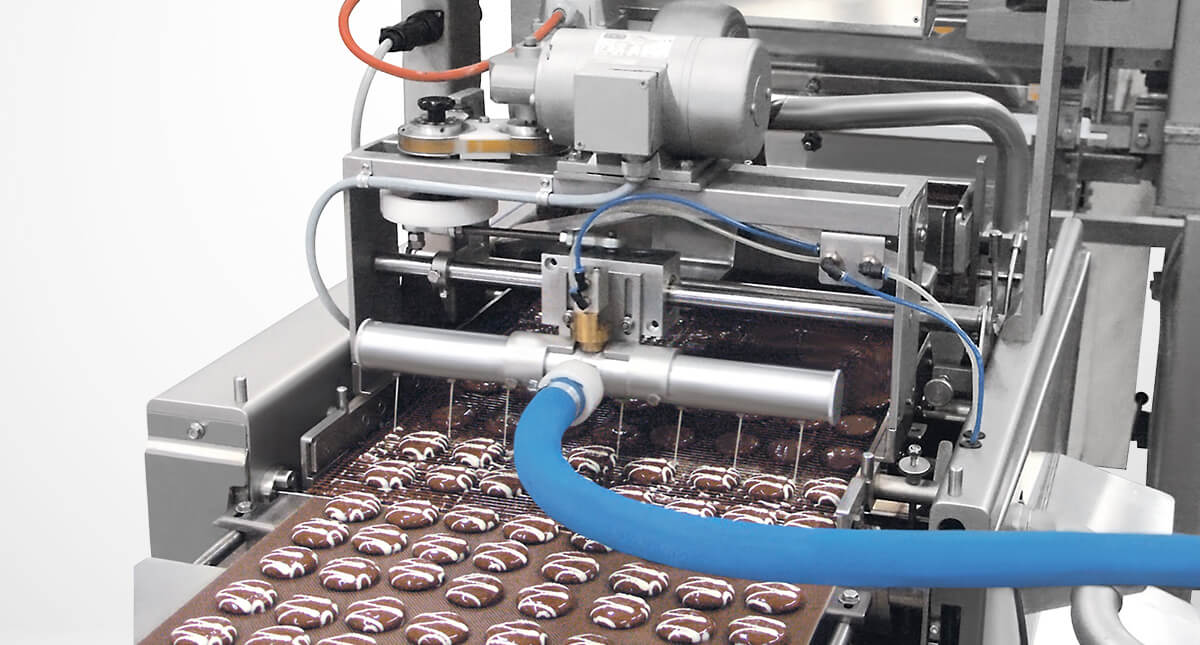

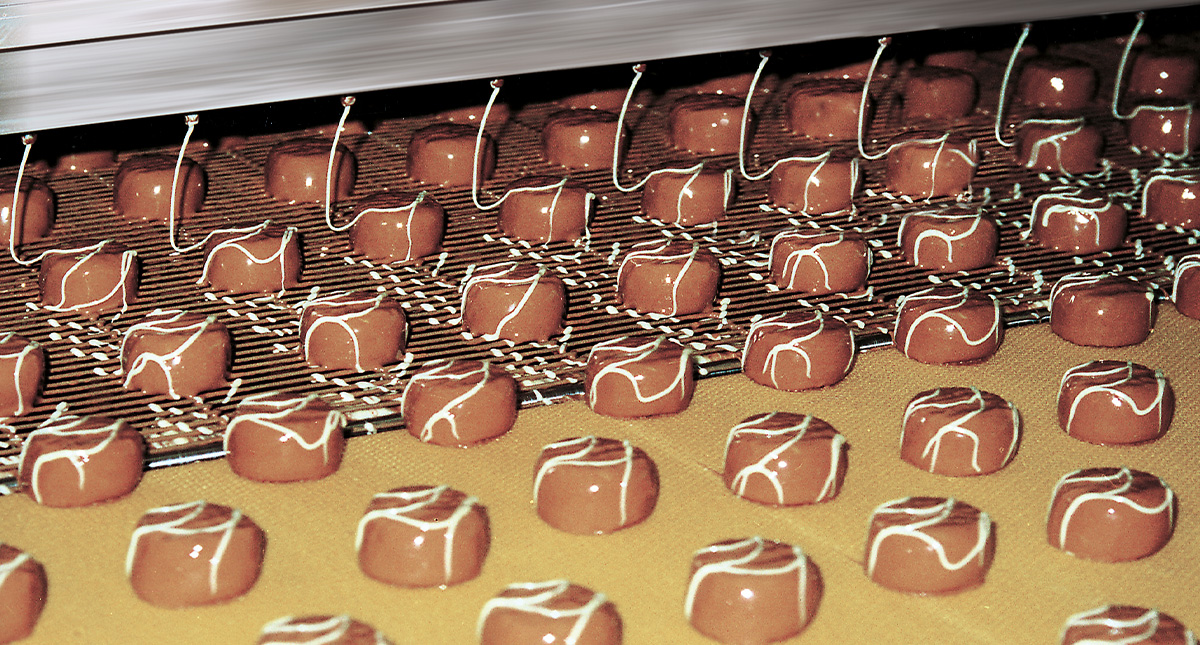

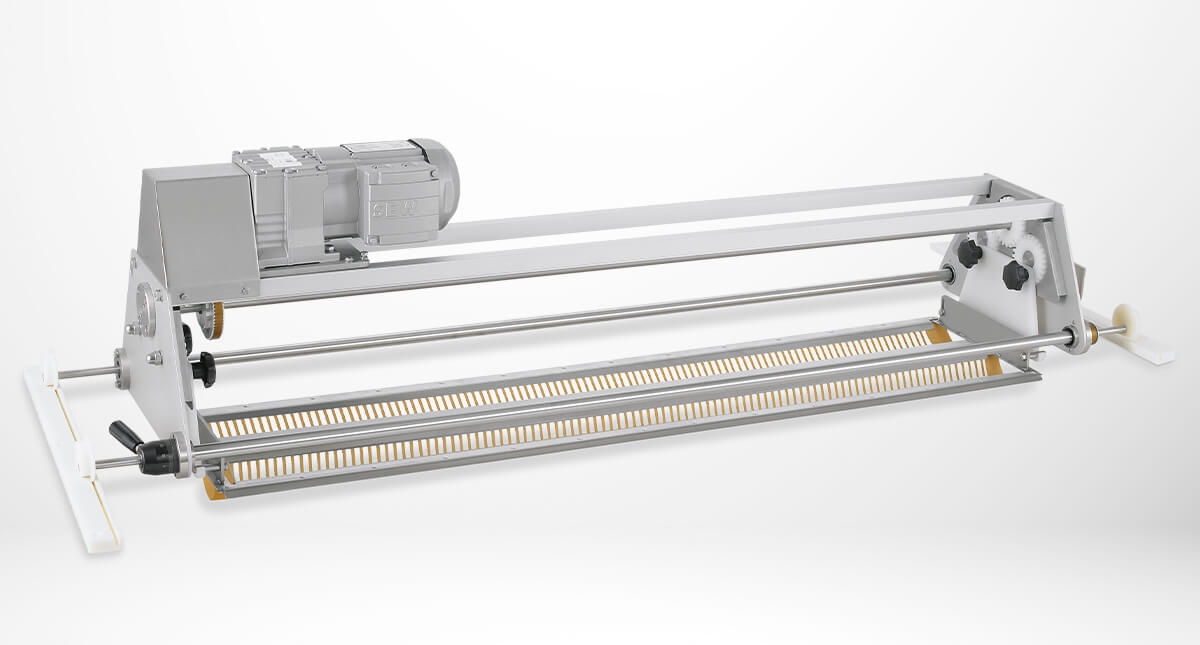

Decorating

Decorations are the face of your product. We offer comprehensive decoration and sprinkling solutions making your product unique.

News

Keep updated with the latest news by checking back and reading all the press releases from Sollich North America.