Caramel

Whether as a plain product like a piece of toffee or fudge, or in combination with other components like chocolate, bar layers with nuts, caramel has lots of applications. The basic recipe components are sugar, glucose, milk and fat. Depending on throughput and product there are different ways to produce caramel.

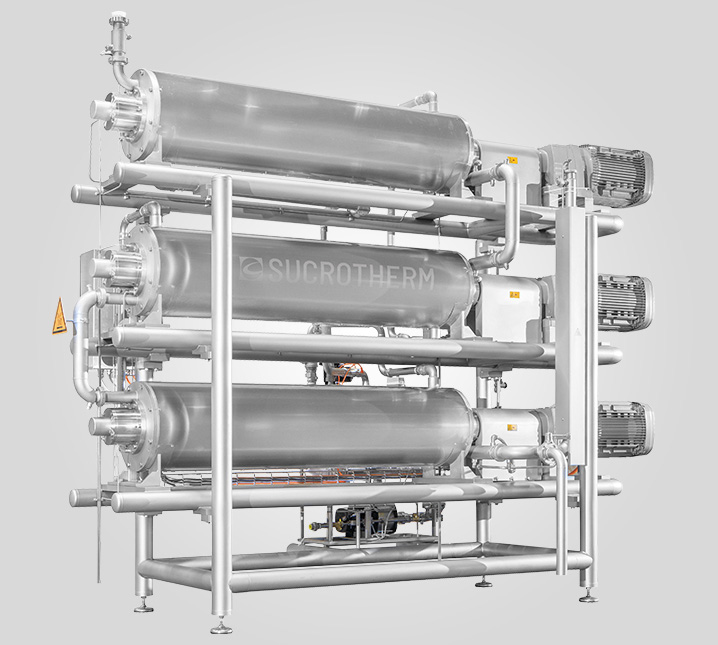

Continuous Manufacturing: a continuous production process is mainly used when it comes to high throughputs and multishift operations. CHOCOTECH can offer three continuous systems:

The Sucrofilm® / Caraflex® combination is the most flexible and usable for nearly all caramel types

Caralite® is a patented energy efficient system, suitable for caramel up to approx. 90 % solids

The YPP cooker combines cooking and caramelizing in a single process step

Batch-continuous Manufacturing: Carastar® is a batch cooker designed for flexible production and frequent recipe change overs. It is available in both automatic or manual execution.

News

Keep updated with the latest news by checking back and reading all the press releases from Sollich North America.