Chocolate Tempering

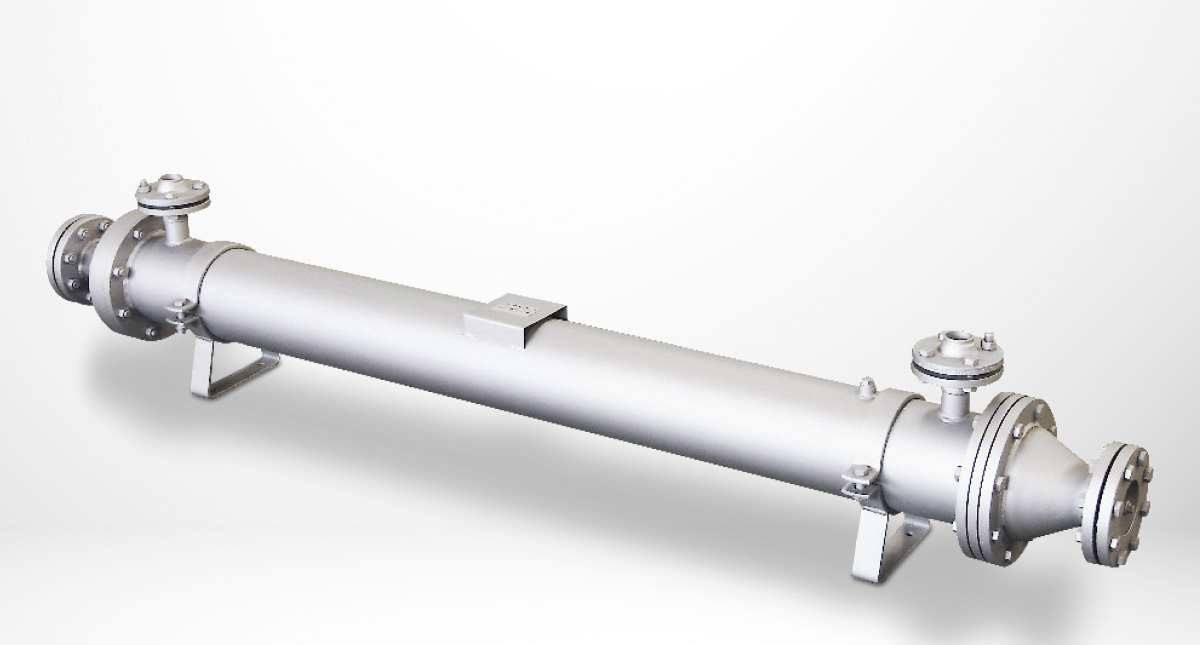

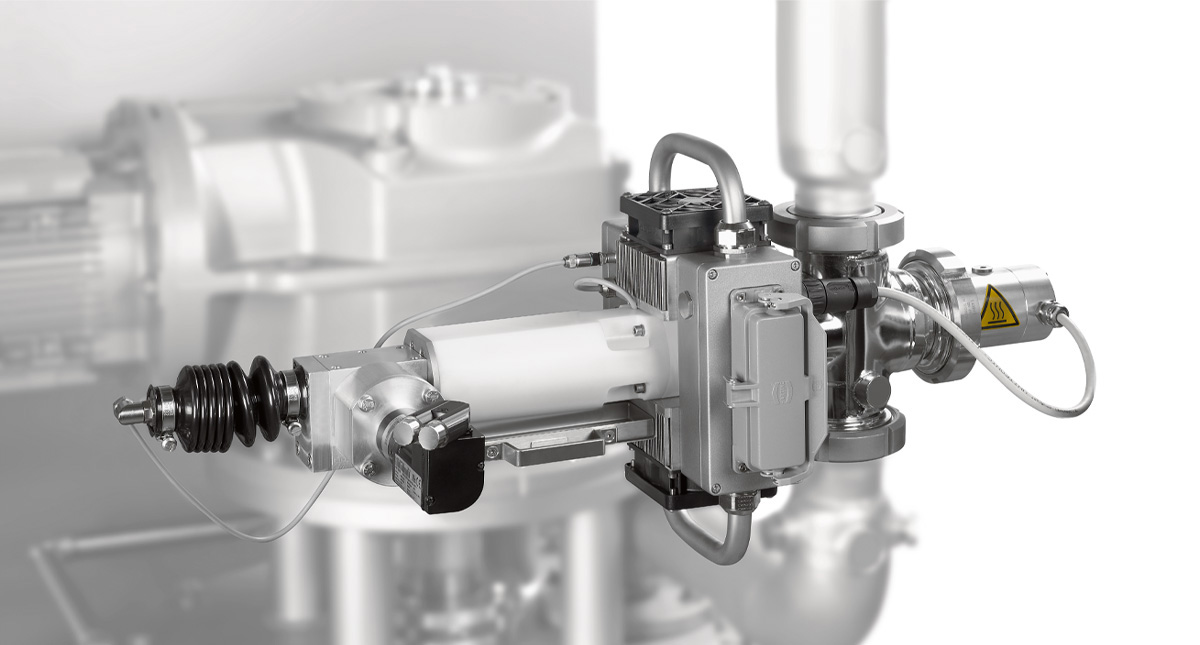

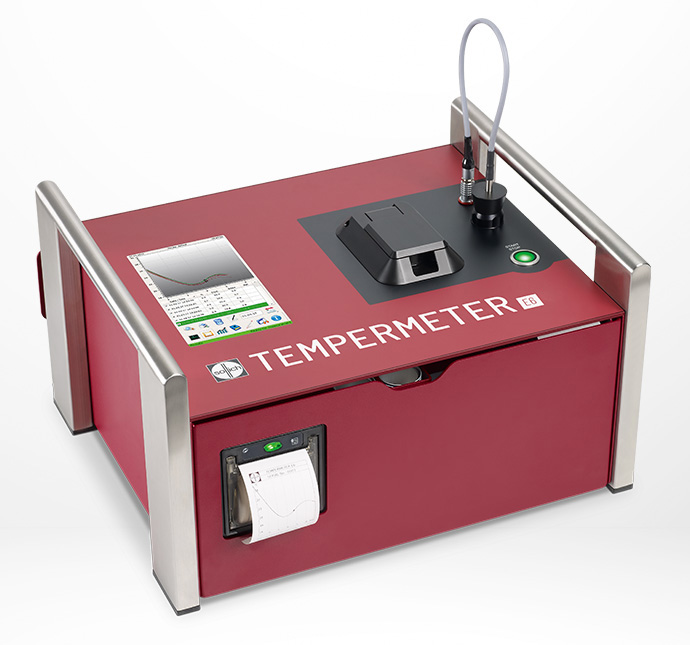

Tempering machines are at the heart of a chocolate processing system. This is where the foundation for a perfect product is laid. Sollich offers the correct machine for every application. Optimum shine, long shelf-life, good snap and a heat-resistant product are the result.

News

Keep updated with the latest news by checking back and reading all the press releases from Sollich North America.